7

Commissioning the heating system

Logano plus GB402 - Subject to technical modifications!

35

7.10.3 Checking the CO

2

setting under full load

(70-80 %)

B

Press

to increase the boiler output in percent.

B

Read off load at the RC35 or via the service key.

B

Wait until at least 70-80 % of the load has been

reached.

B

Recheck the CO

2

content and correct if required

(

Æ

Chapter 7.10.1).

Fig. 35 Accessing full load at the BC10

7.11 Switching the status display on the

BC10 to show the boiler

temperature status

B

Press

to change to the next status display.

The current operating pressure

P1.7

is displayed.

B

Press

to change to the next status display.

Operating status

0Y

(display code) is shown.

B

Press

to change to the next status display.

The boiler temperature is displayed.

7.12

Returning to operating mode from

the flue gas test

B

Press

again to terminate the flue gas test.

B

Return to operating mode on the RC35.

B

Close the flap on the RC35.

B

If the boiler is designed for operation with the

Logamatic 4000 control system, remove the RC35

again. Starting the Logamatic 4000 control system.

7.13

Recording actual values

B

Carry out the following tests at a test port in the boiler

flue connection and enter the results in the

commissioning report (

Æ

Chapter 7.18):

– Draught

– Flue gas temperature t

A

– Air temperature t

L

– Net flue gas temperature t

A

- t

L

– Carbon dioxide content (CO

2

)

or oxygen content (O

2

)

– CO value

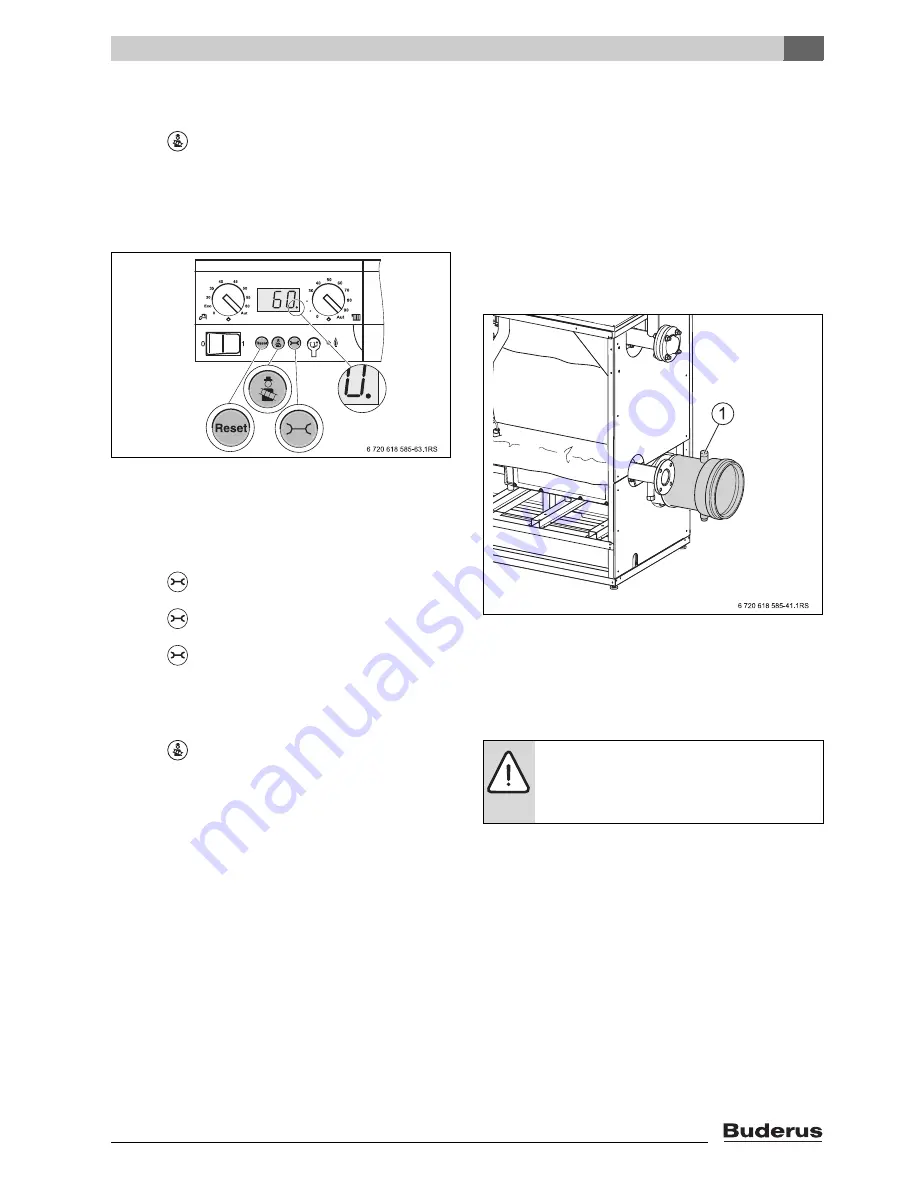

Fig. 36 Recording actual values

1

Position of the test port in the flue

7.13.1 Draught

The required draught for the installed balanced flue

system must not exceed 100 Pa (1.0 mbar).

7.13.2 CO value

CO values in an air-free state must be below 400 ppm or

0.04 % vol.

Values above 100 ppm indicate and incorrect burner

adjustment, incorrect appliance setup, burner and/or heat

exchanger contamination or burner faults.

B

Identify and eliminate the cause.

DANGER:

Risk to life from toxic flue gases

escaping.

B

Only operate the boiler with a chimney or

flue gas system (

Æ

Tab. 3, page 11).