MAINTENANCE

Make sure that the plug is removed from the mains when carrying out maintenance work on

the motor.

The machine has been designed to operate over a long period of time with a minimum of

maintenance. Continuous satisfactory operation depends upon proper machine care and

regular cleaning. Before interfering in any way whatsoever with the compressor, please make

sure that the switch button is in the “0”position and the power plug is removed from the

power socket.

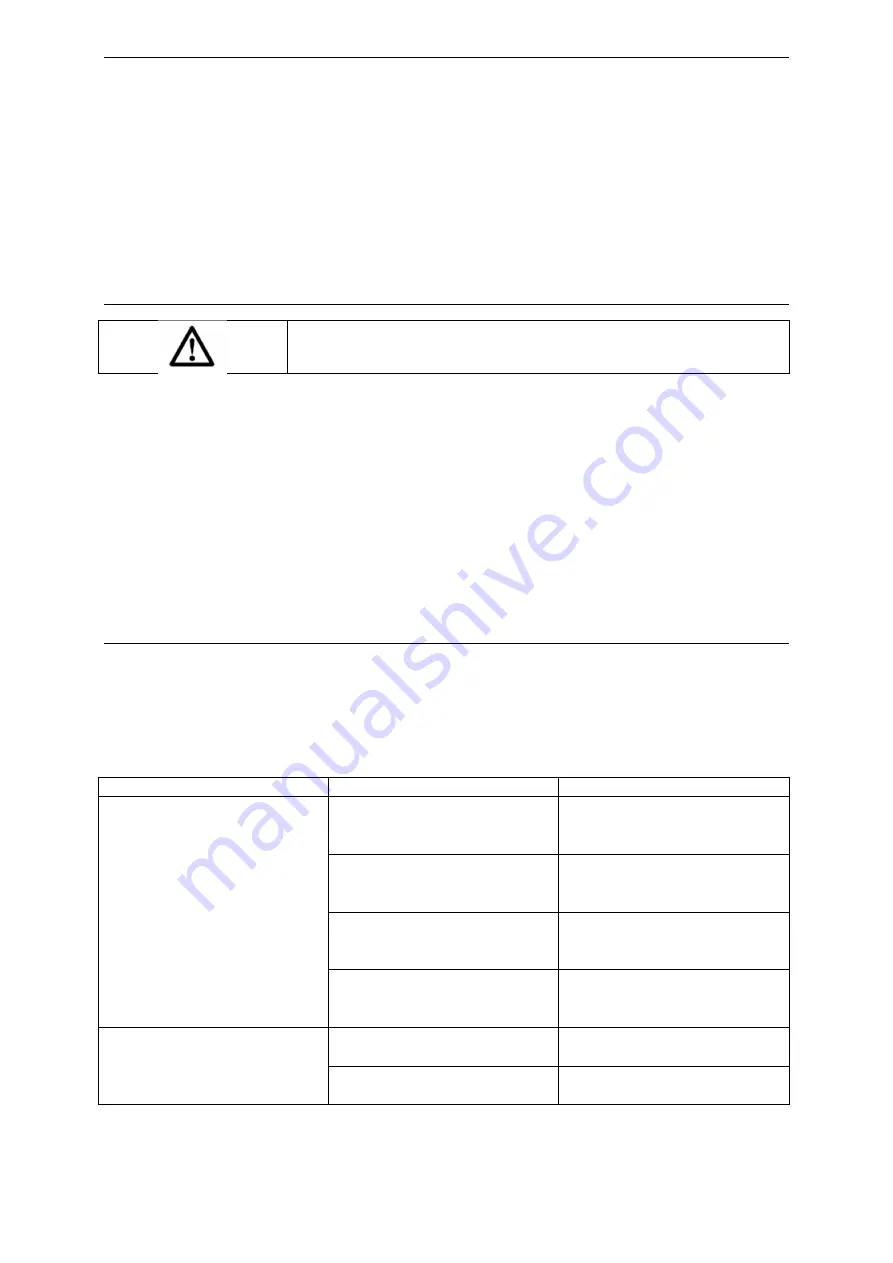

CLEANING

WARNING! For cleaning, do not use any abrasive products (petrol,

alcohol, scraper brush, etc.)! These products can damage the tool

and create accidents and injuries!

The tool shall be switch off and unplug before cleaning.

After each use, clean the housing with a soft and dry cloth. The ventilation slots must always

free from and dust.

If the tool and the ventilation slots are very dirty, you may use a cloth with a soft detergent

and warm water.

You can clean also the cable and accessories if necessary with a dry cloth. Never use water

and detergent for clean them.

TROUBLESHOOTING

When you meet a malfunction with this tool when using it, you can follow this below table to

solve it.

If this table does not solve your problem, please contact our service agent for inspection

Problem

Possible Cause

Solution

The compressor do

not start

The supply alimentation

doesn’t match with the

specification of the product

Contact a professional

electrician to change your

electrical installation

Extension cable are used

or misused

Replace the extension cable

and use them by respecting

the instructions

Operating environment is

too cold (below 0°C)

Do not use this tool in this

kind of environment. You

must change of area

The plug is not well

connected to the supply

connection

Plug again the tool in the

correct way

The compressor cannot

inflate the product

Use of the wrong

accessory

Use the correct accessory

by following the instructions

The product to be inflated

has some defaults

Do not work on a damaged

or not correct product