2002 Buell P3: Drive/Transmission

6-19

HOME

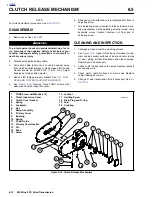

ASSEMBLY

Clutch Pack

See

Figure 6-22.

Install the clutch pack which consists of five

fiber plates and five steel plates, into the clutch hub. The

order of plate assembly, from inboard to outboard, is as fol-

lows:

St - F - St - F - St - F - St - F - St - F

(St = Steel plate, F = Fiber plate)

CAUTION

See

Figure 6-21.

Turn compressing tool handle only the

amount required to install spring seat and snap ring.

Excessive compression of diaphragm spring could dam-

age clutch pressure plate.

5.

Place assembly of spring seat,

new

snap ring, dia-

phragm spring, pressure plate, adjusting screw compo-

nents and compressing tool onto clutch hub and against

clutch pack.

a. See

Figure 6-27.

Align square openings of pressure

plate and diaphragm spring so that the assembly

can be installed over prongs of clutch hub.

b.

Position spring seat with its larger O.D. side toward

diaphragm spring.

c. See

Figure 6-28.

Place a wrench on the clutch

spring forcing screw flats to prevent the forcing

screw from turning.

d. Turn compressing tool handle clockwise until dia-

phragm spring compresses just enough to install

spring seat and

new

snap ring into the groove in

clutch hub prongs.

e.

With snap ring positioned against outboard side of

spring seat, and fully seated in groove of clutch hub,

carefully loosen and remove compression tool.

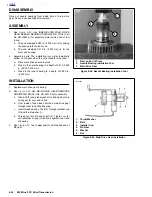

Primary Drive

1.

See

Figure 6-28.

Assemble clutch hub and shell if nec-

essary.

a. Press

new

bearing in clutch shell. Secure bearing

with a

new

retaining ring.

b.

Press inboard end of clutch hub into shell bearing.

Secure with

new

retaining ring on end of hub.

2.

Assemble pressure plate hardware.

a. See

Figure 6-23.

Place bearing inside release plate.

Insert adjusting screw through bearing and release

plate. Secure with

new

retaining ring.

b.

See

Figure 6-27.

Position diaphragm spring with its

concave side facing toward pressure plate onto

pressure plate assembly.

c.

Insert adjusting screw assembly into pressure plate.

Secure with large retaining ring.

d. Position spring seat with its larger O.D. side toward

diaphragm spring.

3.

Attach tools to compress clutch diaphragm spring. Do

not tighten compressing tool against diaphragm spring at

this time. See Step 2 of

CLUTCH PACK

under

6.6 PRI-

MARY DRIVE/CLUTCH

.

4.

Install the clutch pack. Follow all instructions of

CLUTCH

PACK

under

6.6 PRIMARY DRIVE/CLUTCH

.

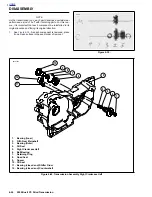

Figure 6-27. Spring Seat Installation

Figure 6-28. Clutch Hub and Shell Assembly

5

6253

1

2

1.

Diaphragm Spring (pressure plate below)

2.

Prongs on Clutch Hub

3.

Retaining Ring

4.

Adjusting Screw Assembly

5.

Spring Seat

4

3

a0115x6x

1.

Clutch Hub

2.

Retaining Ring

3.

Bearing

4.

Clutch Shell

5.

Retaining Ring

1

2

3

4

5

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...