CARE OF YOUR OPENER

LIMIT AND FORCE ADJUSTMENTS:

Weather conditions may

cause some minor changes

in door operation requiring

some re-adjustments,

particularly during the first

year of operation.

Pages 23 and 24 refer to the

limit and force adjustments.

Only a screwdriver is

required. Follow the

instructions carefully.

Repeat the safety reverse test (Adjustment

Step 3, page 25) after any adjustment of limits or

force.

28

NOTICE: To comply with FCC and or Industry Canada (IC) rules, adjustment or

modifications of this receiver and/or transmitter are prohibited, except for changing the

code setting or replacing the battery. THERE ARE NO OTHER USER SERVICEABLE PARTS.

Tested to Comply with FCC Standards FOR HOME OR OFFICE USE. Operation is subject to

the following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

MAINTENANCE SCHEDULE

Once a Month

• Manually operate door. If it is unbalanced or

binding, call a trained door systems technician.

• Check to be sure door opens and closes fully.

Adjust limits and/or force if necessary. (See pages

23 and 24.)

• Repeat the safety reverse test. Make any

necessary adjustments. (See Adjustment Step 3.)

Twice a Year

• Check chain tension. Disconnect trolley first. Adjust

if necessary (See page 7).

Once a Year

• Oil door rollers, bearings and hinges. The opener

does not require additional lubrication. Do not

grease the door tracks.

FORCE CONTROLS

1

3

9

7

5

1

3

9

7

5

LIMIT CONTROLS

KG

KG

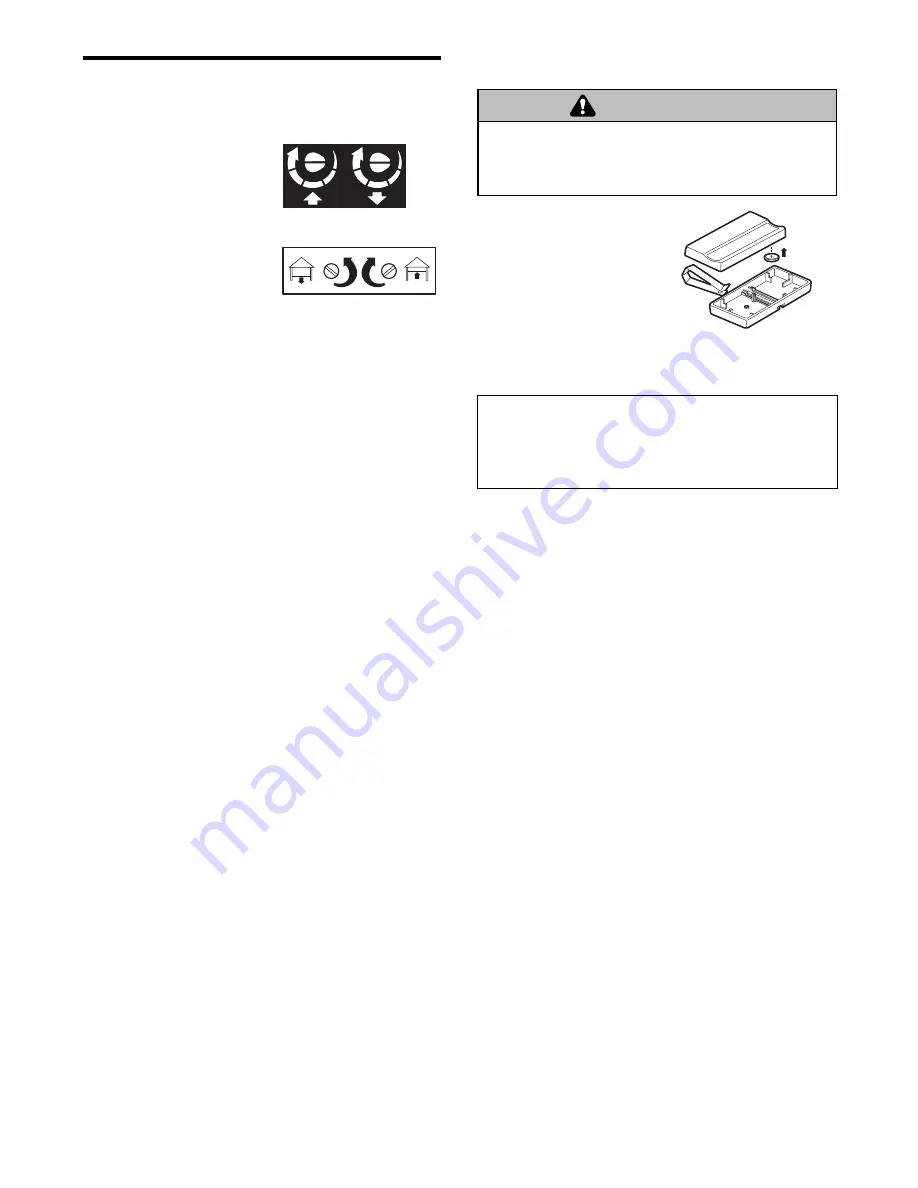

THE REMOTE CONTROL BATTERY

The lithium battery should

produce power for up to

5 years. To replace battery,

use the visor clip or

screwdriver blade to pry

open the case as shown.

Insert battery positive side

up (+).

Dispose of old battery properly.

To prevent possible SERIOUS INJURY or DEATH:

• NEVER allow small children near batteries.

• If battery is swallowed, immediately notify doctor.

WARNING

CAUTION

WARNING

WARNING

Battery

positive

side up (+)