2002 Buell P3: Drive/Transmission

6-35

HOME

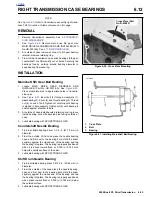

RIGHT TRANSMISSION CASE BEARINGS

6.12

NOTE

See

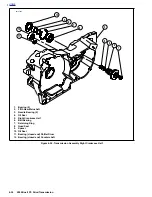

Figure 6-52.

Refer to Transmission assembly right crank-

case half, for location of items discussed on this page.

REMOVAL

1.

Remove transmission assembly. See

6.9 TRANSMIS-

SION DISASSEMBLY

.

2.

See

Figure 6-50.

Remove main drive 5th gear. Use

MAIN DRIVE GEAR REMOVER AND INSTALLER (Part

No.HD-35316A). See

6.11 MAIN DRIVE GEAR

.

3.

At outside of case remove seal next to 5th gear bearing

retainer. Remove retaining ring.

4.

From inside transmission case drive bearings (5th gear,

countershaft or shifter shaft) out of bores. Carefully tap

bearings free by working around bearing diameter to

keep bearing from skewing.

INSTALLATION

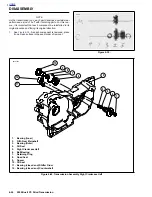

Mainshaft 5th Gear Ball Bearing

1.

Locate MAIN DRIVE GEAR REMOVER AND

INSTALLER (Part No. HD-35316-A). See

Figure 6-50.

Place crossplate pins in appropriate holes in transmis-

sion case.

2.

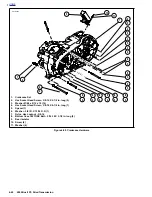

See

Figure 6-51.

Insert bolt (2) through crossplate (1),

new

bearing (3), driver (4) and thrust bearing (5). Thread

nut (6) on end of bolt. Tighten nut carefully until bearing

is started in bore squarely. Tighten nut (6) until bearing is

seated against shoulder in bore.

3.

At outside of case install beveled retaining ring in groove

inside bearing bore with beveled side facing outside of

case.

4.

Lubricate bearing with SPORT-TRANS FLUID.

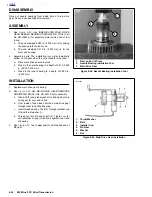

Countershaft Needle Bearing

1.

Find a suitable bearing driver 1-1/4 in. (31.75 mm) in

diameter.

2.

From the outside of the case place the needle bearing

open end first next to the bearing bore. Hold the driver

squarely against the closed end of the bearing and tap

the bearing into place. The bearing is properly positioned

when it is driven inward flush or 0.030 in. (0.762 mm)

below the outside surface of the case.

3.

Lubricate bearing with SPORT-TRANS FLUID.

Shift Drum Needle Bearing

1.

Find a suitable bearing driver 0.8125 in. (20.64 mm) in

diameter.

2.

From the outside of the case place the needle bearing,

open end first, next to the bearing bore. Hold the driver

squarely against the closed end of the bearing and tap

the bearing into place. The bearing is properly positioned

when driven inward flush or 0.030 in. (0.762 mm) below

the outside surface.

3.

Lubricate bearing with SPORT-TRANS FLUID.

Figure 6-50. Cross Plate Mounting

Figure 6-51. Installing Mainshaft Ball Bearing

Cross Plate (Part

No. B-43983)

7397

1.

Cross Plate

2.

Bolt

3.

Bearing

a0125xSX

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...