2-24

2002 Buell P3: Chassis

HOME

FRONT BRAKE CALIPER

2.11

REMOVAL

NOTE

Steps 1 and 2 are not required for detaching caliper from

rotor. Drain fluid only when disassembling caliper.

1.

Drain and discard brake fluid.

CAUTION

Damaged banjo bolt seating surfaces will leak when

reassembled. Prevent damage to seating surfaces by

carefully removing brake line components.

2.

See

Figure 2-36.

Remove banjo bolt (2) (metric) and two

banjo washers (3) to disconnect brake line (1) from cali-

per. Discard banjo washers.

3.

Remove brake pads.

a.

Remove pin plug (4).

b.

See

Figure 2-37.

Remove pad hanger pin (1) (met-

ric).

c.

Remove brake pads from caliper.

4.

See

Figure 2-36.

Detach caliper from mounts.

a.

Remove lower mounting screw (5).

b.

Remove upper mounting screw (5) and brake line

wireform (7) while supporting caliper above brake

rotor.

c. Slowly remove caliper by tilting away from wheel

and then pulling away from rotor.

d.

Separate carrier and caliper.

DISASSEMBLY

1.

See

Figure 2-38.

Use BRAKE CALIPER PISTON

REMOVER (Part No. B-42887) to pull the two pistons

from caliper bores.

2.

See

Figure 2-39.

Remove piston outer seals (4) and

inner seals (2) from their respective grooves in caliper.

Discard seals.

3.

Check bleeder valve (metric). Remove and replace if

damaged.

CLEANING AND INSPECTION

1

1

WARNING

1

WARNING

Clean brake system components using denatured alco-

hol. Do not use mineral-base cleaning solvents, such as

gasoline or paint thinner. Use of mineral-base solvents

causes deterioration of rubber parts that continues after

assembly. This could result in improper brake operation

which could result in death or serious injury.

1.

Clean all parts with denatured alcohol or

D.O.T. 4

BRAKE FLUID

. Do not contaminate with mineral oil or

other solvents. Wipe dry with a clean, lint free cloth. Blow

out drilled passages and bore with a clean air supply. Do

not use a wire or similar instrument to clean drilled pas-

sages.

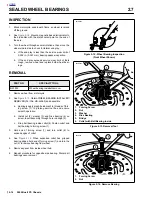

Figure 2-36. Front Brake Caliper

5

2

1

3

4

1.

Brake Line

2.

Banjo Bolt (metric)

3.

Banjo Washers (2)

4.

Pin Plug

5.

Mounting Screws (2)

6.

Bleeder Valve

7.

Wireform

8273

6

7

Summary of Contents for 2002 P3

Page 2: ......

Page 17: ...A 15 Appendix A Tools HOME ...

Page 32: ...C 3 Appendix C Metric Conversions HOME ...

Page 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Page 75: ......

Page 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Page 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Page 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Page 146: ......

Page 147: ......

Page 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Page 225: ......

Page 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Page 258: ......

Page 259: ......

Page 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Page 281: ......

Page 327: ......

Page 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Page 400: ...Product 1 2 ...