1-26

2003 Buell XB9S: Maintenance

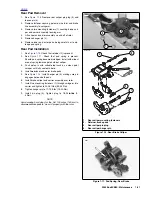

DRIVE BELT

1.10

GENERAL

The drive belt tension on a new belt will be considerably tight

and will loosen after approximately 1000 miles (1600 km).

The drive belt tension is automatically maintained] by the idler

pulley. Axle alignment is not adjustable.

Check drive belt and idler pulley condition:

●

At the 1000 mile (1600 km) service interval.

●

At every 5000 mile (8000 km) service interval.

Replace drive belt and idler pulley assembly:

●

At every 15,000 mile (24,000 km) service interval.

INSPECTION

Rear Sprocket

NOTE

If chrome chips or gouges to rear sprocket are large enough

to be harmful, they will leave a pattern on the belt face.

1.

Inspect each tooth of rear sprocket for:

a.

Major tooth damage.

b.

Large chrome chips with sharp edges.

c.

Gouges caused by hard objects.

d.

Excessive loss of chrome plating (see Step 2).

2.

To check if chrome plating has worn off, drag a scribe or

sharp knife point across the bottom of a groove (2)

(between two teeth) with medium pressure.

a. If scribe or knife point slides across groove without

digging in or leaving a visible mark, chrome plating

is still good.

b.

If scribe or knife point digs in and leaves a visible

mark, it is cutting the bare aluminum. A knife point

will not penetrate the chrome plating.

3.

Replace rear sprocket if major tooth damage or loss of

chrome exists.

Drive Belt

Inspect drive belt for:

●

Cuts or unusual wear patterns on both sides of belt.

●

Outside edge bevelling (8). Some bevelling is common,

but it indicates that sprockets are misaligned.

●

Outside surface for signs of stone puncture (7). If cracks/

damage exists near edge of belt, replace belt immedi-

ately. Damage to center of belt will require belt replace-

ment eventually, but when cracks extend to edge of belt,

belt failure is imminent.

●

Inside (toothed portion) of belt for exposed tensile cords

(normally covered by nylon layer and polyethylene layer).

This condition will result in belt failure and indicates worn

transmission sprocket teeth. Replace belt and transmis-

sion sprocket.

●

Signs of puncture or cracking at the base of the belt

teeth. Replace belt if either condition exists.

Idler Pulley

Inspect idler pulley for signs of uneven wear. Excessive play

or roughness indicates worn bearings. Replace idler pulley as

an assembly. See following section.

CLEANING

Keep dirt, grease, oil, and debris off the belt, idler pulley and

sprockets. Clean the drive belt with a mild soap and water

spray solution as required. Dry thoroughly. Do not immerse

belt in solution.