6.Periodic Inspection/Maintenance

[How to Use Booster Cable]

Do not reverse the cable connection

A

CAUTION ·---------

....

________________

.....

• When a booster cable has to be used or when cables are connected again after an battery is replaced,

be careful not to c) and (-) terminals backwards. Such wrong-connection will cause spark and

damage to each component.

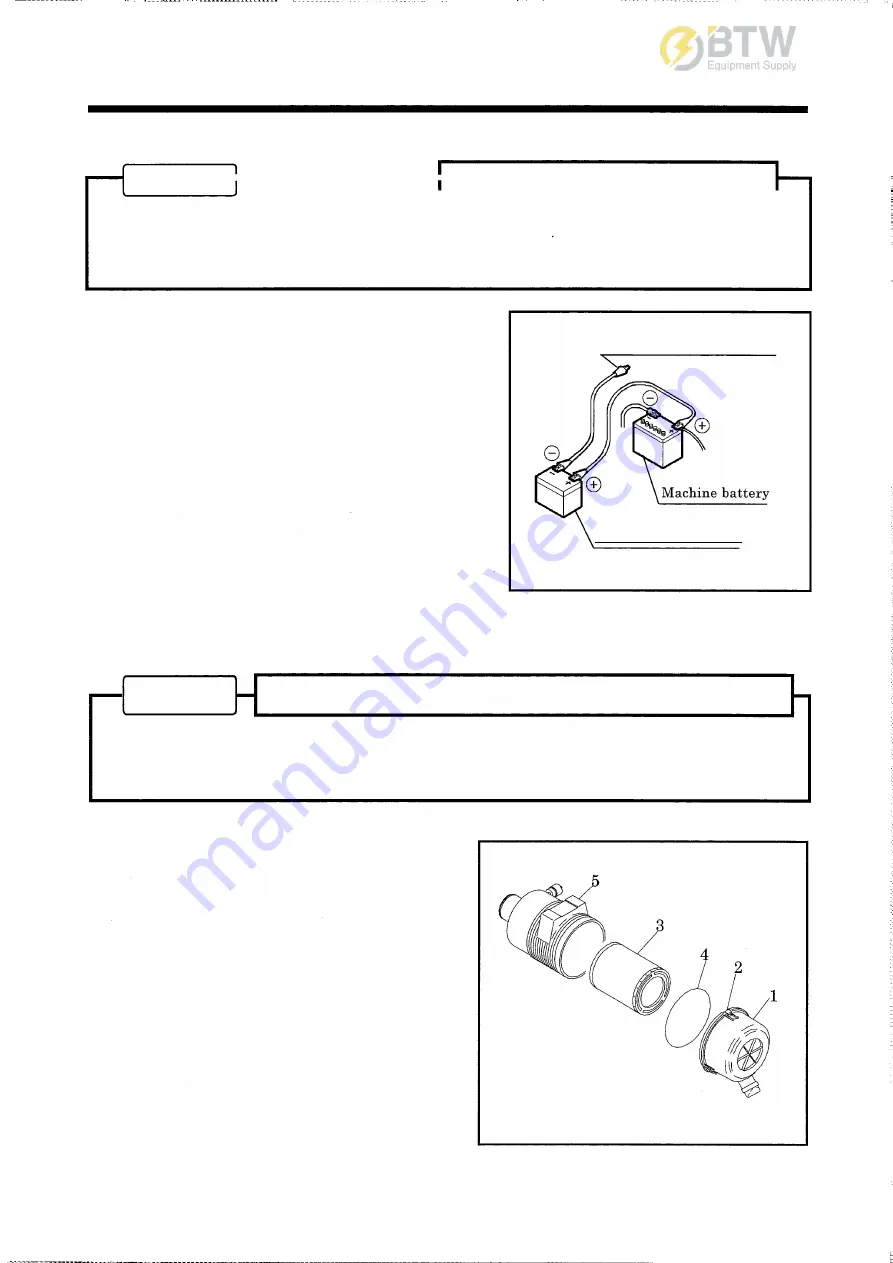

<Procedure for using a booster cable>

CD Stop the engine.

® Connect one end of the ( +) cable to the ( +) terminal of

the machine battery.

® Connect the other end of the ( +) cable to the ( +)

terminal of the external battery.

@ Connect one end of the (-) cable to the (-) terminal of

the external battery.

@ Connect the other end of the (-) cable to the engine

block of the machine.

@ Start up the engine.

(]) Disconnect the booster cable by following the

procedure back in the reverse order.

6.5.5 Check and clean a clogging air filter element

[Every 250 hours]

Connect to the engine block

of the unit

External battery (12V)

TR0345E

IMPORTANT

Cleaning of air filter element should be perfectly performed

• Clogged or cracked or pitted element could allow entrance of dust into engine and compressor to

cause earlier wear of moving parts. Periodical inspection and cleaning of element should be

performed to maintain life of compressor and engine long.

<Procedure>

CD After removing the cap "1'' by loosening its latch

"2'' , clean its interior properly.

® Take out element "3", and clean it.

® When installing the cap after it is cleaned, hold

the case "5" securely by hand so that O·ring "4"

may not protrude from it, and retighten it after

checking and confirming that the latch hook for

fixing the cap is engaged to the case.

• Not limited to the above, be sure to replace any

element with a new one in the case in which it

is heavily stained.

(For part numbers,refer to 6.4)

6-9

A100397-1

BTW Equipment Supply • www.btwequipmentsupply.com • ORDER PARTS ONLINE