www.bullard.com

2

Principle o

f Oper

ation / Battery P

ack

EVAHL Series - Principle of Operation

The EVAHL Series Powered Air-Purifying Respirator (PAPR) System is configured in

six parts:

1. The blower and belt assembly:

EVAHL1 Blower Unit

EVABELT1 or EVABELT2 Comfort Belt, Decon Belt

PA1AFI Air Flow Indicator

2. The battery pack (Part No. EVAHLBAT1). One fully charged pack will power the blower

for approximately 4 to 10 hours depending upon factors such as speed, cartridge

selected and cartridge loading.

3. The breathing tube, which is available in three different types and three lengths:

PAHBT Powered Air Hood Breathing Tube Assembly (standard length - 26")

PAHBTXS Powered Air Hood Breathing Tube Assembly (short length - 22")

PAHBTXL Powered Air Hood Breathing Tube Assembly (long length - 32")

PA1BT Hood breathing tube assembly with clamp (standard length - 26")

PA1BTXS Hood breathing tube assembly with clamp (short length - 22")

PA1BTXL Hood breathing tube assembly with clamp (long length - 32")

PA20LFBT Loose fitting facepiece breathing tube assembly (standard length - 32")

PA20LFBTXS Loose fitting facepiece breathing tube assembly (short length - 26")

PA20LFBTXL Loose fitting facepiece breathing tube assembly (long length - 38")

4. The High Efficiency Particulate Arrestance (HEPA) filter or chemical filter cartridge.

5. The hood with headband suspension (except for the RT Series) and/or hard hat, or

loose fitting facepiece. The following hood models may be used with the EVAHL Series

blower unit:

RT1, RT1T Hood with long inner and outer bib (NIOSH approved for use without a

headband suspension)

RT2, RT2T Hood with long inner and outer bib (NIOSH approved for use without a

headband suspension)

RT3, RT3T Hood with long inner and outer bib (NIOSH approved for use without a

headband suspension)

RT4, RT4T Hood with long inner and outer bib (NIOSH approved for use without a

headband suspension)

20TJN, 20TJNT Hood

20TICN, 20TICNT Hood with inner bib

20TICH, 20TICHT Hood for use with Bullard hard hat

20TICSN, 20TICSNT Hood with taped and sealed seams

20SICN, 20SICNT Hood with taped and sealed seams

20SICVN, 20SICVNT Hood with taped and sealed seams and PVC lens

20SICH, 20SICHT Hood with taped and sealed seams for use with Bullard hard hat

20SICVH, 20SICVHT Hood with taped and sealed seams and PVC lens for use with

Bullard hard hat

20LFM Loose fitting facepiece, medium size

20LFL Loose fitting facepiece, large size

20LFXL Loose fitting facepiece, extra large size

20LF2S Loose fitting facepiece (narrow profile), small size

20LF2M Loose fitting facepiece (narrow profile), medium size

20LF2L Loose fitting facepiece (narrow profile), large size

6. The Battery Charger:

EVAHLSMC Quick charger, single port

EVAHLGC Gang charger, six port

The blower unit draws in ambient air through the cartridges. The purified air is blown

into the wearer’s hood through the breathing tube. A flow indicator is provided to check

that there is an adequate volume of air available to the wearer prior to use. The system is

designed to operate at a minimum air flow of approximately 7 cubic feet of air per minute

(198 liters per minute) in the hood under normal use on the standard speed setting, and

8.5 cubic feet of air per minute (240 liters per minute) in the hood under normal use

on the high speed setting. A feedback loop from the Mass Flow Sensor to the impellor

continually monitors and adjusts the air flow to keep it constant at the design set point.

The units are designed for use at temperatures from 23ºF to 129ºF (-5ºC to 55ºC).

A high temperature alarm will sound at 122ºF (50ºC).

The battery pack mounts in a compartment on the back of the blower. A fully charged

battery pack will power the blower for approximately 4 to 10 hours depending upon

factors such as speed selected, cartridge selected, and filter/cartridge loading.

The EVAHL Series Blower is equipped with two alarms: A 77 db continuous alarm will sound

when the air flow falls below approximately 185 lpm and a 77db intermittent chirp alarm will

activate to indicate that the battery has approximately 15 minutes of remaining capacity.

Type C Airline Respirators -

CC20 Series (TC-19C-154), RT Series (TC-19C-412)

Most of the same headpieces approved for use with the CC20 and RT Series of supplied

air respirators (SAR) are also approved for use with the EVAHL Series of powered air-

purifying respirators. CC20 and RT Series respirators provide a high level of respiratory

protection and user comfort over long work periods, in a wide variety of hazardous

environments.

The CC2 and RT SAR air flow control devices and other components are described in the

CC20 and RT Series User Instructions.

