2003 Buell XB9R: Chassis

2-23

HOME

FRONT BRAKE MASTER CYLINDER AND HAND LEVER 2.10

REMOVAL

NOTE

Steps 1 is not required for removing the master cylinder

assembly from the handlebars. Do not disassemble master

cylinder unless problems are experienced.

1.

Drain brake fluid into a suitable container. Discard used

fluid according to local laws.

a. Install a length of plastic tubing over caliper bleeder

valve. Place free end in a suitable container.

b.

Open bleeder valve (metric) about 1/2-turn.

c.

Pump brake hand lever to drain brake fluid.

d.

Tighten bleeder valve to 36-60 in-lbs (4-7 Nm).

CAUTION

Damaged banjo bolt seating surfaces will leak when

reassembled. Prevent damage to seating surfaces by

carefully removing brake line components.

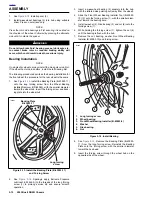

2.

See

Figure 2-35.

Remove the banjo bolt (12) (metric)

and two copper washers (14) to disconnect brake line

(13) from master cylinder (4). Discard copper washers.

3.

Unplug terminal (11) to detach brake lamp switch (10).

NOTE

The individual parts of the brake lamp switch are not service-

able. Replace switch upon failure.

4.

Remove mounting clamp fasteners (5) (metric) to detach

master cylinder reservoir (4) from handlebar.

DISASSEMBLY

Brake Hand Lever

1.

See

Figure 2-35.

Remove pivot bolt nut (8) (metric) and

pivot bolt (15) from hand lever pivot.

2.

Detach front brake hand lever assembly (7) from hand

lever pivot.

3.

Detach front brake lamp switch (10) by removing the

switch fastener (9).

Front Master Cylinder

1.

See

Figure 2-35.

Remove master cylinder cover (2) by

removing cylinder cover fasteners (1).

2.

Discard excess brake fluid.

3.

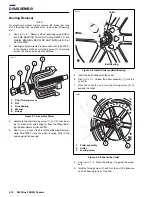

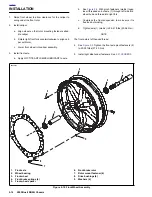

See

Figure 2-34.

Remove rubber boot (1) and discard.

4.

See

Figure 2-33.

Depress piston assembly (1) and

remove internal snap ring (2) and discard.

5.

See

Figure 2-35.

Remove piston assembly (6) from front

master cylinder reservoir (4) and discard.

CLEANING AND INSPECTION

1

1

WARNING

1

WARNING

Clean brake system components using denatured alco-

hol. Do not use mineral-base cleaning solvents, such as

gasoline or paint thinner. Use of mineral-base solvents

causes deterioration of rubber parts that continues after

assembly. This may result in improper brake operation

which could result in death or serious injury.

1.

Clean all parts with denatured alcohol or D.O.T. 4

BRAKE FLUID. Do not contaminate with mineral oil or

other solvents. Wipe dry with a clean, lint free cloth. Blow

out drilled passages and bore with a clean air supply. Do

not use a wire or similar instrument to clean drilled pas-

sages in bottom of reservoir.

2.

Inspect piston bore in master cylinder housing for scor-

ing, pitting or corrosion. Replace housing if any of these

conditions are found.

3.

Inspect outlet port that mates with brake line fitting. As a

critical sealing surface, replace housing if any scratches,

dents or other damage is noted.

Figure 2-33. Piston Assembly in Master Cylinder

8424

2

1.

Piston assembly

2.

Snap ring

1

Summary of Contents for XB9R 2003

Page 2: ...1 2 Edit Me Printed June 5 2002 12 26 pm ...

Page 35: ...D 2 2003 Buell XB9R Appendix D HOME Figure D 2 Rear Brake Systems Top View b1115xbx ...

Page 36: ...2003 Buell XB9R Appendix D D 3 HOME Figure D 3 Rear Brake Systems Left Side View b1116xcx ...

Page 47: ...D 14 2003 Buell XB9R Appendix D HOME NOTES ...

Page 49: ......

Page 77: ...1 28 2003 Buell XB9R Maintenance HOME NOTES ...

Page 103: ...1 54 2003 Buell XB9R Maintenance HOME NOTES ...

Page 105: ... 2 ...

Page 191: ......

Page 263: ...3 72 2003 Buell XB9R Engine HOME NOTES ...

Page 299: ...4 2 2003 Buell XB9R Fuel System HOME NOTES ...

Page 385: ...4 88 2003 Buell XB9R Fuel System HOME NOTES ...

Page 421: ...4 124 2003 Buell XB9R Fuel System HOME NOTES ...

Page 423: ......

Page 445: ...5 22 2003 Buell XB9R Starter HOME NOTES ...

Page 447: ......

Page 469: ...6 22 2003 Buell XB9R Drive Transmission HOME NOTES ...

Page 497: ...6 50 2003 Buell XB9R Drive Transmission HOME NOTES ...

Page 499: ......