7

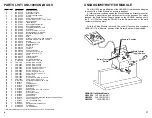

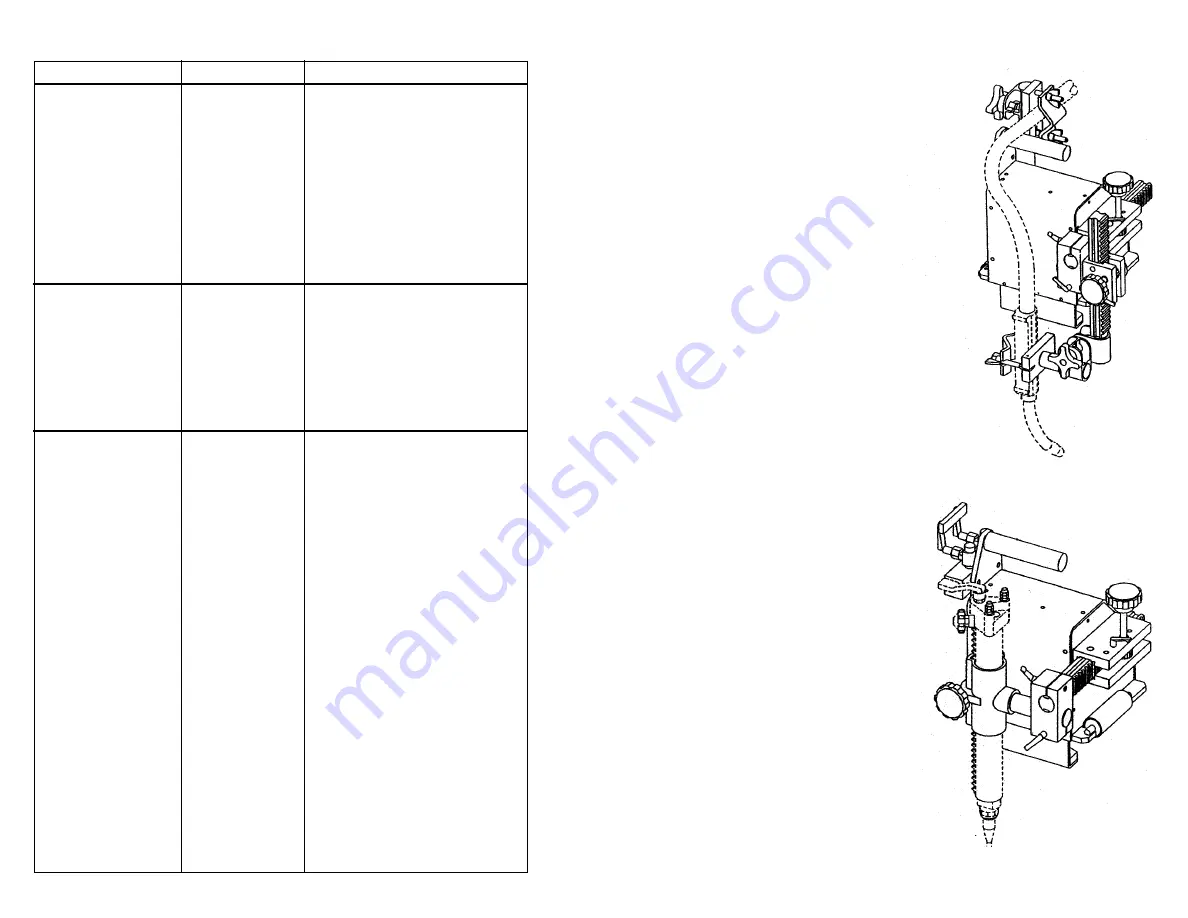

UNI-1100 UNI-BUG II Welding Kit 120 VAC

UNI-1102 UNI-BUG II Welding Kit 240 VAC

UNI-1104 UNI-BUG II Welding Kit 42 VAC

Net Weight:

19 lbs. (8.62 kg)

Shipping

Weight:

21 lbs. (9.53 kg)

Includes:

(1) BUG-1855 UNI-BUG Welding Group

(1) UNI-100_ UNI-BUG II

UNI-1200 UNI-BUG II Cutting Kit 120 VAC

UNI-1202 UNI-BUG II Cutting Kit 240 VAC

UNI-1204 UNI-BUG II Cutting Kit 42 VAC

Net Weight:

20 lbs. (9.07 kg)

Shipping

Weight:

22 lbs. (10.0 kg)

Includes:

(1) BUG-1875 UNI-BUG Cutting Group

(1) UNI-100_ UNI-BUG II

UNI-BUG II KITS

18

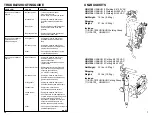

PROBLEM

CAUSE

REMEDY

Does not run. Indicator

No input power.

- Turn on the circuit breaker.

light off.

- Plug in the line cord.

- Insure there is power at the outlet.

Broken Wire.

- Unplug the machine from power.

- Examine internally and rewire at

fault.

Bad circuit.

- Replace if breaker has input power

and no output when in the “ON”

position.

Bad travel switch.

- Replace if switch has input power

and no output when ‘ON”.

Does not run. Indicator

Wiring short.

- Unplug the machine from power.

light off and circuit

Examine internally and rewire at

breaker is tripped.

fault.

Burned out part.

- Unplug the machine from power.

Examine internally and replace any

part that looks burned up.

Other.

- Can only be determined by factory

or qualified repair person.

Does not run. Indicator

Bad connection.

- Unplug the machine from power.

light on.

Examine internally and fix any

broken connections.

- Tighten terminal screws on speed

control board.

Open transformer. - Replace the transformer if there is

input power on the primary and no

output on the secondary.

(12 VAC/CT is expected)

Burned out part.

- Unplug the machine from power.

Examine internally and replace any

part that looks burned up.

Wiring short.

- Unplug the machine from power.

Examine internally and rewire fault.

Failed motor.

- Replace the motor if it has

input voltage and does not turn.

Failed control

- Unplug the machine from power.

card.

Check the card for damaged traces

or parts. Repair or replace if required.

- Verify the card has 12 VAC/CT

input power. Replace the card if the

output to the motor leads is OV

with the speed knob at maximum.

Other.

- Can only be determined by factory or a

qualified repair person.

TROUBLESHOOTING GUIDE

MORE