General

17

1

General

Please read this Operating Manual through carefully and completely before first using the

Applicator. Pay particular attention to the safety instructions in Section 2.

This Operating Manual must always be within easy reach for any user.

1.1

Scope of use

The HB 700 KD Applicator is for the melting and metered discharge of highly viscous

melts (thermoplastic substances such as hot-melt adhesives, waxes, etc.) as a bead using

interchangeable application tools (use as intended).

1.2

Technical data

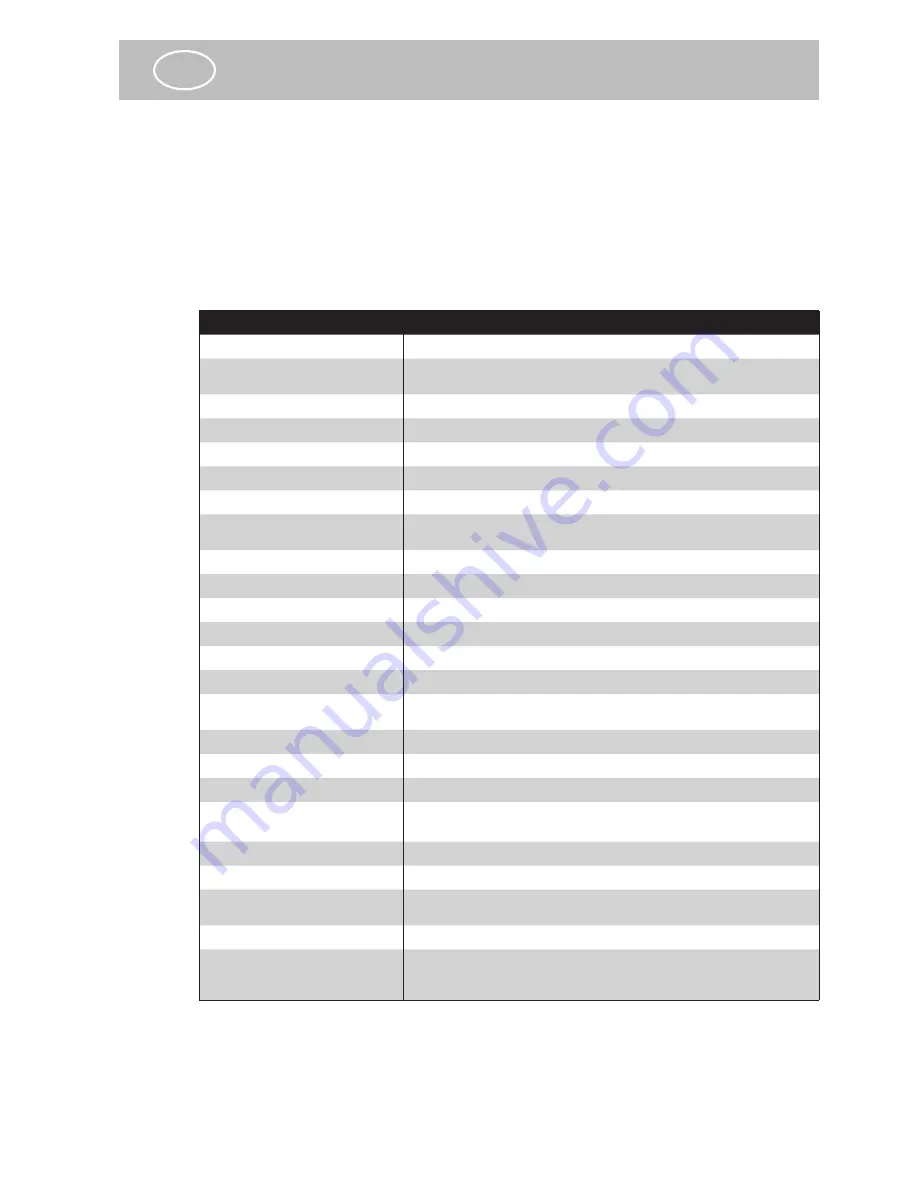

Model

HB 700 KD

Part No.

H211700

Kit includes

Applicator, stainless steel pot, removing tongs for cartridges,

working bracket / workstation (optional)

Weight [kg]

~1.5

Power connection

230V AC / 50 Hz / earthing-pin plug

Power requirement [W]

600

Power consumption [A]

2.6

Protection (as per DIN IEC 34 T5)

IP30

Safety class

(as per DIN VDE 0720)

I (safety earth terminal)

Temperature control

electronic

Temperature limitation [°C]

thermal cut-out (260 ±11)

Operating temperature [°C]

40…210

Temperature constancy [°C]

±2

Factory presetting [°C]

120

Temperature indication

digital via LED display

Automatic temperature reduction

(ACE)

Switched off by factory

Warm-up time [min]

~10

Hot-melting capacity

1 hot melt material cartridge 310 ml

Conveyor system

compressed air

Compressed-air connection [bar]

max. 10 (service unit with quick-action coupling)

The compressed air must be condensate- and acid-free

Operating pressure [bar]

1.5…6.0

Protection against overpressure

limited by reducing valve to 6 bar

Air consumption

(at 5 bar operating pressure)

max. 2 l per trigger actuation

Nozzles (standard)

cone nozzle Ø 3 mm

Length of supply line with

electrical and pneumatic connec-

tions [m]

3.0

GB