CC

DD

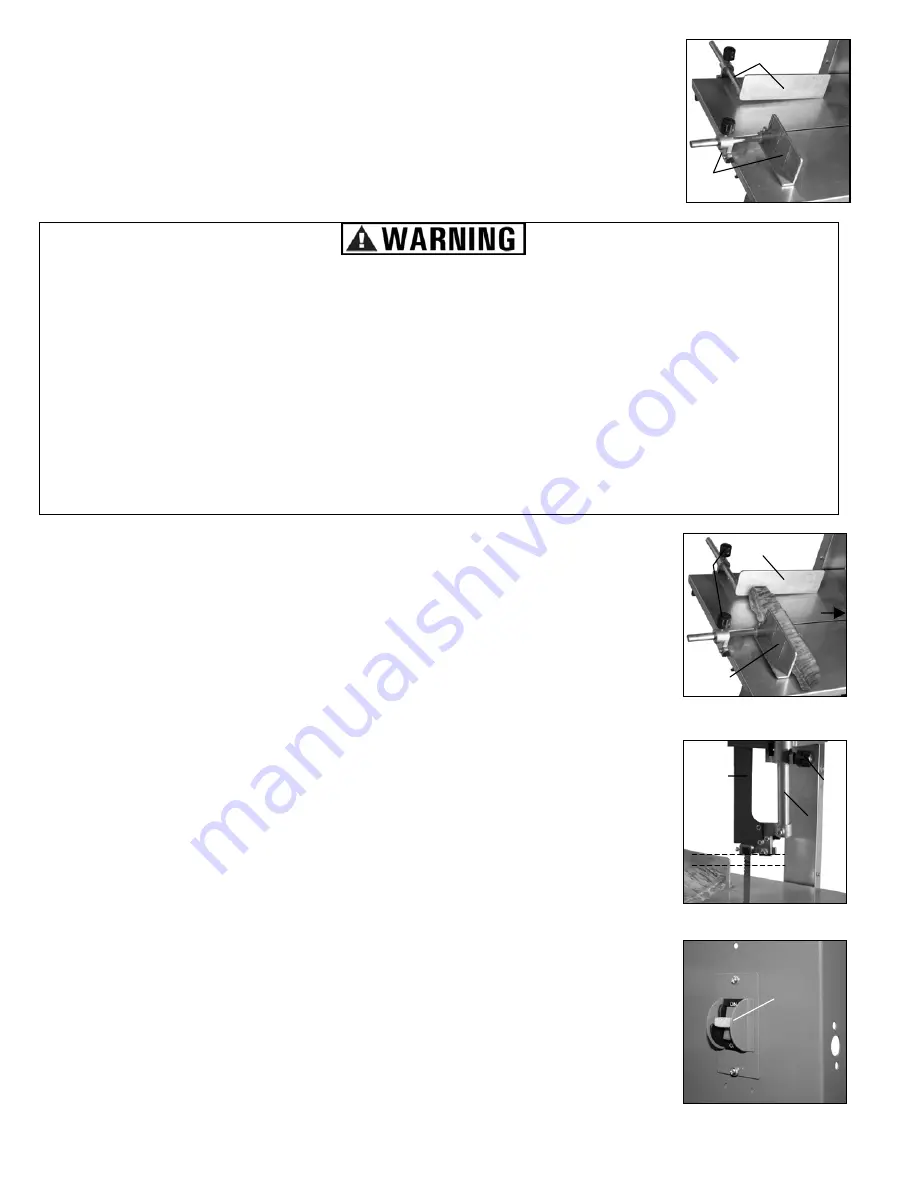

Assembling the Fence and Pusher

The fence (CC) and pusher (DD) have predetermined spaces for attachment to the

table. The fence attaches to the side, the pusher attaches to the end. Using socket

screws, attach the fence and pusher to their respective areas. (Figure 16)

OPERATION

MBSAW Meat Cutting Band Saw w/Meat Grinder Assembly & Operating Instructions

10

NOTE: For best results, chilled or slightly frozen meats make uniform cutting easier.

However, do not cut completely frozen meat as it may damage the blade.

Basic Meat Cutting Procedures

Place the meat on the stainless steel table and position it between the saw blade

in front (EE, out of picture), the pusher (FF), and the fence (GG) on the left. Note:

The fence and the pusher have adjusting knobs (HH) allowing you to adjust the

placement of both, depending on the size of the piece of meat. (Figure 17)

Adjust the vertical placement of the Blade Guard (II) so there is a maximum 1/2"

space between it and the top of the meat to be cut. To adjust the Blade Guard,

loosen the knob (JJ) on the Blade Guard and raise or lower it to expose more or

less of the blade. Once in the desired position, tighten the knob. NOTE: There is

a flat side on the Guide Post (KK) that must face the knob to work properly.

(Figure 18)

Turn the Power On using the ON/OFF switch (LL). Allow the blade to reach full

speed. With one hand on the pusher and the other on the fence, push the table

forward into the rotating blade, careful to keep your hands out of the path of the

blade. (Figure 19)

Cover the machine with a cloth cover when not in use.

Before and after use, wash all parts with warm soapy water.

Wear protective gloves, clothing and eye protection while operating the Band Saw.

Saw blade and grinder knife are sharp!

Use care when using and cleaning the product to prevent injury.

Dull blades require extra effort, which leads to blade breakage, resulting in flying debris and possible injury

to the user or bystanders.

Once the cut is made, turn the machine off and allow the blade to come to a complete stop before

removing the cut meat. Repeat this process until finished with the original piece of meat.

Proper blade tension is important, both for optimum cutting and safety. There should be no

flexibility with the blade.

Figure 16

HH

GG

FF

Figure 17

EE

II

JJ

1/2"

Figure 18

KK

LL

Figure 19

Summary of Contents for IW12BX

Page 13: ...MBSAW Meat Cutting Band Saw w Meat Grinder Assembly Operating Instructions 13 ...

Page 14: ...MBSAW Meat Cutting Band Saw w Meat Grinder Assembly Operating Instructions 14 NOTES ...

Page 15: ...MBSAW Meat Cutting Band Saw w Meat Grinder Assembly Operating Instructions 15 NOTES ...

Page 16: ...NOTES MEGRINDUL Meat Grinder Assembly Operating Instructions 16 ...