6

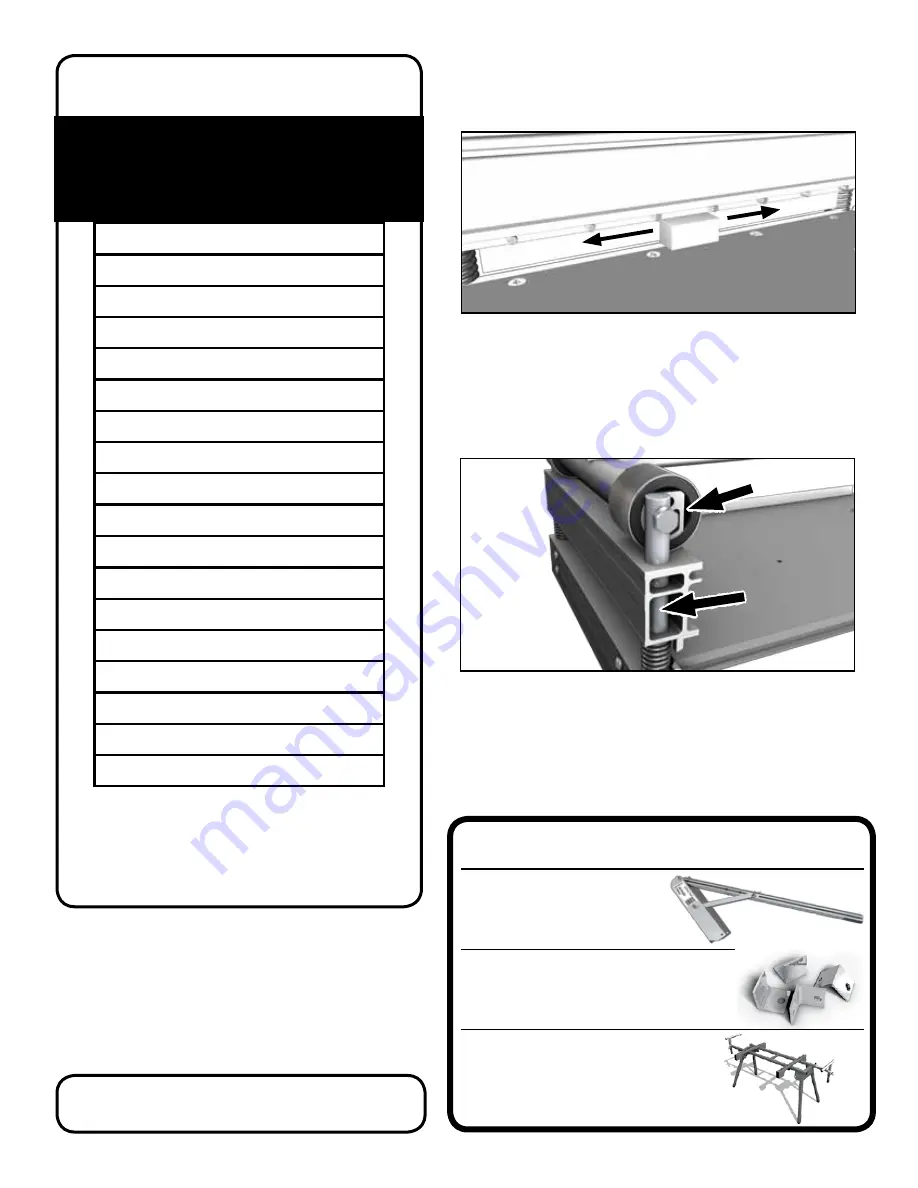

AccESSORIES

All Angle Fence

Item #701AF

Set any angle from 0

º

to 90

º

Mounting Bracket

Item #200MB

Brackets for mounting your shear to a stand

Shear Stand

Item #709

Allows you to cut with the shear

off the ground�

Honing the blade

mAInTEnAncE

Push the handle down until blade is 1/4” (6mm) open.

Lay the hone stone against the flat face of the blade

(side toward the table). Slide from end to end 2 or 3 times.

This removes the small burr formed when cutting hard

products.

Hone every 100 cuts

Greasing / Lubricating

After every 100 cuts, it is recommended that you lubricate

the wear points of the pins and the bearings as shown.

Use a light oil (i.e. 10W motor oil). This will prevent the

machine from wearing out prematurely. Apply grease

(wheel bearing grease) frequently to the bearings where

indicated�

Oil

Grease

Your EZ Shear cuts a wide variety of products.

Please refer to this cut guide for

recommended products and thicknesses.

Please note

: Approved materials may vary in density

and hardness. If extreme pressure is required to cut

a product, it may result in damage to your machine.

Please contact Bullet Tools before proceeding. Warranty

is void if an unapproved product damages the machine.

FLR CUT GUIDE

Maximum Thickness = 15mm or 5/8”

Material

Laminate Flooring

Engineered Wood

Commercial Vinyl

Luxury Vinyl Tile

Parquet

Permastone

™

PVC Tile

Rubber Cove Base

Rubber Tile

Soft Plastic

Siding, Fiber Cement Board

Siding, Pressboard Lap

Siding, Vinyl

Siding, Wood

Trim, OSB

Trim, Fiber Cement

Trim, Vinyl

Shingles, Tar or Wood

Do NOT Use on

High Pressure Laminate

or Solid Wood!

Replacement Blade for 113FLR is part #113B

Replacement Blade for 120FLR is part #120B