6

Installing the boiler

Logano plus GB312 – 6 720 806 273 (2013/01)

26

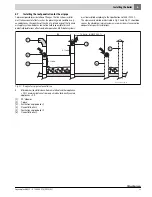

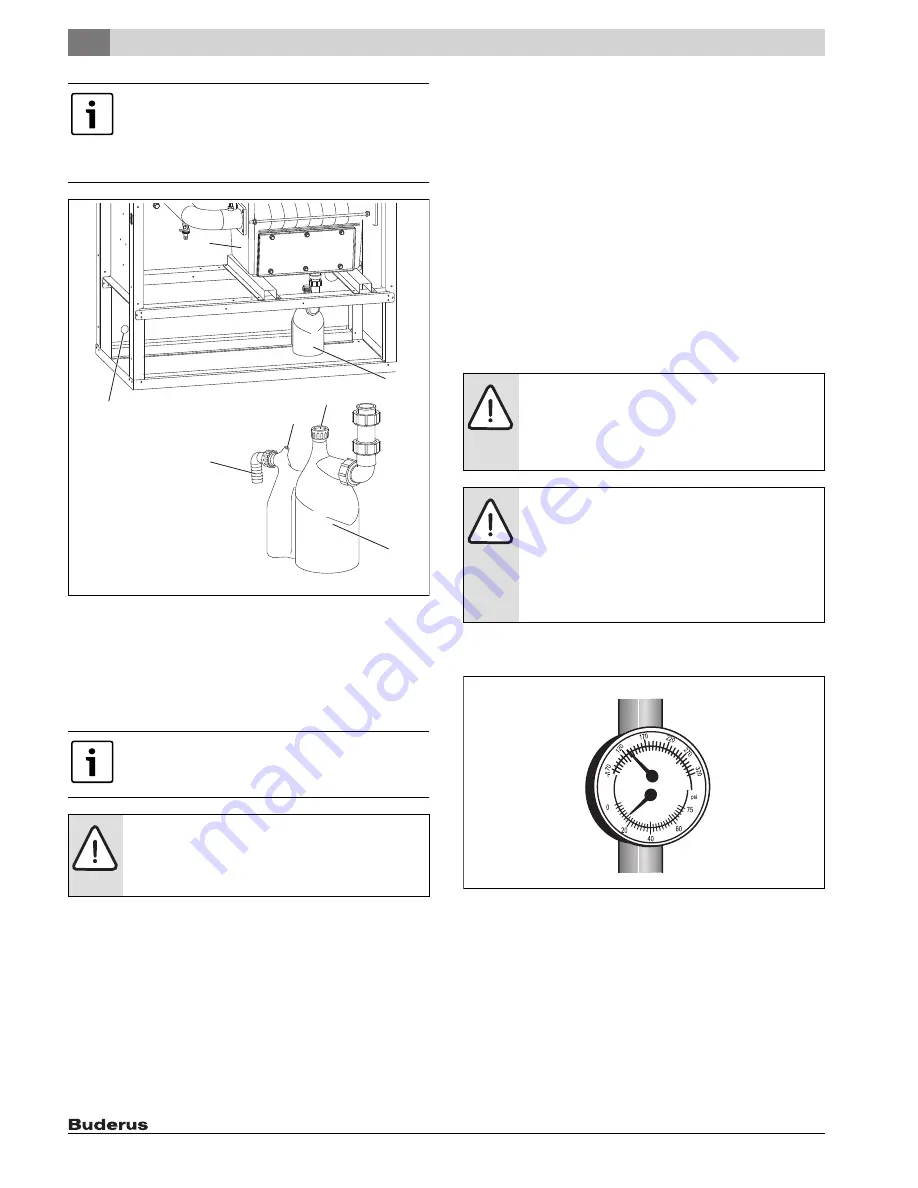

Fig. 27 Installing the condensate drain

[1]

Siphon (condensate trap)

[2]

Condensate pan

[3]

Siphon outlet to neutralizing system or drain line

[4]

Siphon vent

[5]

Cap

[6]

Hole for condensate drain hose

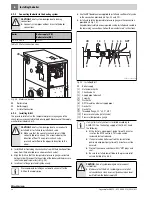

6.10

Filling heating system and checking for leaks

Before commissioning the heating system, check it for soundness to

avoid leaks occurring during operation. Pressurize the heating system

with a pressure that is slightly less than the response pressure of the

pressure relief valve.

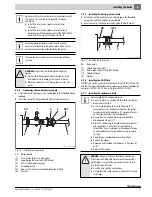

pH requirements

• The optimal range of pH for the boiler system fluid is 7.0 to 8.5.

• pH must be checked and recorded at each yearly maintenance in

order to keep the warranty valid.

• Failure to do so will immediately void the warranty on the heat

exchanger.

• Adjusting pH if it is out of range (7.0ph to 8.5pH)

– Flush system with fresh municipal water, run the system up to

temperature for an hour and check pH

OR

– Add Rhomar Protek 922 to the system at a volume of 1 gallon of

Protek 922 to 25 gallons of system volume.

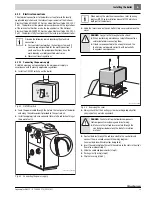

▶ Carry out a leak test in accordance with local authority having

jurisdiction regulations.

Fig. 28 Pressure/temperature gauge

A condensate neutralizer is available as an accessory.

▶ Install the neutralizing system in accordance with the

installation instructions.

▶ Install the trap supplied to the condensate pan drain

outlet.

Condensate may possibly escape through the vent.

▶ Be sure to run the drain pipe from the siphon so that

it slopes downwards.

DANGER:

Danger of fatal accident due to poisoning!

▶ It is essential that you use the boiler's built-in siphon.

▶ Make sure that the condensate from the flue system

drains correctly.

7 747 010 720-23.1RS

1

6

1

2

3

4

5

CAUTION:

Risk of system damage due to scale

formation in the boiler!

▶ Heed the information provided in the

"7747010721_GB312_Water Quality

Requirements.pdf"

CAUTION:

Risk of system damage due to excess

pressure when testing for leaks!

Pressure, control and safety equipment may be

damaged by excessive pressure.

▶ When you carry out a leak test, make sure that no

pressure, control or safety device that cannot be

isolated from the boiler's water chamber is installed.

7 747 010 720-24.2RS