2003 Buell XB9R: Maintenance 1-29

HOME

PRIMARY CHAIN 1.10

INSPECTION

Check primary chain tension:

●

At the 1000 mile (1600 km) service interval.

●

At every 5000 mile (8000 km) service interval

thereafter.

See

Figure 1-28.

Measure primary chain tension through the

inspection cover opening. Adjust primary chains not meeting

vertical free play specifications.

1.

See

Figure 1-28.

Remove two fasteners with captive

washers and primary chain inspection cover with gasket

from primary cover.

2.

See

Figure 1-29.

Check primary chain tension by mea-

suring vertical free play.

a. Measure vertical free play through chain inspection

cover opening.

b.

Rotate engine to move primary chain to a different

position on sprockets.

c. Measure vertical free play several times, each time

with primary chain moved so that the measurement

is taken with sprockets rotated to the tightest chain

position.

3.

The tightest measurement taken in Step 2 must be within

the specifications listed in

Table 1-9.

If necessary, adjust

as described under

1.10 PRIMARY CHAIN

in

ADJUST-

MENT,

NOTE

The initial primary chain vertical free play specification used

at the assembly plant is 1/4-1/2 in. (6.4-12.7 mm) with a cold

engine. The 1/4 in. (6.4 mm) minimum is only allowed at the

absolute tightest point in the drive, as measured with special-

ized factory equipment. If a chain has less than 1/4 in.

(6.4 mm) vertical free play (with a cold engine), adjust free

play to the “field” specification of 3/8-1/2 in. (9.5-12.7 mm).

The looser specification will avoid overtightening, which might

otherwise occur during adjustment using “non-factory” equip-

ment and methods.

4.

See

Figure 1-28.

Install primary chain inspection cover

and gasket to primary cover using two fasteners with

captive washers. Tighten fasteners to 40-60

in-lbs

(5-

7 Nm).

Figure 1-28. Primary Chain Inspection Cover

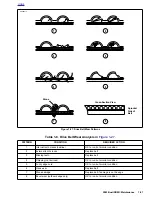

Figure 1-29. Measuring Primary Chain Tension

Table 1-9. Primary Chain Tension

ENGINE

TEMPERATURE

FREE PLAY

Cold

3/8-1/2 in.

9.5-12.7 mm

Hot (normal running

temperature)

1/4-3/8 in.

6.4-9.5 mm

8356

b0085a6x

Summary of Contents for XB9R 2003

Page 2: ...1 2 Edit Me Printed June 5 2002 12 26 pm ...

Page 35: ...D 2 2003 Buell XB9R Appendix D HOME Figure D 2 Rear Brake Systems Top View b1115xbx ...

Page 36: ...2003 Buell XB9R Appendix D D 3 HOME Figure D 3 Rear Brake Systems Left Side View b1116xcx ...

Page 47: ...D 14 2003 Buell XB9R Appendix D HOME NOTES ...

Page 49: ......

Page 77: ...1 28 2003 Buell XB9R Maintenance HOME NOTES ...

Page 103: ...1 54 2003 Buell XB9R Maintenance HOME NOTES ...

Page 105: ... 2 ...

Page 191: ......

Page 263: ...3 72 2003 Buell XB9R Engine HOME NOTES ...

Page 299: ...4 2 2003 Buell XB9R Fuel System HOME NOTES ...

Page 385: ...4 88 2003 Buell XB9R Fuel System HOME NOTES ...

Page 421: ...4 124 2003 Buell XB9R Fuel System HOME NOTES ...

Page 423: ......

Page 445: ...5 22 2003 Buell XB9R Starter HOME NOTES ...

Page 447: ......

Page 469: ...6 22 2003 Buell XB9R Drive Transmission HOME NOTES ...

Page 497: ...6 50 2003 Buell XB9R Drive Transmission HOME NOTES ...

Page 499: ......