www.bullard.com

PA30IS Series Powered Air-Purifying Respirator

PA3IS Blower Assembly User Manual

7

RT Hood U

se/Loose-Fitting F

acepiece U

se

RT Series Hood Use

Installing Breathing Tube Assembly in RT Series

Respirator Hoods

For hoods without a threaded port at the

rear, Breathing Tubes PA1BT, PA1BTXS

and PA1BTXL will attach to the hood with a

clamp as follows:

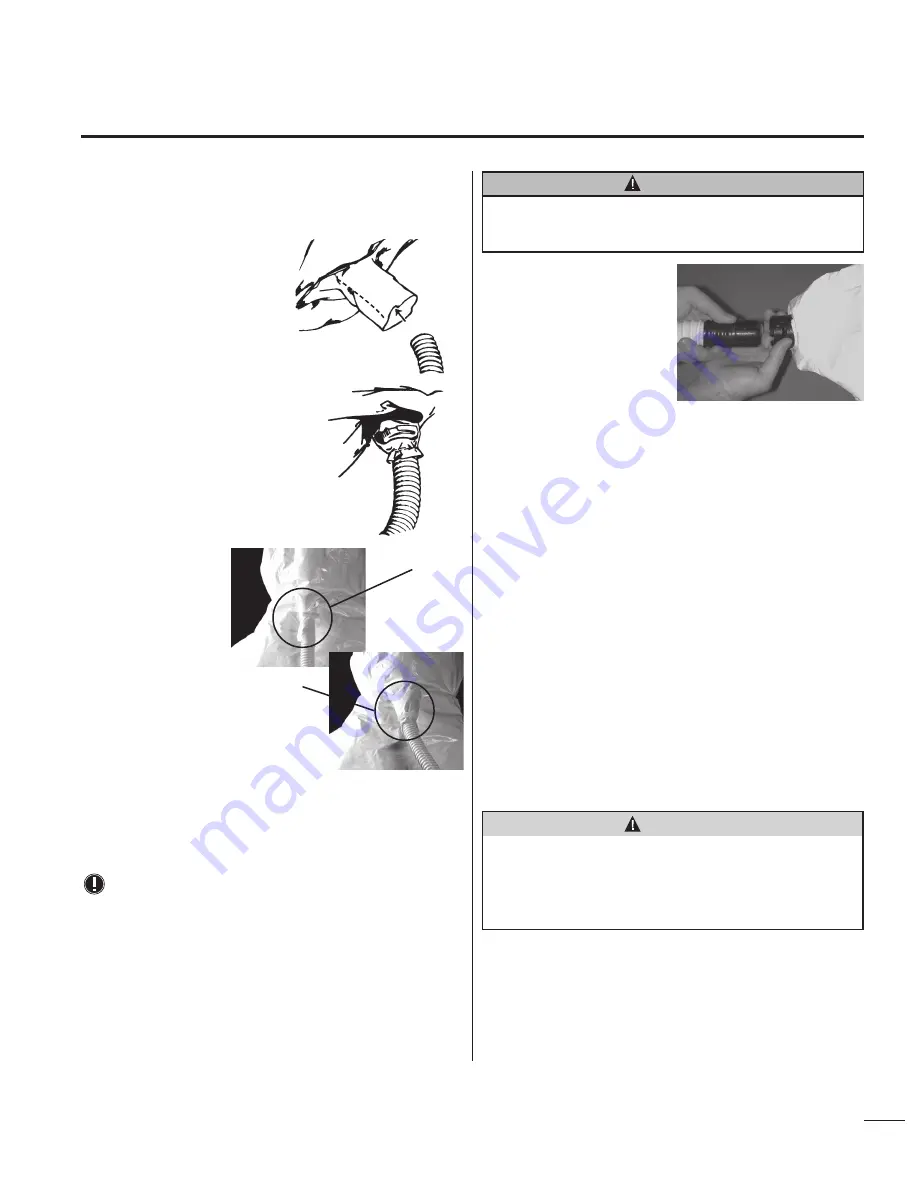

1. Remove nylon clamp from the breathing

tube (see Figure 12).

