Boiler block assembly

8

Logano GE515 - We reserve the right to make any changes due to technical modifications.

40

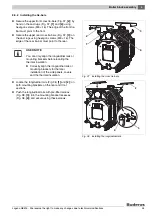

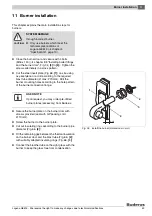

Prepare the installation of side panels by initially fitting

the hinged covers (front) of the side panels.

z

Pre-assemble the hinges of the hinged covers of the

side panels using 2 self-tapping screws each.

z

Hook the hinge hooks (Fig. 49,

[1]

) on the hinged

cover of the side panel into the cut-out of the front

side panel and secure with self-tapping screws.

z

Hook the tensioning spring (Fig. 49,

[2]

) into the side

panel and the hinged cover of the side panel.

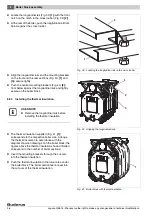

z

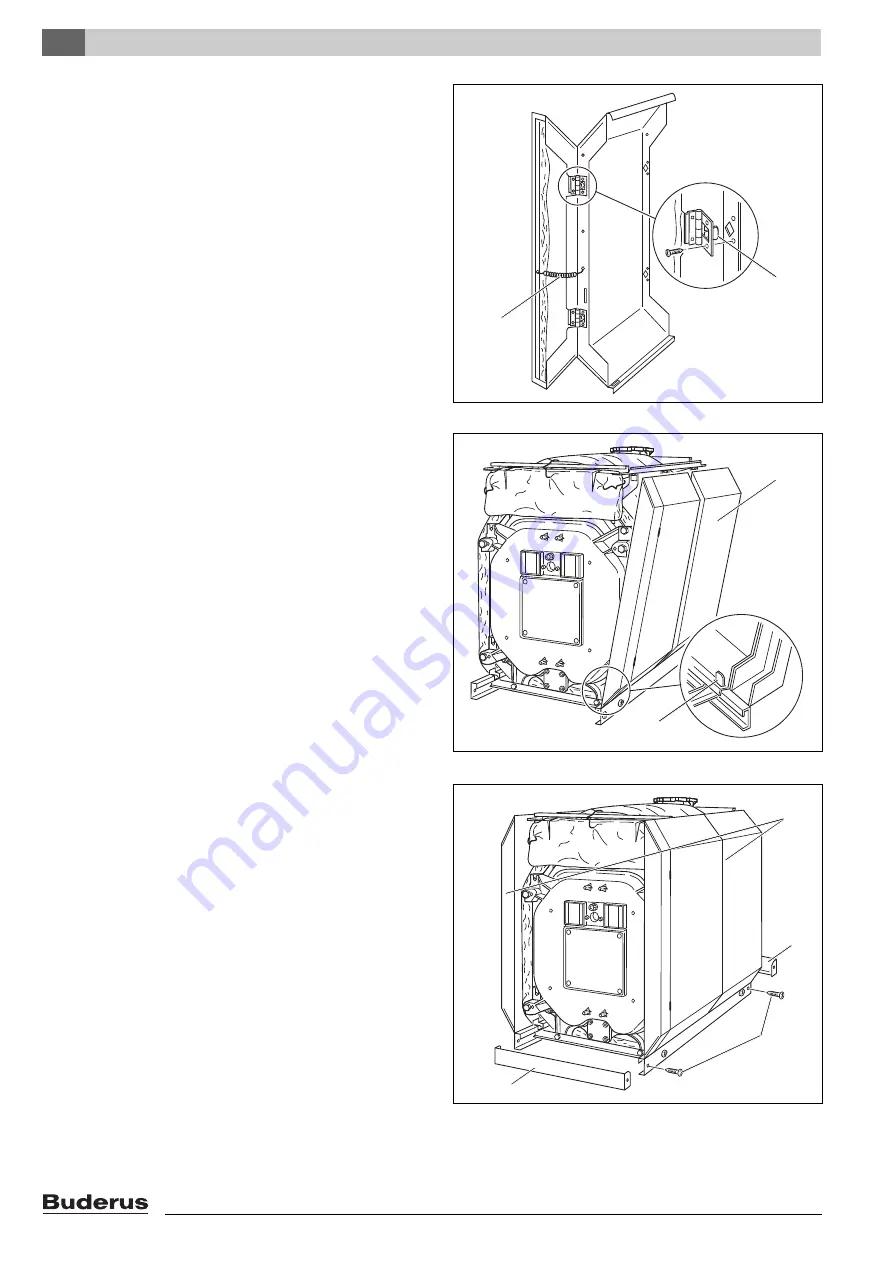

Hook the front side panels (Fig. 50,

[2]

) into the l.h.

and r.h. bottom of the angled tabs on the plinth rails

(Fig. 50,

[1]

), then push them at the top over the

angled part of the longitudinal rails.

z

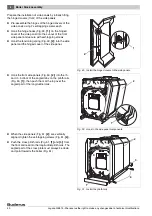

When the side panels (Fig. 51,

[2]

) are vertically

aligned, tighten the self-tapping screws (Fig. 51,

[4]

).

z

Push the cross plinth rails (Fig. 51,

[1]

and

[3]

) from

the front and rear into the longitudinal plinth rails. The

angled part of the cross plate must always be down

and point towards the boiler (Fig. 51).

Fig. 49 Install the hinged covers to the side panels

1

2

1

2

Fig. 50 Hook in the side panel components

2

1

Fig. 51 Install the plinth rails

1

2

4

3