6-24

2002 Buell P3: Drive/Transmission

HOME

TRANSMISSION DISASSEMBLY

6.9

CASE REMOVAL

NOTES

●

If transmission only is being serviced, do not remove fly-

wheel assembly.

●

For crankcase, flywheel or other major servicing, the fly-

wheel assembly can be removed at any time. The same

specialty tools are used.

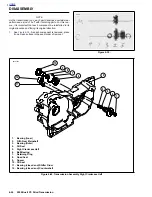

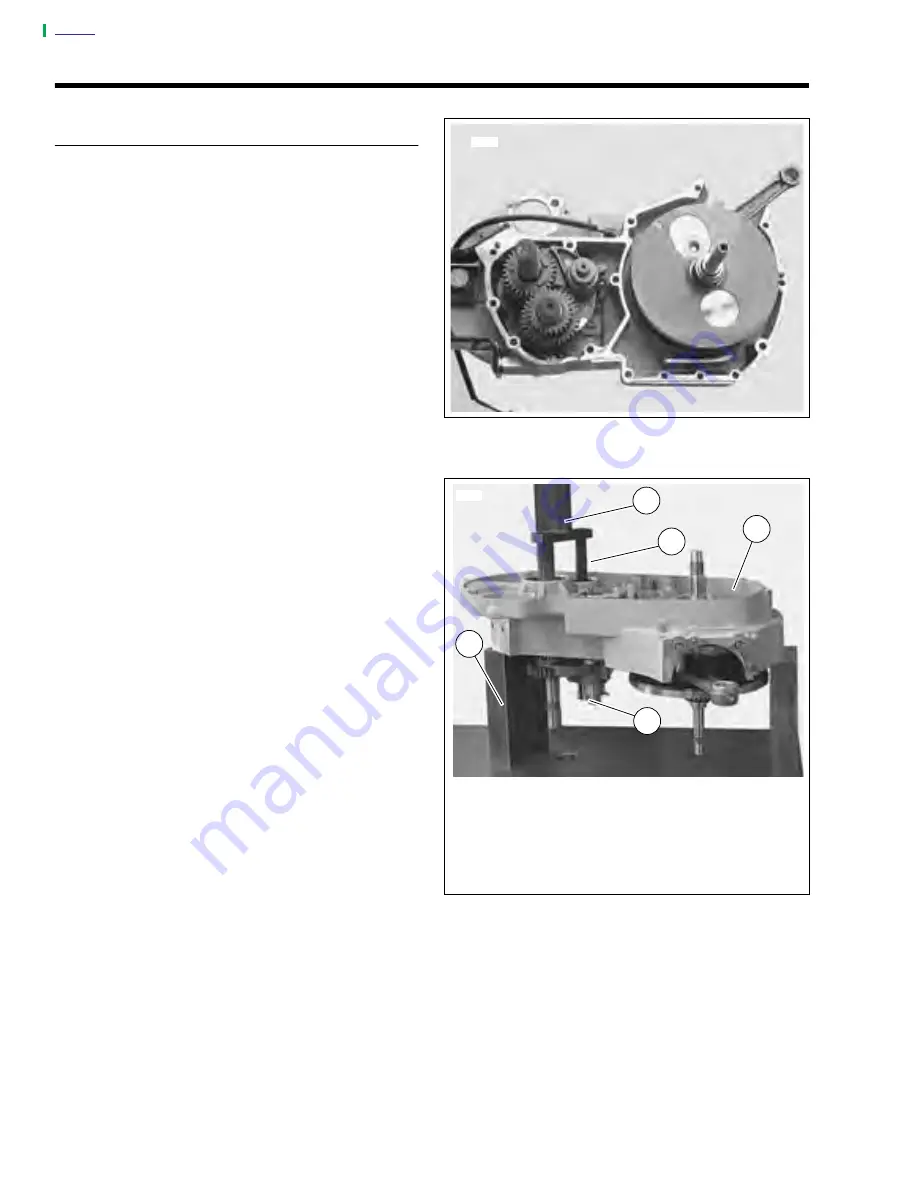

1.

See

Figure 6-36.

Remove transmission case. See

6.8

TRANSMISSION CASE

2.

See

Figure 6-36.

Split crankcases in half. See

6.8

TRANSMISSION CASE

.

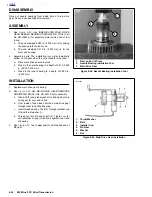

3.

Remove crankcase and transmission assembly from

engine stand.

4.

See

Figure 6-37.

Place crankcase (3) and transmission

assembly (4) into fixture on arbor press (1).

a.

Support transmission assembly on parallel supports

(5).

5.

Press transmission assembly using TRANSMISSION

REMOVER (2) (Part No. B-43895-1) to remove transmis-

sion assembly from crankcase half.

6.

Remove crankcase from fixture.

Figure 6-36. Transmission Assembly

Figure 6-37. Transmission Remover/Installer on Fixture

7693

7737

1.

Arbor Press

2.

Transmission Remover (Part no. B-43985-1)

3.

Crankcase

4.

Transmission Assembly

5.

Parallel Supports

1

4

5

2

3

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...