2-28

2004 Buell Lightning: Chassis

HOME

INSTALLATION

1.

See

Figure 2-37.

Install front brake lamp switch (11).

a. Install brake lamp switch (11) with switch fastener

(10) and tighten to 7-10 in-lbs (0.8-1.0 Nm).

b.

Connect brake switch terminal (12) to brake lamp

switch (11).

c. Test switch action. Tang on switch must release

when hand lever is moved.

2.

Install master cylinder to handlebar by fastening clamp

with fasteners. Position for rider posture and tighten to

80-90 in-lbs (9-10 Nm).

1

1

WARNING

1

WARNING

Use only copper crush banjo washers (See Parts Catalog

for Part No.) with D.O.T. 4 brake fluid. Earlier silver banjo

washers are not compatible with D.O.T. 4 fluid and will

not seal properly over time. Failure to comply may

adversely affect braking ability and lead to brake failure

which could result in death or serious injury.

1

1

WARNING

1

WARNING

To avoid leakage, verify that banjo washers, banjo bolt,

hydraulic brake line and master cylinder bore are com-

pletely clean.

3.

See

Figure 2-37.

Connect brake line to master cylinder

using two new copper washers (15) and banjo bolt (13)

(metric) and tighten to 16-20 ft-lbs (22-27 Nm).

