CPsingle, CPdouble

7.2 Replacing the hose

– Turn off gas supply.

– Switch the device off and disconnect power supply.

– Remove the supplying and draining hoses from the pump (

Take care of the safety instructions!

).

– Loosen the centre knurled screw but do not remove it. Push the screw aside.

– Pull off the cover.

– Pull the connections sidewards and remove the hose.

– Replace the hose (Bühler spare part) and remount the pump in reverse order.

– Reconnect power supply.

7.3 Spare parts and accessories

Please also specify the model and serial number when ordering parts.

Upgrade and expansion parts can be found in our catalog.

Available spare parts:

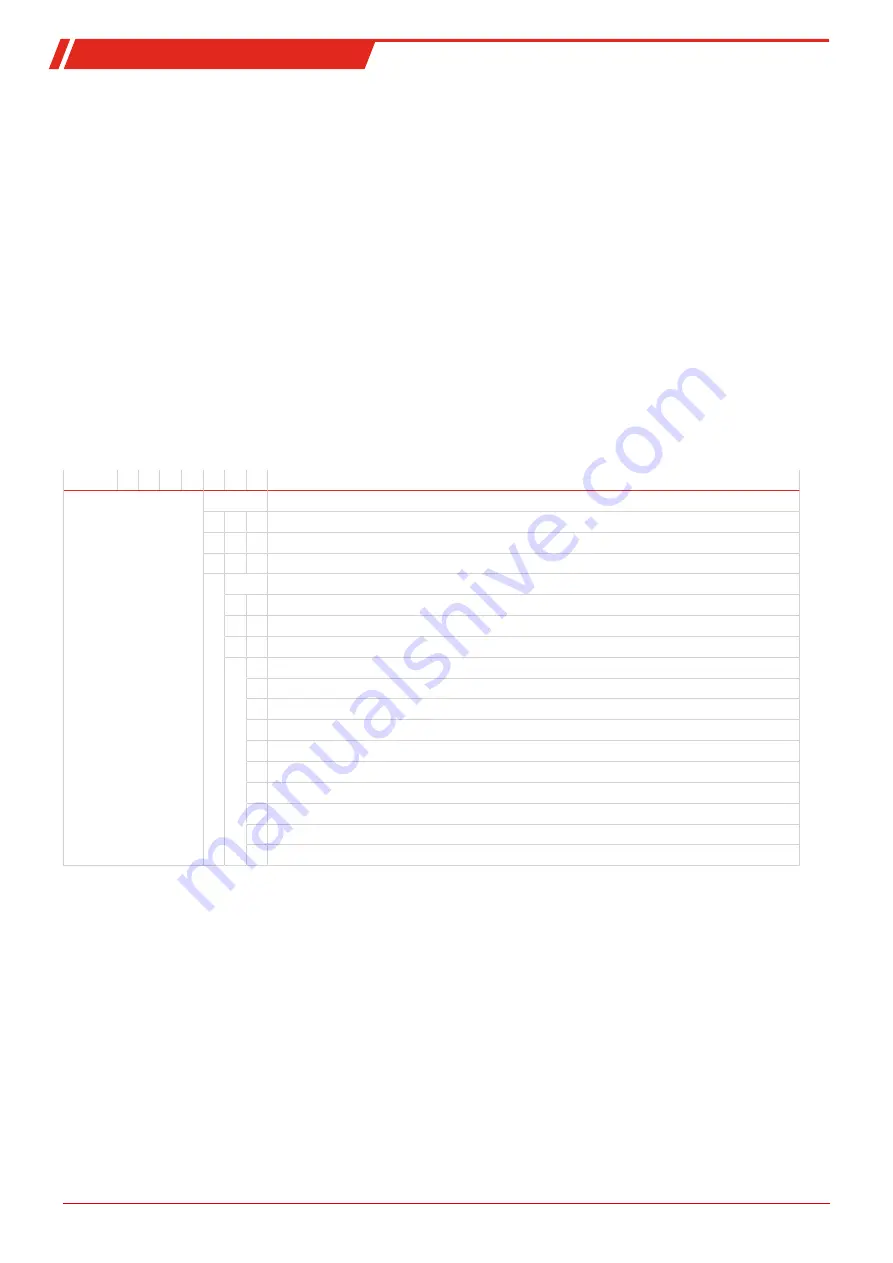

7.3.1 Ordering information replacement hoses for 0.3 l/h pumps

4492

0 0

3

5

X X X Product characteristics

Output per liter

*

0

0.3 L/h

1

1 L/h or 1.5 L/h

2

0.01 L/h or 0.06 L/h

Hose material

1

Norprene

2

Fluran

3

Marprene

Hose connection

1 straight hose nipple

2 angled hose nipple

3 straight and angled hose nipple

4 Screw connection (metric)

5 Screw-in connection (US)

6 angled hose nipple and screw connection (metric)

7 angled hose nipple and screw connection (US)

8 straight hose nipple and screw connection (metric)

9 straight hose nipple and screw connection (US)

* for required flow capacity, see technical data.

Information about hose materials

The standard hose in Norprene has excellent mechanical properties with high chemical resistance to many substances.

Marprene offers a long life for many applications with high chemical resistance, particularly when oxidation agents are present.

This is therefore the first alternative to the standard Norprene hose.

Fluran is particularly beneficial if the condensate contains oils, petrols and other solvents. The mechanical properties should

rather be assessed weaker, so we only recommend this hose material for the specified chemicals.

The flow capacity of Fluran and Marprene hoses is slightly lower.

Other materials are available on request.

13

Bühler Technologies GmbH

BE450021 ◦ 01/2017