4-12

2002 Buell P3: Fuel System

HOME

AIR CLEANER

4.3

GENERAL

The air cleaner prevents foreign material from entering the

carburetor and engine, trapping airborne dust and dirt in the

filter element. Service the air cleaner filter element every

10,000 miles (16,000 km), or more often if the motorcycle is

run in a dusty environment. Replace the element every

30,000 miles (48,000 km).

REMOVAL

1.

Release five latches around perimeter of air box cover.

See

Figure 4-10.

2.

Remove single Phillips screw at bottom of air box cover

(7 o’clock position).

3.

Pull cover from air box.

4.

Pull conical shaped filter from air box.

5.

Squeeze wings on spring clamp with pliers and pull PCV

outlet hose from fixed position on allen head screw (gold)

at top of venturi ring. Remove screw with spacer.

6.

Remove remaining two allen head screws to free venturi

ring from carburetor flange.

7.

Remove hex screw at bottom of air box (6 o’clock posi-

tion) to release bracket from crankcase hole.

8.

Moving to left side of vehicle, remove two flange bolts to

release side of air box from triangular shaped bracket.

Do not remove bottom bolt to crankcase. See

Figure 4-

12.

CAUTION

Do not take bolt in and out of the crankcase unless nec-

essary. Since the potential for stripping always exists

during removal and installation, leave the bolt intact to

avoid possible damage to the crankcase.

9.

Returning to the right side of the vehicle, carefully pull

out air box. When partially removed, detach PCV outlet

hose from middle fitting on 3-way connector.

10. Remove gasket from inboard side of air box. Discard

gasket.

CLEANING AND INSPECTION

1.

Thoroughly clean air cleaner cover and backplate.

2.

Replace the filter element if damaged or if filter media

cannot be adequately cleaned.

1

1

WARNING

1

WARNING

Do not use gasoline or solvents to clean the filter ele-

ment. Volatile or flammable cleaning agents may cause

an intake system fire, which could result in death or seri-

ous injury.

3.

Wash the filter element (and hose connections) in warm,

soapy water. To remove soot and carbon, soak element

for 30 minutes in warm water with mild detergent.

1

1

WARNING

1

WARNING

Compressed air can pierce the skin and cause injury.

Never use your hand to check for leaks or to determine

air flow rates. Wear safety glasses to shield your eyes

from flying dirt and debris. Failure to comply could result

in death or serious injury.

4.

Dry the filter element using low pressure compressed air

(32 psi/221 kPa maximum). Rotate the element while

moving air nozzle up and down the element exterior. Do

not rap the element on a hard surface.

5.

Hold the filter element up to a strong light source. The

element can be considered sufficiently clean if light is

uniformly visible through the media.

6.

Inspect all hose connections for cuts, tears, holes or

signs of deterioration. Replace as necessary. Direct

compressed air through hoses to verify that they are not

plugged.

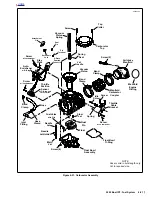

Figure 4-10. Release Air Box Cover Latches

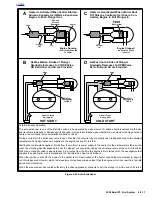

Figure 4-11. Remove Air Box From Bracket

7760

Air Box

Cover

Latch

Flange

Bolt

7757

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...