3-20

2007 Buell Ulysses: Engine

HOME

12. Disconnect and remove air scoops, right and left sides.

See

2.40 AIR SCOOPS

.

13. Remove chin fairing. See

2.38 CHIN FAIRING

.

14. Remove rear belt and idler pulley. See

6.6 DRIVE BELT

SYSTEM

.

15. Remove transmission sprocket. See

6.16 TRANSMIS-

SION SPROCKET

.

NOTE

For details on the interactive exhaust system, see

7.6 INTER-

ACTIVE EXHAUST SYSTEM.

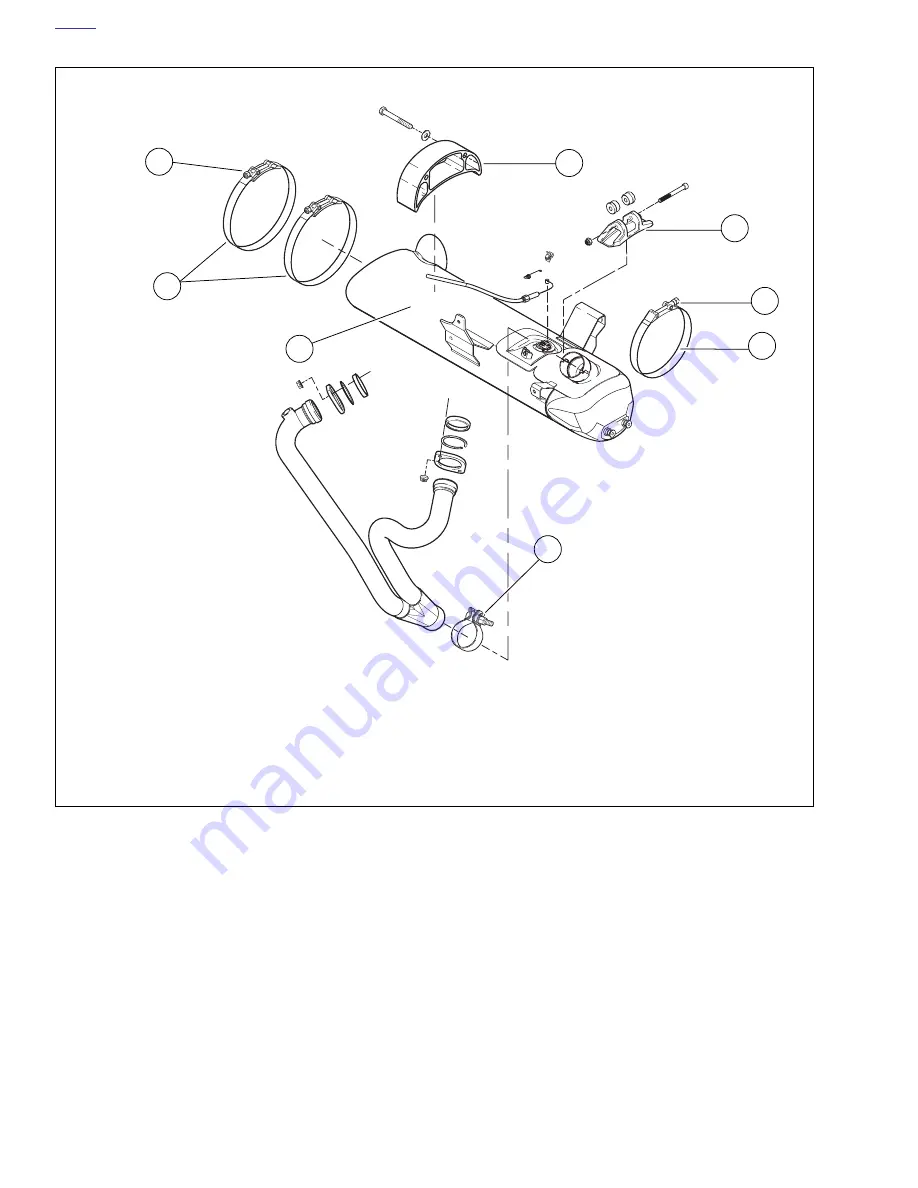

16. See

Figure 3-15.

Remove muffler. See

2.32 EXHAUST

SYSTEM

.

Figure 3-15. Muffler and Mounting System

b0986x3c

1.

Clamp, Torca

2.

Muffler

3.

Muffler strap, front

4.

Front muffler strap fastener

5.

Front muffler mount

6.

Rear muffler bracket

7.

Rear muffler strap fastener

8.

Muffler strap, rear (2)

1

4

6

5

2

3

7

8

Summary of Contents for 2007 ULYSSES

Page 17: ...A 16 2007 Buell Ulysses Appendix A HOME NOTES ...

Page 51: ...D 2 2007 Buell Ulysses Appendix D HOME Figure D 2 Rear Brake Systems Top View b1115acsxu ...

Page 63: ...D 14 2007 Buell Ulysses Appendix D HOME NOTES ...

Page 73: ......

Page 103: ...1 30 2007 Buell Ulysses Maintenance HOME NOTES ...

Page 129: ......

Page 237: ...2 108 2007 Buell Ulysses Chassis HOME NOTES ...

Page 239: ......

Page 309: ...3 70 2007 Buell Ulysses Engine HOME NOTES ...

Page 347: ...3 108 2007 Buell Ulysses Engine HOME NOTES ...

Page 391: ...4 42 2007 Buell Ulysses Fuel System HOME NOTES ...

Page 481: ......

Page 505: ......

Page 561: ...6 56 2007 Buell Ulysses Drive Transmission HOME NOTES ...

Page 563: ......

Page 587: ...7 24 2007 Buell Ulysses Electrical HOME NOTES ...

Page 645: ...7 82 2007 Buell Ulysses Electrical HOME NOTES ...

Page 647: ......