2. Insert the open end of the breathing

tube approximately five inches into

hood’s air entry sleeve (see Figure 19).

Do not insert breathing tube into hood air

entry sleeve more than 6 inches as it may

cause a flow restriction.

3. Install nylon clamp over air entry sleeve and

breathing tube. If desired, 2 or more clamps

may be used(see Figure 20). The air entry

sleeve seams should be on the sides of the

breathing tube when properly installed and

worn.

4. Engage clamp locks and

squeeze together until tight.

Air entry sleeve should not

be twisted or restricted

(see Figure 21). If so, then

remove the clamp and

repeat steps 2-4.

5. With PAPR blower unit

running, put on RT Series

respirator hood. Pull the

hood over your head until

the neck cuff is securely

around your neck.

6. Ensure that the neck cuff

is down below the chin and

that the air outlets of the cuff are not restricted. If the neck cuff (see Figure

17) is not below the chin, then pull down before continuing (See Figure 18).

For hoods with a threaded port at the rear (designated with a “T” suffix),

Breathing Tubes PAHBT, PAHBTXS, PAHBTXL will attach to the hood by the

threading into the port at the rear (See Figure 13A).

NOTE

The RT3 and RT4 hoods have an adjustable velcro strap near the top of

the lens that allows the user to customize the curvature of the lens to

his/her personal preference. This strap may be removed if desired.

7. Make sure that the breathing tube is not twisted after donning.

8. T uck inner bib of hood into shirt or protective clothing (see Figure 16).

9. Pull respirator outer bib over collar of shirt or protective clothing. Pull the long

outer bib down on the outside of clothing and secure with tie down straps or

tape (if employer operating procedures will allow.)

WARNING

The user should ensure that the neck cuff is unrestricted all around the neck

to allow proper inflation and reduce restrictions.

Battery run time will be reduced by a restricted or improperly donned hood.

Loose-Fitting

Facepiece Use

Installing Breathing

Tube Assembly

in Loose-Fitting

Facepieces

1. The 20LFM, 20LFL, 20LFXL, 20LF2S,

20LF2M and 20LF2L loose-fitting

facepieces have a sewn-in breathing tube connector on the back. The

PA20LFBT breathing tube has a special connector on the hood end with

bayonet type pins.

2. Insert the bayonet connector of the PA20LFBT breathing tube in the hood

connector and turn clockwise until it locks in place (see Figure 22).

Available in extra large 20LFXL, large 20LF2L or 20LFL, medium 20LF2M or

20LFM, and small 20LF2S. Select the size that fits most comfortably and matches

your head size. Remove the protective cover from the visor. Pull the hood over

your head and adjust the headband around your head and the elasticized edge

of the faceseal under your chin. Make sure that the breathing tube is not twisted

after donning.

Final Donning:

• Attach the other end of breathing tube to blower unit (if not already

attached) by screwing adapters together.

• Remove any protective film covering the lens of the headpiece.

• Put on the belt and blower assembly and make any final adjustments to the

belt as necessary, keeping the breathing tube and hood behind the head.

• Turn the blower on by depressing and holding the on/off switch for

approximately 1 second.

• Buckle the belt onto the waist (blower unit should be in the lower back of the

wearer).

• Don the headpiece.

• Place the hood on the head making any final adjustments to the fit as

required at this time to ensure a comfortable and stable fit.

• Tuck inner bib into coveralls or shirt if using a hood with inner bib.

Figure 19

Figure 20

Twisted – incorrect

Correct

Figure 21

Figure 22

Do not enter a hazardous area until you are sure that the blower and hood are

fully operational and the blower is running. The user should periodically leave the

hazardous area to check the airflow through the system. If the low battery or low flow

alarm should sound, or if the user experiences any difficulty in breathing, or senses

any taste or any odors from the hazard, the user should leave the hazardous area

immediately. Failure to observe these warnings could result in death or serious injury.

WARNING