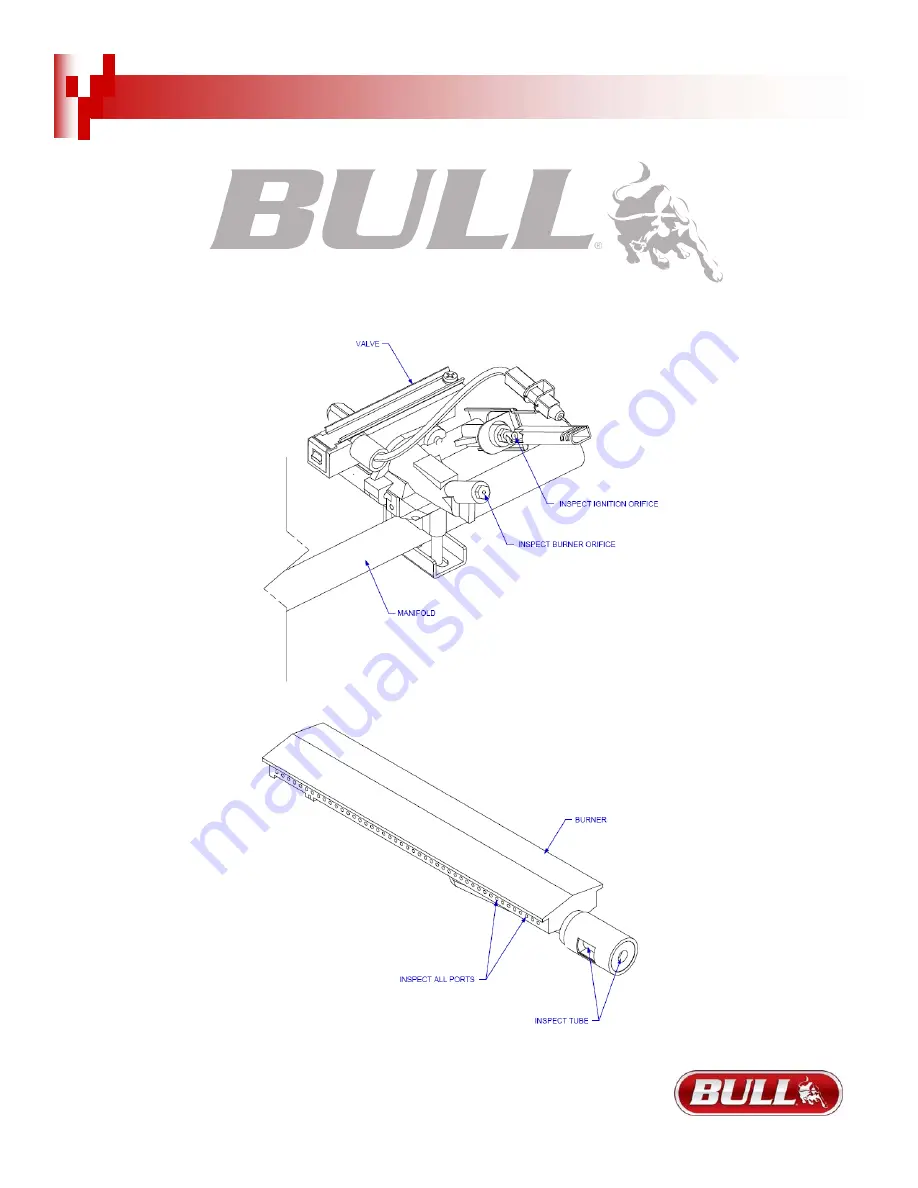

INSPECTING / CLEANING BURNERS AND GAS

VALVE ORIFICES

(CONT.)

2. Light any burner by pushing its control knob in fully and slowly (3 to 4 seconds) turning it about 1/4 turn to the left (counter-clockwise) until a

click is heard. The 3 to 4 second duration should provide enough gas to light the burner. If the burner does not light, immediately return the

control knob to “OFF”, wait several minutes for the gas to disperse, and repeat the process. After burner lights successfully, turn control knob to

“OFF”.

3. Repeat process for each control knob/igniter, in turn, ensuring that other knobs are in “OFF” position as you perform each check.

4. If any burners fail to light after several attempts, discontinue gas supply at source and re-inspect for obstructions to gas flow and orifices.

11

Summary of Contents for 47628

Page 24: ...EXPLODED ILLUSTRATION 23 ...