2002 Buell P3: Engine

3-59

HOME

INTAKE CAM GEAR BUSHING IN

GEARCASE COVER

.

See

Figure 3-98.

The intake cam gear bushing must be

installed in its gearcase cover bore using an arbor press. You

will need to orient the bushing in a specific position of rotation

within the cover bore according to the following procedures:

1.

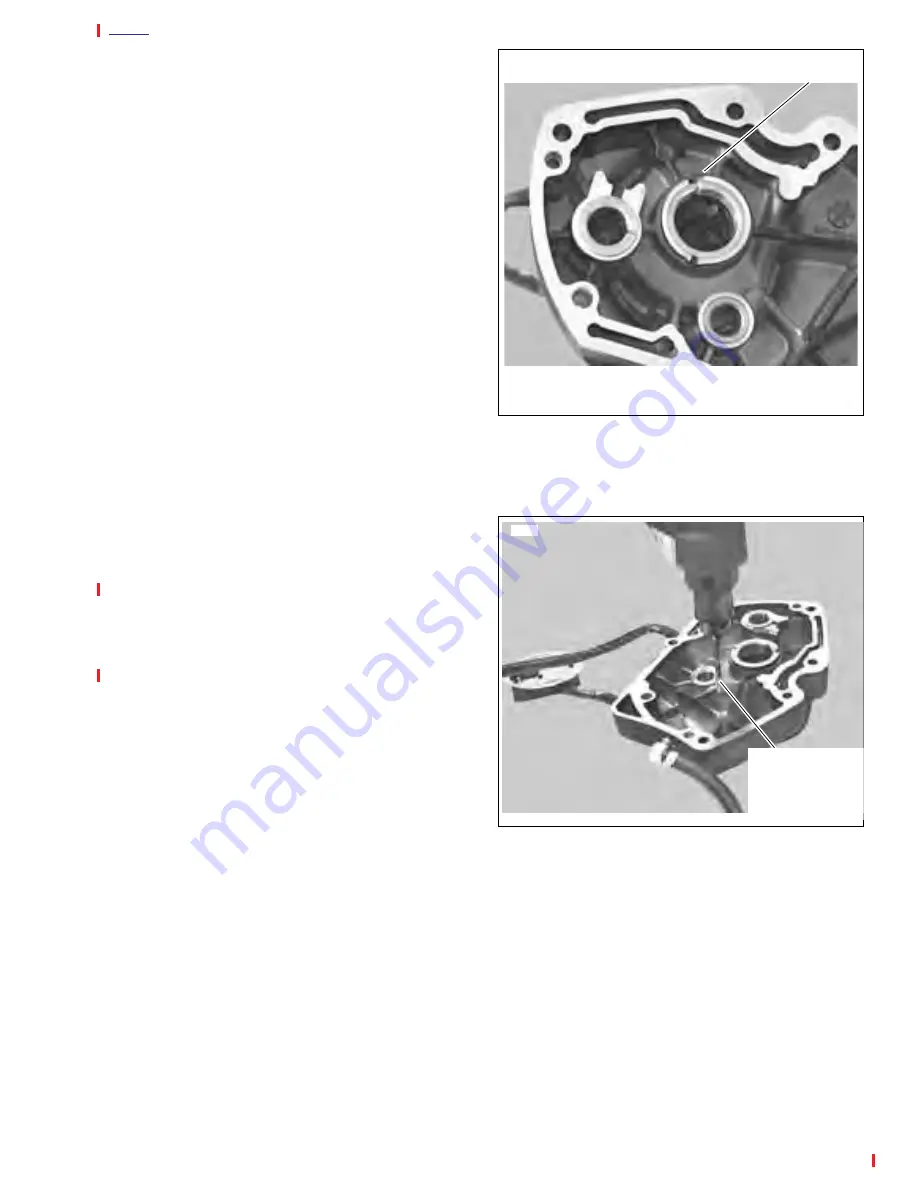

See

Figure 3-105.

Position bushing over bore of gear-

case cover with chamfered edge downward and slot

upward. Align slot in bushing with slot in gearcase cover

boss. Press bushing into cover bore until bushing is flush

with cover boss.

2.

See

Bushing Reaming

. After you install a

new

bushing

in gearcase cover, line-ream the bushing to the correct

size.

PINION SHAFT BUSHING IN GEARCASE COVER

1.

See

Figure 3-98.

Using an arbor press, install pinion

shaft bushing in its gearcase cover so that bushing is

flush with cover boss. There is no need to orient this par-

ticular bushing in any specific position of rotation within

the gearcase cover bore.

2.

Although the original pinion shaft bushing is not “pinned,”

the replacement bushing must be secured, from possible

rotation within the cover bore, by installation of a dowel

pin. See

Figure 3-106.

Drill a No. 31 hole, 0.281 in.

(7.137 mm) deep, at top side of boss (side toward top of

gearcase cover), centering the drill bit on the cover bore

circle (hole is drilled half in bushing OD and half in cover

bore ID).

3.

Drive a

new

dowel pin no more than 0.20 in. (5.08 mm)

below the bushing face. Carefully peen edges of hole to

lock the pin in place.

4.

See

Bushing Reaming

. After you install a

new

bushing

in gearcase cover, line-ream the bushing to the correct

size.

Bushing Reaming

NOTE

●

Installing and reaming crankcase and gearcase cover

bushings may alter the center distances between mating

gears and may result in an increase in gear noise. For

quiet-running gears, the gears should be matched to the

center distances.

●

Bushings in right crankcase half serve as pilots for ream-

ing gearcase cover bushings and must, therefore, be

reamed to size first.

●

After reaming any bushing, check shaft fit in the bushing.

It may be necessary to make a second pass with reamer

to attain proper fit.

Figure 3-105. Rear Intake Cam Gear Bushing

Installed in Gearcase Cover

Figure 3-106. Drilling Dowel Pin Hole

1.

Front Intake Cam Gear Bushing

2.

Gearcase Cover

7684

Slot

7682

Replacement

bushing

requires dowel

pin hole

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...