Air-Purifying Elements

6

HE particulate filters are 99.97% effective against all particulate

aerosols.

Filters and cartridges are supplied in quantities of six per box.

The following abbreviations are approved by NIOSH to indicate

the particulates, gases or vapors which are removed by the

gas/vapor cartridges:

CL

Chlorine

CD

Chlorine Dioxide

HC

Hydrogen Chloride

SD

Sulfur Dioxide

FM

Formaldehyde

AM

Ammonia

MA

Methylamine

OV

Organic Vapors

HF

Hydrogen Fluoride

HE

High Efficiency Particulate Air Filter for Powered

Air-Purifying Respirators

Protection

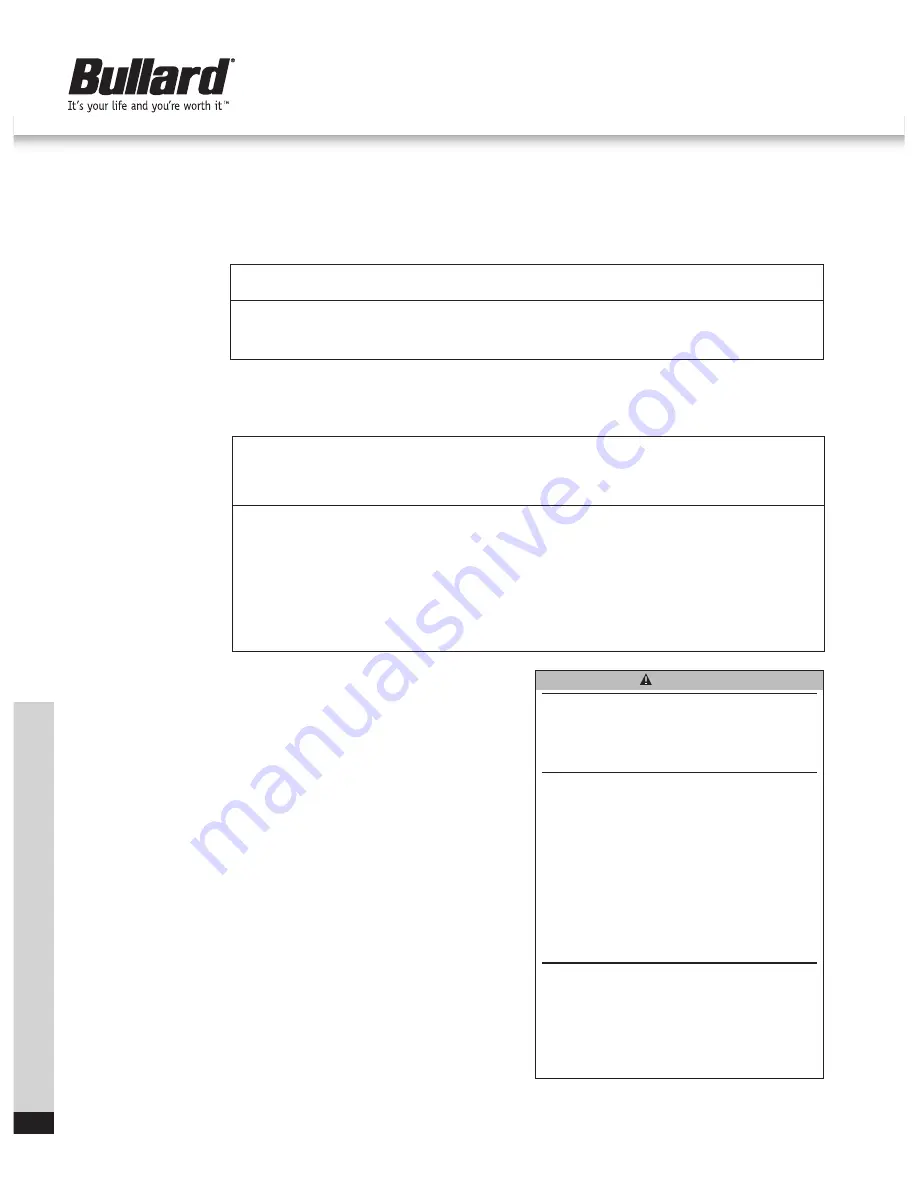

Filter/Cartridge Type

Quantity

NIOSH / ANSI Color Code

for Cartridge Label

HE

PA3HE

2

Purple

OV/CL/HC/SD/CD/HF/HE

PA3OVAGHE

3

Yellow and Purple

CL/HC/SD/CD/HF/FM/AM/MA/HE

PA3NBC*

3

Olive Green and Purple

www.bullard.com

PA3NBC CARTRIDGE

CHEMICAL WARFARE GAS PERFORMANCE TESTING

Gas Challenge

Test

Flow

Breakthrough

Time to

Concentration

Rate

Concentration

Breakthrough

DMMP

3000 mg/m3

50 lpm

.04 mg/m3

>120 minutes*

Sarin (GB)

4000 mg/m3

32 lpm

.04 mg/m3

>120 minutes*

Cyanogen Chloride (CK)

4000 mg/m3

32 lpm

8.0 mg/m3

30 minutes*

Chloropicrin (PS)

15000 mg/m3

30 lpm

0.7 mg/m3

60 minutes

Hydrogen Cyanide (AC)

5500 mg/m3

30 lpm

5.0 mg/m3

>30 minutes

Tear Gas (CS)

23 mg/m3

64 lpm

0.4 mg/m3

>480 minutes

Tear Gas (CN)

101 mg/m3

64 lpm

0.3 mg/m3

>480 minutes

*These tests are part of the performance specifications for the C2A1 military canister. The PA3NBC Cartridge meets or exceeds the

performance requirements of the C2A1 canister for these gases.

*The PA3NBC cartridge provides protection for acid gases, formaldehyde, and ammonia and therefore is effective against a wide range of Toxic Industrial

Chemicals. The High Efficiency (HE) Particulate Filter provides protection against airborne bacteria, viruses, and other particulates. Although not NIOSH-

