B-12

2003 Buell XB9R: Appendix B

HOME

PUSH-TO-SEAT TERMINALS

The Packard push-to-seat terminal connectors found on Soft-

ail model vehicles are listed below.

●

Ignition Switch [33]

●

Fuse Terminals

●

MAP Sensor [80]

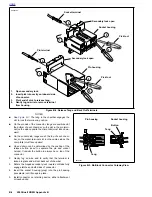

Removing Push-to-Seat Terminals

Like most connectors, Packard push-to-seat terminals are

pulled out the wire end of the connector. To remove a push-

to-seat terminal, proceed as follows:

1.

Remove the connector from the retaining device, if

present.

2.

Bend back the external latch(es) slightly and separate

the pin and socket halves of the connector.

NOTE

Both the Ignition Light/Key Switch and the Main Power con-

nectors are provided with secondary locks. The secondary

lock, which may be molded onto the connector or exist as a

separate piece, aids in terminal retention. Secondary locks

must be opened (or removed) before the terminals can be

extracted from the connector housing.

3.

Open or remove the secondary lock. Bend back the latch

slightly and free one side of the secondary lock, then

repeat the step to release the other side. Rotate the sec-

ondary lock outward on hinge to access the terminals in

the chambers of the connector housing.

4.

Looking in the mating end or terminal side of the connec-

tor (opposite the secondary lock), take note of the larger

cavity next to each terminal.

5.

Insert the pick (Snap-On TT600-3) into the cavity until it

stops. Pivot the end of the pick toward the terminal to

depress the locking tang. Remove the pick and gently

tug on the wire to pull the terminal from the wire end of

the connector. Repeat the step if the terminal is still

locked in place.

NOTE

A series of Packard Electrical Terminal Crimp Tools are avail-

able to install Packard pin and socket terminals on wires. If

new terminals must be installed, see Crimping Instructions.

Installing Push-to-Seat Terminals

NOTE

For wire location purposes, alpha characters are stamped

onto the secondary locks or onto the wire end of the connec-

tor housing.

1.

To install a terminal back into the chamber of the con-

nector housing, use a thin flat blade, like that on an X-

Acto knife, and carefully bend the tang outward away

from the terminal body.

2.

Push the lead into the chamber at the wire end of the

connector. A click is heard when the terminal is properly

seated.

3.

Gently tug on the wire end to verify that the terminal is

locked in place and will not back out of the chamber.

4.

Close or install the secondary lock. Rotate the hinged

secondary lock inward until tabs fully engage latches on

both sides of connector.

5.

Push the pin and socket halves of the connector together

until the latches “click.”

6.

Install connector on retaining device, if present.

Summary of Contents for XB9R 2003

Page 2: ...1 2 Edit Me Printed June 5 2002 12 26 pm ...

Page 35: ...D 2 2003 Buell XB9R Appendix D HOME Figure D 2 Rear Brake Systems Top View b1115xbx ...

Page 36: ...2003 Buell XB9R Appendix D D 3 HOME Figure D 3 Rear Brake Systems Left Side View b1116xcx ...

Page 47: ...D 14 2003 Buell XB9R Appendix D HOME NOTES ...

Page 49: ......

Page 77: ...1 28 2003 Buell XB9R Maintenance HOME NOTES ...

Page 103: ...1 54 2003 Buell XB9R Maintenance HOME NOTES ...

Page 105: ... 2 ...

Page 191: ......

Page 263: ...3 72 2003 Buell XB9R Engine HOME NOTES ...

Page 299: ...4 2 2003 Buell XB9R Fuel System HOME NOTES ...

Page 385: ...4 88 2003 Buell XB9R Fuel System HOME NOTES ...

Page 421: ...4 124 2003 Buell XB9R Fuel System HOME NOTES ...

Page 423: ......

Page 445: ...5 22 2003 Buell XB9R Starter HOME NOTES ...

Page 447: ......

Page 469: ...6 22 2003 Buell XB9R Drive Transmission HOME NOTES ...

Page 497: ...6 50 2003 Buell XB9R Drive Transmission HOME NOTES ...

Page 499: ......