2002 Buell P3: Drive/Transmission

6-17

HOME

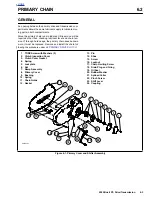

Primary Chain/Drive

1

1

WARNING

1

WARNING

To protect against shock and accidental start-up of vehi-

cle, disconnect the negative battery cable before pro-

ceeding. Inadequate safety precautions could result in

death or serious injury.

1.

Remove negative battery cable from battery.

2.

Remove primary cover. See

6.2 PRIMARY CHAIN

.

3.

Loosen engine sprocket.

a. Install SPROCKET LOCKING LINK (Part No. HD-

38362).

b.

Remove the engine sprocket nut.

c.

Loosen, but do not remove, engine sprocket. If nec-

essary, use the slotted portion of

TWO CLAW

PULLER (Part No. HD-97292-61) and two bolts to

loosen the engine sprocket.

4.

See

Figure 6-23.

Remove adjusting screw assembly.

a.

Remove large retaining ring.

b.

Remove adjusting screw assembly from pressure

plate.

CAUTION

See

Figure 6-24.

Mainshaft nut has left-hand threads. To

prevent damage, turn nut clockwise to loosen and

remove from mainshaft.

5.

Remove mainshaft nut and washer.

6.

Remove the clutch assembly, primary chain and engine

sprocket as a unit.

a. Inspect primary chain and sprockets for damage or

excessive wear.

b.

Inspect stator and rotor. See

7.14 ALTERNATOR.

c.

Replace damaged parts as necessary.

7.

Install adjusting screw assembly into pressure plate.

a. See

Figure 6-24.

Align two tabs on perimeter of

release plate with corresponding recesses in pres-

sure plate.

b.

See

Figure 6-23.

Secure the adjusting screw

assembly with large retaining ring.

8.

Attach tools to compress clutch diaphragm spring. See

Step 2 of

CLUTCH PACK

under

6.6 PRIMARY DRIVE/

CLUTCH.

9.

Remove clutch pack components. See Steps 3-4 of

CLUTCH PACK

under

6.6 PRIMARY DRIVE/CLUTCH.

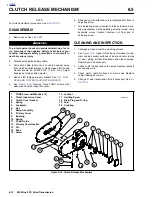

10. See

Figure 6-21.

Disassemble pressure plate.

a. Place a wrench on the clutch spring forcing screw

flats to prevent the forcing screw from turning.

b.

Turn the compressing tool handle counterclockwise

until the handle spins off.

c.

Remove washer, bearing and bridge.

d. Remove clutch spring forcing screw from clutch

adjusting screw.

e.

Remove spring seat and diaphragm spring from

pressure plate.

11. See

Figure 6-23.

Remove and disassemble adjusting

screw assembly.

a.

Remove large retaining ring.

b.

Remove adjusting screw assembly from pressure

plate.

c. If necessary, disassemble adjusting screw assem-

bly. Remove and discard small retaining ring and

then separate the adjusting screw from the bearing

and release plate. Remove bearing from release

plate.

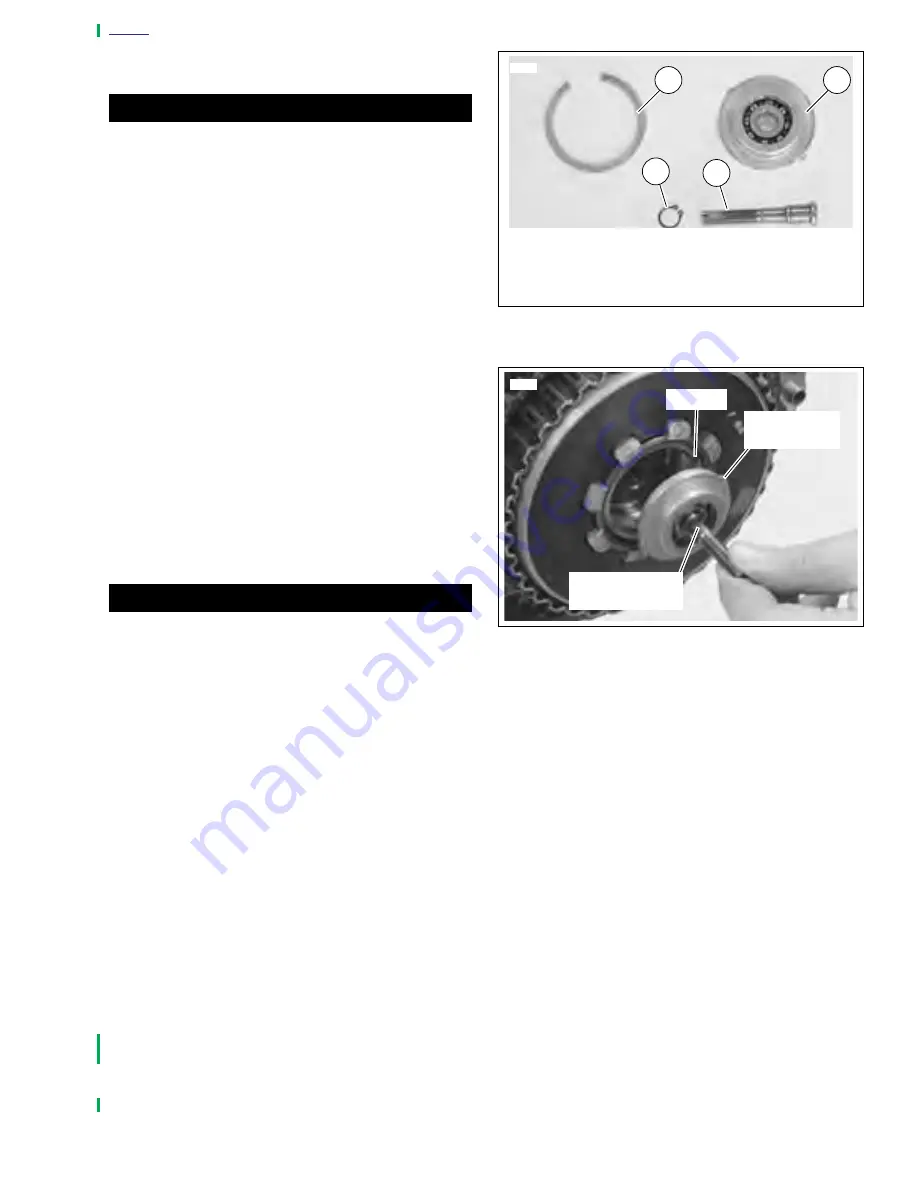

Figure 6-23. Adjusting Screw Assembly

Figure 6-24. Aligning Tabs

6251

1

1.

Retaining Ring

2.

Bearing and Release Plate

3.

Retaining Ring

4.

Adjusting Screw

2

3

4

6141

Tab on

release plate

Recess

Adjusting

screw assembly

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...