approved for use against the following contaminants, independent laboratories have tested and verified that the PA3NBC cartridge is effective against

many chemical warfare agents and/or their recognized surrogates. These agents/surrogates are listed below.

WARNING

Use only the cartridge described in the above table. Used/particulate-

laden cartridges must be changed as a set and not individually. All

cartridges must be of the same type. Do not change cartridges while in

a hazardous atmosphere. Incorrect cartridge selection will invalidate all

performance statements and approvals for this equipment.

Three (3) of the same type of cartridge must be used on the

PA3BU/PA3ISBU blower unit, with the exception of the PA3HE filters

which are used two (2) at a time, in conjunction with the PA3PG plug.

DO NOT use the PA3PG plug to close off a port with any other cartridge

type.

The PA3NBC cartridges and PA3BU blower should only be used with the

20SICVH and 20SICV hoods. These hoods are made of Tychem SL, which

has been tested by DuPont and shown to be effective against chemical

warfare agents. These hoods also feature a press polished vinyl lens

adequate for hospital preparedness applications.

These respirators are not NIOSH-approved for use against chemical

warfare agents.

The respirator and cartridges should not be used beyond eight (8) hours

after initial exposure to chemical warfare agents to avoid possibility of

agent permeation. If liquid exposure is encountered, the respirator

should not be used for more than two (2) hours.

Follow established cartridge change schedules to ensure that cartridges

are replaced before breakthrough occurs. Failure to follow these

warnings could result in death or serious injury.

PA3BU/PA3ISBU Air-Purifying Elements

Principle of Operation

The following filter/cartridge protection classification applies when used with any of the hoods or loose fitting facepieces. In the following

table “Quantity” refers to the number of filters/cartridges which must be attached to the blower unit to provide the required protection.