2004 Buell Lightning: Fuel System

4-99

HOME

IGNITION COIL

4.32

TROUBLESHOOTING

Follow the troubleshooting procedures listed under

4.8 INI-

TIAL DIAGNOSTIC CHECK

if the engine will not start, is diffi-

cult to start or runs roughly. Also check condition of spark

plug cables. Insulation on cables may be cracked or damaged

allowing high tension current to short to metal parts. This

problem is most noticeable when cables are wet.

If poor starting/running condition persists, check resistance of

ignition coil primary and secondary windings using an ohm-

meter.

Ignition Coil Primary Circuit Test

1.

Remove ignition coil. See

REMOVAL

in this section.

2.

Set ohmmeter scale to RX1.

3.

See

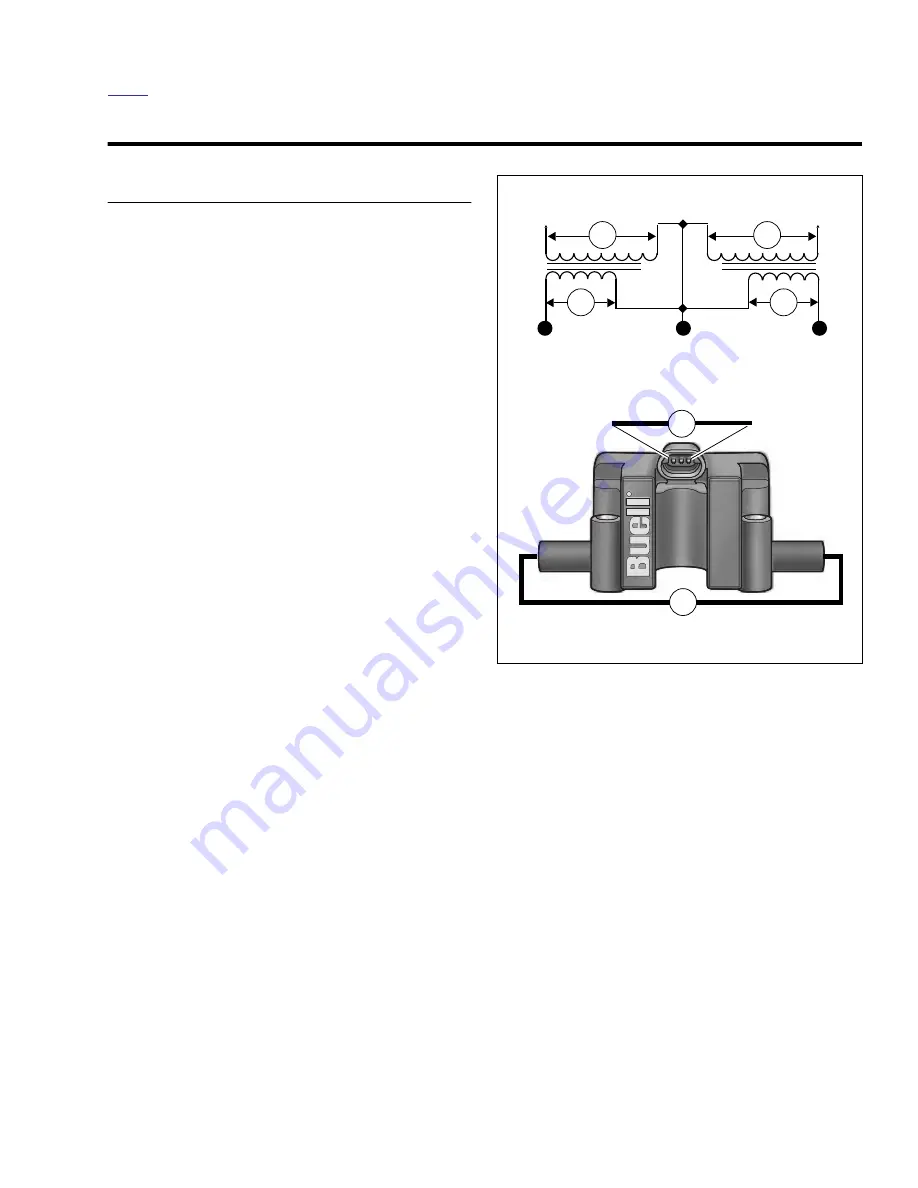

Figure 4-69.

Place multimeter wires on primary coil

windings (1).

4.

Check for primary coil winding resistance.

a.

Normal resistance range is 0.5-0.7 ohms.

b. See

TEST RESULTS

if resistance is not within nor-

mal operating range.

Ignition Coil Secondary Circuit Test

1.

Remove ignition coil. See

4.32 IGNITION COIL

.

2.

Set ohmmeter scale to RX1K.

3.

See

Figure 4-69.

Place multimeter wires on secondary

coil windings (2).

4.

Check for secondary coil winding resistance.

a.

Normal resistance range is 5.5-7.5K ohms.

b. See

TEST RESULTS

if resistance is not within nor-

mal operating range.

Test Results

1.

A low resistance value indicates a short in the coil wind-

ing. Replace coil.

2.

A high resistance value might indicate that there is some

corrosion/oxidation of the coil terminals. Clean the termi-

nals and repeat resistance test. If resistance is still high

after cleaning terminals, replace coil.

3.

An infinite ohms (

∞

or no continuity) resistance value

indicates an open circuit (a break in the coil winding).

Replace coil.

Ignition Coil Substitution

If a coil tester is not available, use the following test.

NOTE

Coil will function without being attached to frame.

1.

Substitute a

new

ignition coil by attaching it to any con-

venient point near the old coil. Transfer terminal wires to

new

coil.

2.

Attach

new

spark plug cables to coil and plugs.

3.

Test system. If ignition trouble is eliminated by the tem-

porary installation of a

new

coil, carefully inspect old coil

and cables for damage. The insulation on the cables may

be cracked or otherwise damaged allowing high tension

current to short to metal parts. This is most noticeable in

wet weather or after the motorcycle has been washed.

Figure 4-69. Ignition Coil Testing

2

b0675x7x

2

1

1

Terminal B

+12 V

Terminal C

(front coil)

Terminal A

(rear coil)

1.

Primary Resistance should be 0.5-0.7 ohms.

2.

Secondary Resistance should be 5.5-7.5K ohms.

2

b0993x4x

1

Summary of Contents for 2004 XB9S

Page 2: ......

Page 35: ...D 2 2004 Buell Lightning Appendix D HOME Rear Brake Systems Top View b1115xbsx ...

Page 36: ...2004 Buell Lightning Appendix D D 3 HOME Rear Brake Systems Left Side View b1116xcsx ...

Page 44: ...2004 Buell Lightning Appendix D D 11 HOME Clutch Cable Right Side View b1124xasx ...

Page 47: ...HOME NOTES ...

Page 49: ......

Page 103: ......

Page 201: ...HOME NOTES ...

Page 203: ......

Page 275: ...HOME NOTES ...

Page 307: ...HOME NOTES ...

Page 311: ...HOME NOTES ...

Page 351: ...HOME NOTES ...

Page 441: ......

Page 463: ...HOME NOTES ...

Page 465: ......

Page 517: ...HOME NOTES ...

Page 519: ......

Page 595: ...HOME NOTES ...

Page 597: ......