6-18

2002 Buell P3: Drive/Transmission

HOME

CAUTION

See

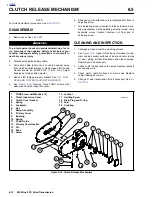

Figure 6-22.

To prevent possible damage to the bear-

ing, the clutch hub and shell assembly should not be dis-

assembled unless the bearing, hub or shell require

replacement. If the assembly is pressed apart, the bear-

ing must be replaced.

12. Disassemble clutch hub and clutch shell if necessary.

a. Remove retaining ring from inboard end of clutch

hub.

b.

Using an arbor press, separate clutch hub from

assembly of clutch shell, bearing and retaining ring.

c.

Remove retaining ring from groove in clutch shell.

d. Press on the inboard side of bearing outer race to

remove bearing from clutch shell.

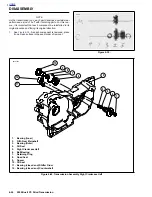

INSPECTION

1.

Wash all parts, except fiber (friction) plates and bearing,

in cleaning solvent. Blow dry with compressed air. Exam-

ine the clutch components as follows:

a.

Check all clutch plates for wear and discoloration.

b.

Inspect each steel (drive) plate for grooves.

c. Place each steel plate on a flat surface. Using a

feeler gauge, check for flatness in several places.

Replace any plates that are damaged or are warped

more than 0.006 in. (0.152 mm).

2.

Check the diaphragm spring for cracks or bent tabs.

Install a

new

spring if either condition exists.

3.

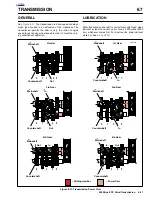

See

Figure 6-25.

Check fiber plates for thickness.

a. Wipe the lubricant from the five fiber plates and

stack them on top of each other.

b.

Measure the thickness of the five stacked fiber

plates with a dial caliper or micrometer. The mini-

mum thickness must be 0.413 in. (10.490 mm).

c. If the thickness is less than specified, discard the

fiber plates and steel plates. Install a

new

set of

both friction and steel plates.

4.

See

Figure 6-26.

Check the clutch shell.

a. Inspect primary chain sprocket and the starter ring

gear on the clutch shell. If either sprocket or ring

gear are badly worn or damaged, replace the clutch

shell.

b. Check the slots that mate with the clutch plates on

both clutch shell and hub. If slots are worn or dam-

aged, replace shell and/or hub.

c.

If clutch shell was removed from motorcycle, check

the bearing for smoothness. Rotate the clutch shell

while holding the clutch hub. If bearing is rough or

binds, it must be replaced.

Figure 6-25. Measuring Friction Plates

Figure 6-26. Checking Clutch Shell

7738

6252

2

1

3

4

1.

Primary Chain Sprocket

2.

Starter Ring Gear

3.

Slots on Clutch Hub

4.

Slots on Clutch Shell

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...