Introduction

- I.4 -

ULTRAFEEDER

COMPLIANCE WITH EUROPEAN DIRECTIVES AND STANDARDS

The BTSR equipment comply with the safety requirements provided by Machinery Directive 2006/42/CE and

with the Electromagnetic Compatibility requirement provided by EMC Directive 2014/30/UE.

During the design and manufacturing stages of BTSR equipment, the relevant paragraphs of the following

Harmonized Standards have also been used as reference and guide line.

Applicable Directives

Machinery Directive

2006/42/CE

from 29/12/2009

Electromagnetic Compatibility Directive 2014/30/UE

from

20/04/2016

Main Harmonized Standards Applied

Safety of machinery - General principles for design - Risk assessment

and risk reduction

EN ISO 12100:2010

Electromagnetic compatibility (EMC). Part 6-2: Generic standards -

Immunity for industrial environments.

EN 61000-6-2:2005

Electromagnetic compatibility (EMC). Part 6-4: Generic standards -

Emission standard for industrial environments.

EN 61000-6-4:2007

Electrical equipment for measurement, control and laboratory use -

EMC requirements -- Part 1: General requirements

EN 61326-1:2012

Safety of machinery. Electrical equipment of machines. Part 1:

General requirements.

EN 60204-1:2006/AC:2010

Safety of machinery. Safety-related pars of control systems. Part 1:

General principles for design.

EN ISO13849-1:2015

Safety of machinery. Safety-related pars of control systems. Part 2:

Validation.

EN ISO13849-2:2012

Noise Levels

The ULTRAFEEDER devices have been designed and manufactured to reduce the noise to minimum levels

during operation. Weighted A acoustic pressure level generated by the machine and measured (

following the

criteria defined by the standards in force

) at the operator working zones, during normal operation, is less

than 70 db (A)

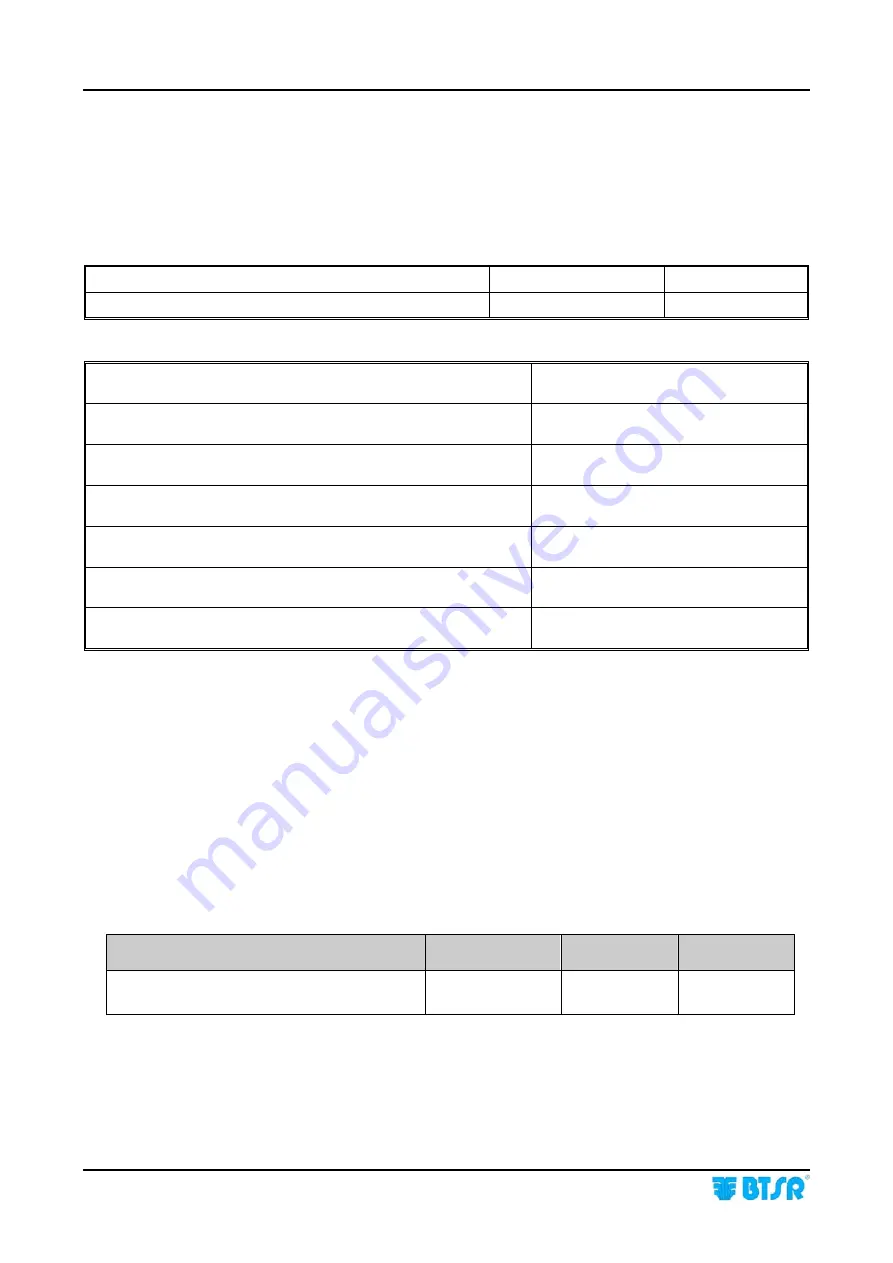

SAFETY AND RELIABILITY OF CONTROL SYSTEMS

Within the ULTRAFEEDER device, the only safety control system (

motor locking prior to carry out the

threading operation

) has been implemented according to the principles of the Harmonized Norm EN ISO

13849-1:2015. The following table shows the values of Category and of Performance Level (PL)

implemented (

with respect to the Required Performance Level (PLr) resulting from the risk assessment

).

The PL calculation has been carried out by means of the “SISTEMA” (IFA) software.

Safety function

Category

PL

PLr

Wheel motor safety stop during the threading

operation.

1 b

b

The PL value calculation and the relevant “SISTEMA” report are included within the Technical File of the

ULTRAFEEDER device.

Summary of Contents for ULTRAFEEDER

Page 1: ...ULTRAFEEDER YARN CONTROL SYSTEM Operating Manual ENGLISH Rev 4 1 February 2017 ...

Page 40: ...Technical Data and Installation 2 28 ULTRAFEEDER Page intentionally left blank ...

Page 72: ...ULTRAFEEDER Troubleshooting and Maintenance 4 6 ULTRAFEEDER Page intentionally left blank ...

Page 78: ...YTT Device 5 6 ULTRAFEEDER Page intentionally left blank ...