6

Installation

Logano plus GB402 - Subject to technical modifications!

21

6.5

Making the heating circuit connection

6.5.1

Connecting the flow

B

Insert a gasket between the flange on the boiler and the

threaded mating flange on the flow.

B

Secure the flange connection with 4 screws, washers

and nuts.

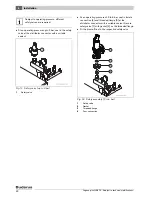

Fig. 13 Fitting the flow (VK)

6.5.2

Installing the safety assembly (on site)

B

Seal in distributor [2] at flow connector [1] using a

suitable sealant.

B

Remove the union at the cap valve fitting [3].

B

Fit union with gasket to connector of fitting manifold [4]

and secure to the cap valve on the distributor.

B

Level the fitting manifold and fit maximum pressure

limiter [5].

Fig. 14 Installing the fitting manifold

1

Flow connector

2

Distributor

3

Cap valve

4

Fitting manifold complete with cap valve ¾ Inch

5

Maximum pressure limiter

NOTICE:

System damage due to leaking

connections!

B

Install all lines free from stress to the boiler

connections.

B

Use new gaskets if fittings need to be

undone.

B

Only tighten flanges on the heating flow

and return after the connections have been

made.

B

Before installing the pipe connections,

check connections and gaskets on the

boiler for possible damage.

Boiler flow (VK)

Boiler return (RK)

DN80

PN6 standard flange EN1092

Tab. 8

Water connection dimensions

NOTICE:

System damage through incorrect

installation.

B

Always fit a safety valve and the automatic

air vent valve or the safety assembly to the

flow.

The safety assembly (accessory) comprises

an automatic air vent valve and a pressure

gauge. As an option, it may be converted for

use with a safety valve (additional accessory)

and a fitting manifold for the maximum

pressure limiter.

If these accessories are not used, a safety

valve, pressure gauge and an automatic air

vent valve must generally be installed in the

flow, upstream of the first shut-off valve.