Battery Pack

One fully charged battery pack will power the blower for approximately 4 to 10 hours

depending upon factors such as speed selected, cartridge selected and filer/cartridge

loading.

WARNING:

EXPLOSION HAZARD

• Only use Bullard battery part number: EVAHLBAT1. Substitution of any other

battery pack may impair suitability for Division 2.

• Do no charge battery packs in hazardous locations.

• Only charge using Bullard Desktop battery pack chargers.

• Do not insert or remove the battery pack unless the area is known to be free

of ignitable concentrations.

NOTE

The battery has built-in short circuit protection. In the event of a short circuit, an

internal polyfuse will trip. The fuse will reset itself within 5-10 seconds allowing the

battery to resume normal operation.

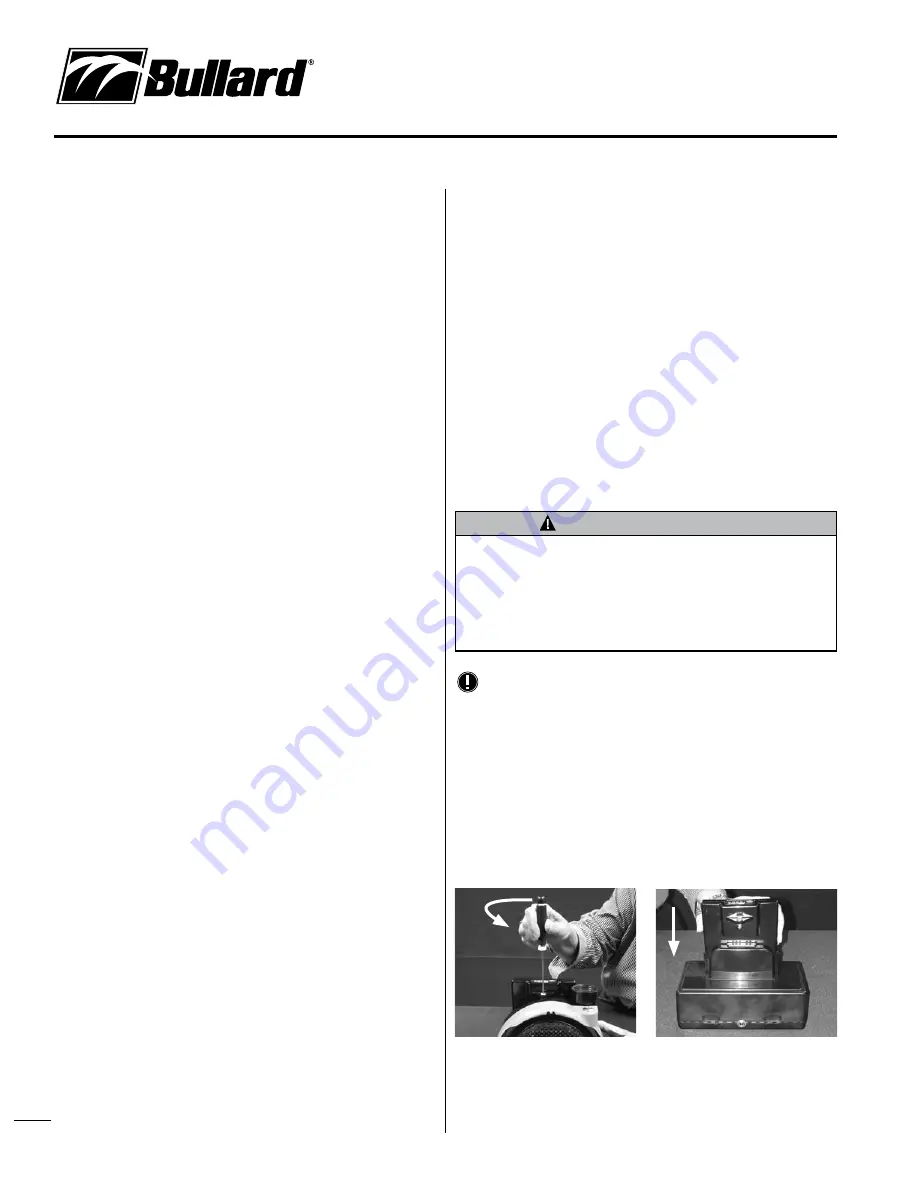

To charge the battery pack, do the following:

• Use a flat head tool to release the battery from the blower. (See Figure 1.)

• Place battery into the charging port of the battery charger. (See Figure 2.)

• Connect the battery charger to a 110-volt AC electrical outlet.

• Charge the battery pack for approximately 4 hours. While the battery is charging, the

light on the charger will remain red. The charger light will illuminate green when charging

is complete.

Table-top gang chargers with 6 ports are also available.

Figure 1

Figure 2