Installing the control device

10

Logano GE515 - We reserve the right to make any changes due to technical modifications.

47

10.2 Installing the temperature sensor set

and burner cable

z

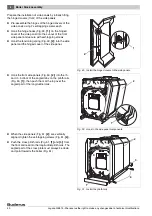

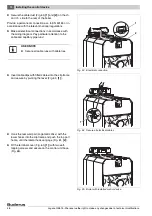

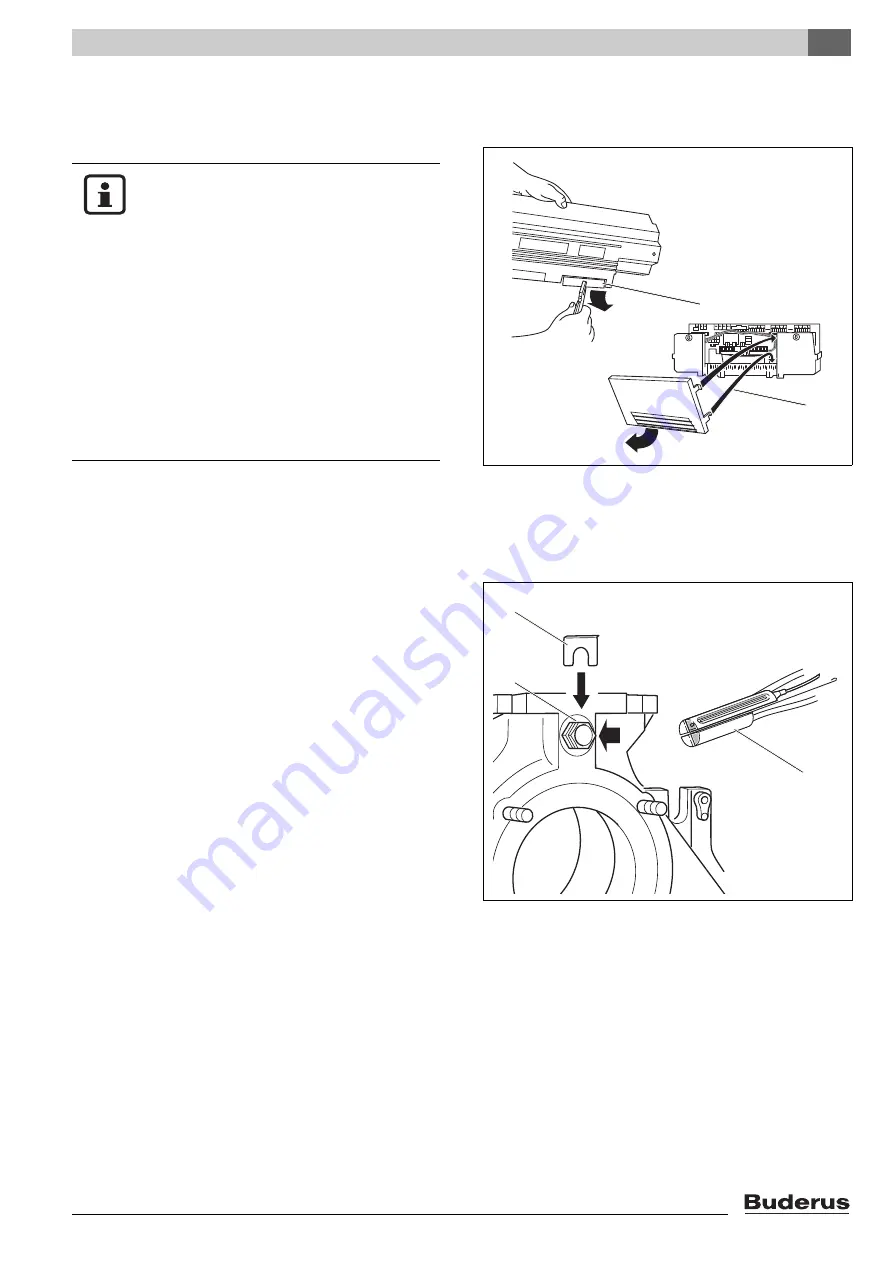

Where necessary remove any knockouts (Fig. 61,

[1]

) in the back of the cable duct (Logamatic 33xx) or

from the rear wall (Logamatic 43xx) (Fig. 61,

[2]

).

z

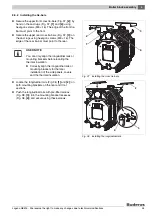

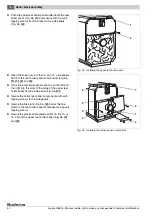

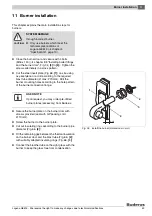

Insert the capillary pipes through the cable gland and

unroll to the required length.

The sensor well has already been sealed into the flow

connection coupler (see chapter 8.5 "Seal-in the sensor

well", page 27).

The temperature sensor set (three sensors, one sensor

blank Fig. 62,

[1]

) connected to the control unit is fitted

into the R ¾" sensor well.

z

Route the capillary sensor to the measuring point on

the boiler and insert it into the sensor well as far as it

will go (Fig. 62,

[2]

); then secure the assembly with a

sensor securing device (Fig. 62,

[3]

).

Fig. 61 Prepare the cable duct

2

1

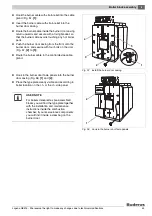

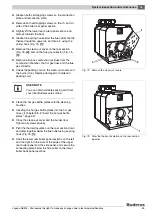

USER NOTE

Observe the following when connecting

the control device:

z

Carefully route the cable ducts and

capillary pipes.

z

Never kink capillary pipes during

installation.

z

Work on heating systems must only be

carried out by qualified personnel. If

you are not suitably qualified, let an

electrical contractor carry out the

electrical connections.

z

Observe all local regulations.

Fig. 62 Install the temperature sensor set

1

2

1

2

3