6-44

2002 Buell P3: Drive/Transmission

HOME

4.

If you cannot align lockplate and sprocket screw holes,

nut may be additionally tightened until screw holes align.

5.

See

Figure 6-63.

Install two socket head screws through

aligned holes of lockplate and into tapped holes of

sprocket. Tighten to 90-110

in-lbs

(10-12 Nm).

NOTE

The original equipment socket head screws (5) have thread-

locking compound applied to them. Since this compound

remains effective for about three removal/installation cycles,

the original screws may be reused up to three times. After the

third removal/installation cycle, replace both screws with

new

screws identical to the original.

6.

Install the remaining removed components in the reverse

order of the removal procedures. See the procedures

listed in the respective component sections.

7.

Fill transmission to proper level with fresh lubricant. See

6.4 CLUTCH

.

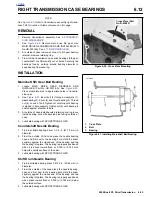

Figure 6-65. Transmission Sprocket Tightening

Figure 6-66. Aligning Transmission Sprocket

7399

2

1.

Sprocket Holding Tool (Part No. B-43982)

2.

Mainshaft Locknut Wrench

(Part No. HD-94660-37B)

1

45°

30°

Transmission

Sprocket

Transmission

Sprocket Nut

Line scribed on nut and sprocket

a0163x6x

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...