5

Installing the boiler

Logano plus GB402 - Subject to technical modifications!

16

5

Installing the boiler

5.1

Installation requirements

Preventing noise disturbance for end-users

B

Where the boiler ambience is sensitive to noise (e.g.

residential units), use the silencer options offered by

the manufacturer (flue gas silencers, compensators).

5.2

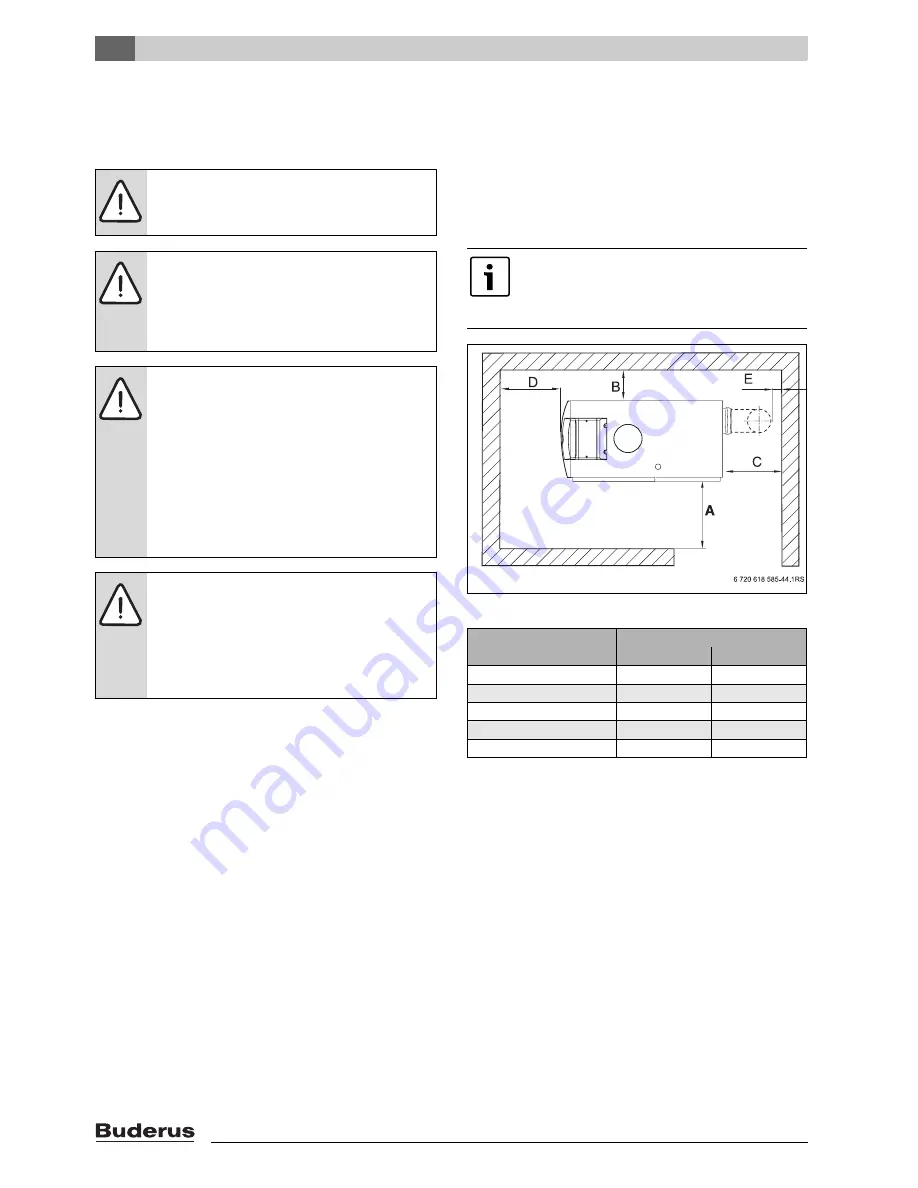

Recommended wall clearances

When determining the installation location, take the

clearances for the flue and the connection pipe assembly

into consideration (

Æ

Fig. 7 and Chapter 6 flue system

connection and the pipework on the water and gas sides).

Fig. 7

Wall clearances in the installation room

NOTICE:

System damage due to frost!

B

Set up the heating system in a room safe

from the risk of frost.

DANGER:

Dangers through explosive and

easily flammable materials.

B

Never use or store combustible materials

(paper, curtains, clothing, thinners, paints,

etc.) in the vicinity of the boiler.

NOTICE:

Risk of boiler damage from

contaminated combustion air.

B

Never use chlorinated cleaning agents or

halogenated hydrocarbons (as contained

in spray cans, solvents, cleaning agents,

paints and adhesives, for example).

B

Never store or use such materials in the

boiler room.

B

Avoid very dusty atmospheres (building

dust).

NOTICE:

Boiler damage through

overheating.

Excessive ambient temperatures can result in

heating system damage.

B

Ensure ambient temperatures above 0 °C

and below 35 °C.

Where applicable, allow extra wall

clearances for additional components, for

example DHW cylinder, pipe connections or

other components on the flue gas side etc.

Dimension

Wall clearance (mm)

minimum

recommended

A

700

1000

B

150

400

C

1)

1) This clearance dimension applies independently of the installed

flue system.

-

-

D

700

1000

E

1)

150

400

Tab. 7

Recommended and minimum wall clearances

(dimensions in mm). Maintain minimum

clearance, dimension E.