2002 Buell P3: Drive/Transmission

6-15

HOME

REMOVAL/DISASSEMBLY

Clutch Pack

1

1

WARNING

1

WARNING

To protect against shock and accidental start-up of vehi-

cle, disconnect the negative battery cable before pro-

ceeding. Inadequate safety precautions could result in

death or serious injury.

1.

Remove primary cover. See

6.2 PRIMARY CHAIN

.

1

1

WARNING

1

WARNING

Do not attempt to disassemble the clutch without

SPRING COMPRESSING TOOL (Part No. HD-38515-A),

CLUTCH SPRING FORCING SCREW (Part No. HD-38515-

91) and proper eye protection. Otherwise, the highly

compressed diaphragm spring could fly out with great

force which could result in death or serious injury.

2.

See

Figure 6-20.

Attach tools to compress clutch dia-

phragm spring.

a. Thread the CLUTCH SPRING FORCING SCREW

(Part No. HD-38515-91) onto the clutch adjusting

screw.

b.

Place the bridge of SPRING COMPRESSING TOOL

(Part No. HD-38515-A) against diaphragm spring.

c.

Install bearing and washer.

d.

Thread the tool handle onto end of forcing screw.

CAUTION

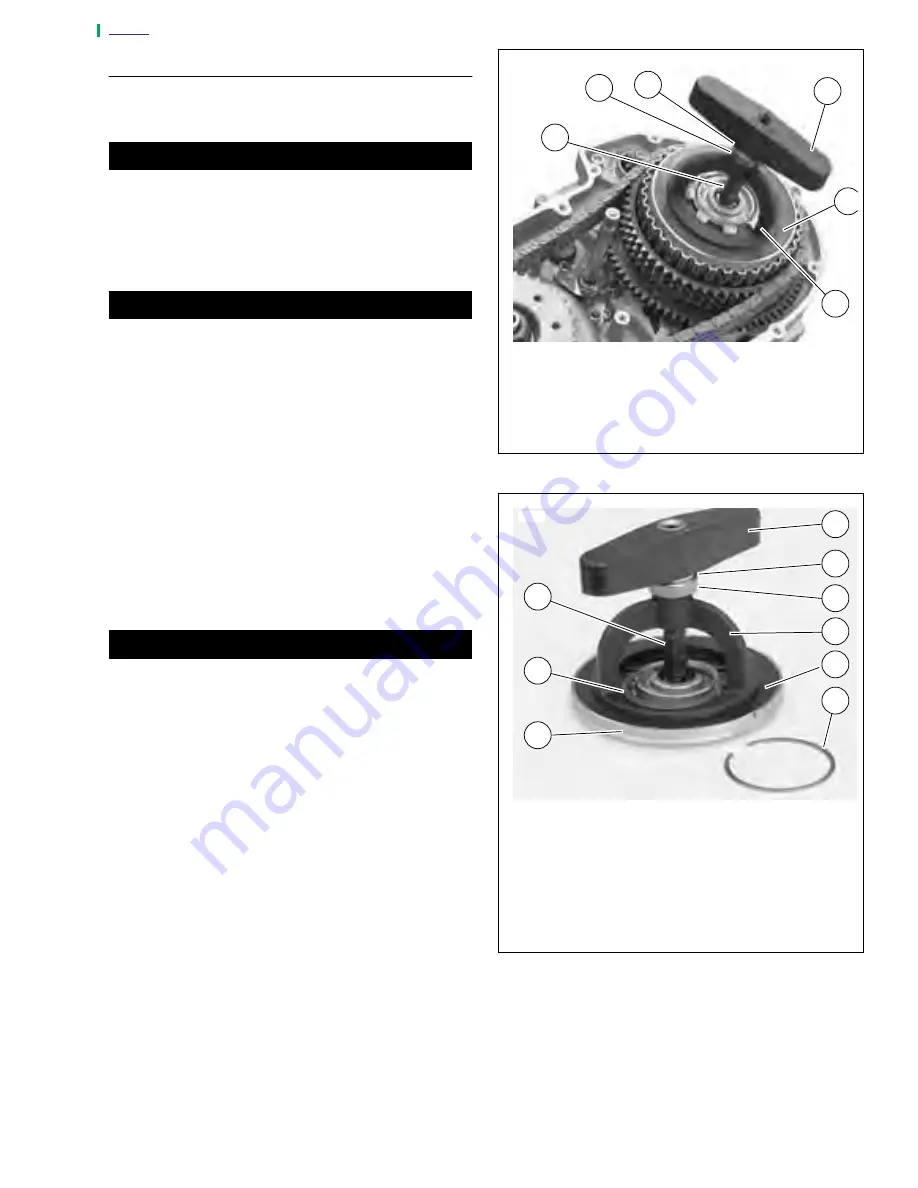

See

Figure 6-21.

Turn compressing tool handle only the

amount required to release spring seat and remove snap

ring. Excessive compression of diaphragm spring could

damage clutch pressure plate.

3.

Remove pressure plate assembly.

a. Place a wrench on the clutch spring forcing screw

flats to prevent the forcing screw from turning.

b.

Turn compressing tool handle clockwise until tool

relieves pressure on snap ring and spring seat.

Remove and discard snap ring.

c. Unseat spring seat from the groove in clutch hub

prongs.

d.

Remove pressure plate assembly.

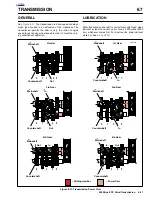

4.

See

Figure 6-23.

Remove the clutch pack from the hub/

shell assembly. The pack consists of five fiber plates and

five steel plates.

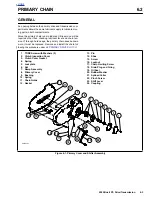

Figure 6-20. Compressing Clutch Diagram Spring

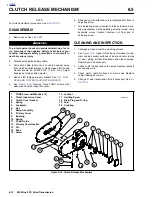

Figure 6-21. Pressure Plate Assembly

7690

1.

Tool Handle

2.

Diaphragm Spring

3.

Bridge

4.

Clutch Spring Forcing Screw

5.

Bearing

6.

Washer

1

6

5

2

4

3

6250

1.

Tool Handle

2.

Washer

3.

Bearing

4.

Bridge

5.

Diaphragm Spring

6.

Snap Ring

7.

Pressure Plate

8.

Spring Seat

1

3

2

9

8

7

4

6

5

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...