8

Inspection and service

Logano plus SB325 – 6 720 806 328 (2013/07)

33

▶ Remove all loose combustion residues from the flue gas collector.

▶ Check whether the siphon is filled with water.

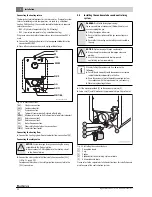

Fig. 39 Cleaning cover on the flue gas collector

[1]

Cleaning cover

[2]

Condensate drain

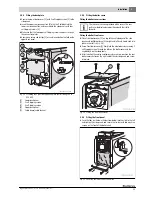

8.3.4

Replacing the gasket in the flue gas collector and the

reversing chamber door

▶ Remove the old gasket and adhesive residues.

▶ Trim the new gasket.

▶ Affix the new gasket directly to the edges of both the flue gas collector

cover and the reversing chamber door.

▶ Allow abutting edges to overlap.

▶ Cut off abutting edges at an angle of 45°.

▶ Press diagonally abutting edges together leaving no gap.

8.3.5

Fitting the cleaning cover on the flue gas collector and

reversing chamber door

▶ Replace the gasket in the reversing chamber door and the cleaning

cover.

▶ Position cleaning cover of the flue gas collector.

▶ Tighten wing nuts.

▶ Position the reversing chamber door and seal by screwing tight.

▶ Secure the thermal insulation.

▶ Mount the burner.

▶ Fit the front panels.

▶ Restart the heating system.

8.3.6

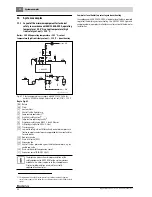

Wet-cleaning the boiler

When wet-cleaning, use a cleaning agent appropriate for the level of

contamination.

For wet cleaning, proceed according to the manufacturer's instructions.

Liquid cleaning residues can be drained off through the condensate

drain pipe on the flue gas collector.

▶ Disconnect the heating system from the power supply.

▶ Close the fuel supply. Disconnect the neutralising system and siphon

prior to wet cleaning.

▶ Cover the control panel with foil to prevent spray from entering it.

▶ Clean the boiler according to the instructions of the cleaning

equipment manufacturer.

After cleaning:

▶ Reconnect the condensate drain pipe.

▶ Reconnect the condensate connection.

▶ Check gaskets on combustion chamber door and replace if required.

▶ If the flue gas collector's cleaning cover is opened, the gasket on the

cleaning cover has to be replaced (

chapter 8.3.4).

▶ Close and secure the combustion chamber door (

chapter 5.10.1,

page 24).

▶ Close and tightly seal the cleaning cover on the flue gas collector (

chapter 8.3.5).

▶ Continue to ensure adequate ventilation of the boiler room.

▶ Remove the foil from the control unit.

▶ Restart the heating system.

Replace the gasket in both the flue gas collector cover

and the reversing chamber door during the annual

service.

Tighten the nuts to secure the flue gas collector and the

reversing chamber door to the extent that the gasket

pressure is at least 35 %. For a gasket which is 10 mm

thick, it must be compressed to at least 3.5 mm,

DANGER:

Risk of poisoning through escaping gases.

Flue gas can escape during operation if the reversing

chamber door, flue gas collector and condensate drain

pipe are not correctly sealed.

▶ Carefully seal the reversing chamber door and flue

gas collector with the cleaning cover and the

condensate drain with the siphon and hydraulic seal.

6 720

8

04

3

49-17.1ITL

1

2

NOTICE:

System damage through moisture in the

control unit.

If moisture enters the control unit, it will be damaged.

Never allow any spray to enter the control unit.

▶ Ensure that you only spray cleaning agent onto the

heating surfaces of the hot gas flues and the

combustion chamber.

NOTICE:

System damage through cleaning agents in

connected components.

If liquids displaced by the cleaning agents are

channelled through connected components, e.g.

siphon, neutralising system etc., these components may

become inoperable or be damaged.

▶ Protect or remove connected components.

For wet cleaning (chemical cleaning), observe the

operating instructions and safety instructions of the

cleaning equipment and cleaning agent.

For wet cleaning, ensure that the cleaning agent is

chloride-free.

▶ Observe the safety instructions of the cleaning agent.

For wet cleaning, we recommend high-pressure cleaning

equipment.

▶ Never drain cleaning residues through the neutralising

system.

▶ Do not block up the condensate drain (

Fig. 39)

when cleaning.