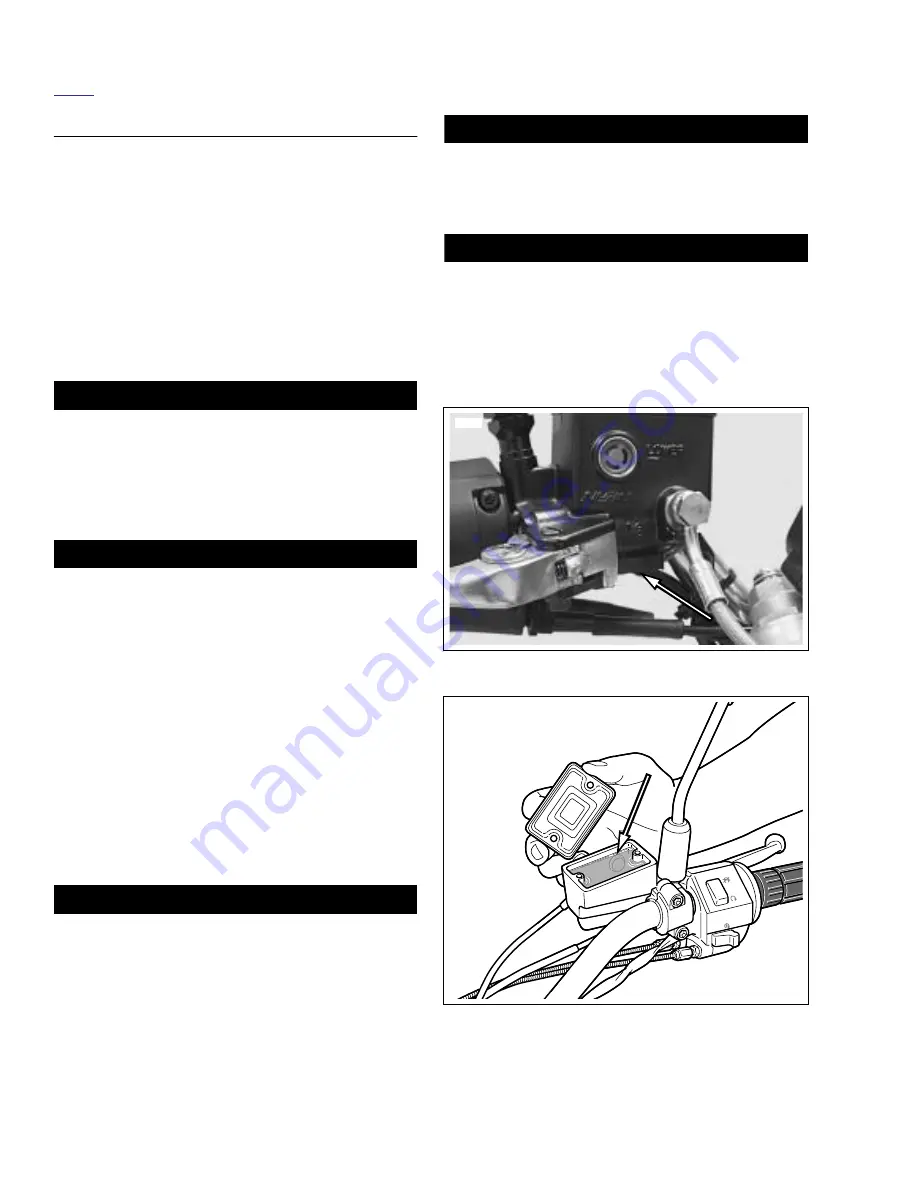

4.

See

Figure 2-40.

Verify brake lamp switch wires are tight.

5.

See

Figure 2-37.

Remove two master cylinder cover

screws (1), cover (2) and cover gasket (3).

6.

Protect body work from brake fluid.

7.

See

Figure 2-41.

With the master cylinder in a level posi-

tion, add D.O.T. 4 BRAKE FLUID. Bring fluid level to

within 1/8 in. (3.2 mm) of molded boss inside front mas-

ter cylinder reservoir.

1

1

WARNING

1

WARNING

Verify proper operation of the master cylinder relief port.

A plugged or covered relief port can cause brake drag or

lockup, which could result in loss of vehicle control

which could result in death or serious injury.

8.

Verify proper operation of the master cylinder relief port.

Actuate the brake lever with the reservoir cover removed.

A slight spurt of fluid will break the surface if all internal

components are working properly.

9.

Bleed brake system. See

1.7 BRAKE SYSTEM MAINTE-

NANCE.

10. See

Figure 2-37.

Attach master cylinder cover (2) and

cover gasket (3). Tighten two cover fasteners (1) to 9-

13 in-lbs (1.0-1.5 Nm).

11. Pump lever to raise pressure to operating level.

1

1

WARNING

1

WARNING

Always test motorcycle brakes at low speed after servic-

ing or bleeding system. To prevent death or serious

injury, Buell recommends that all brake repairs be per-

formed by a Buell dealer or other qualified technician.

1

1

WARNING

1

WARNING

Check for proper brake lamp operation before riding

motorcycle. Visibility is a major concern for motorcy-

clists. Failure to have proper brake lamp operation could

result in death or serious injury.

12. Turn ignition key switch to ON. Apply brake hand lever to

test brake lamp operation. Turn ignition key switch to

OFF.

Figure 2-40. Front Brake Light Switch Connector

Figure 2-41. Brake Fluid Level

(Standard Brake Reservoir Shown)

8923

b0613x2x

Summary of Contents for 2004 XB9S

Page 2: ......

Page 35: ...D 2 2004 Buell Lightning Appendix D HOME Rear Brake Systems Top View b1115xbsx ...

Page 36: ...2004 Buell Lightning Appendix D D 3 HOME Rear Brake Systems Left Side View b1116xcsx ...

Page 44: ...2004 Buell Lightning Appendix D D 11 HOME Clutch Cable Right Side View b1124xasx ...

Page 47: ...HOME NOTES ...

Page 49: ......

Page 103: ......

Page 201: ...HOME NOTES ...

Page 203: ......

Page 275: ...HOME NOTES ...

Page 307: ...HOME NOTES ...

Page 311: ...HOME NOTES ...

Page 351: ...HOME NOTES ...

Page 441: ......

Page 463: ...HOME NOTES ...

Page 465: ......

Page 517: ...HOME NOTES ...

Page 519: ......

Page 595: ...HOME NOTES ...

Page 597: ......