WARNING

Very Sharp Blade

!

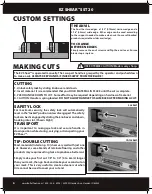

Set up

3. AttAcH tAble

A

. Attach front of table to base,

using (6)

Item D

screws. Tighten

with #2 Phillips.

B

. Attach back of table to tail

using (4)

Item E

self

tapping

screws. Tighten with #2 Phillips.

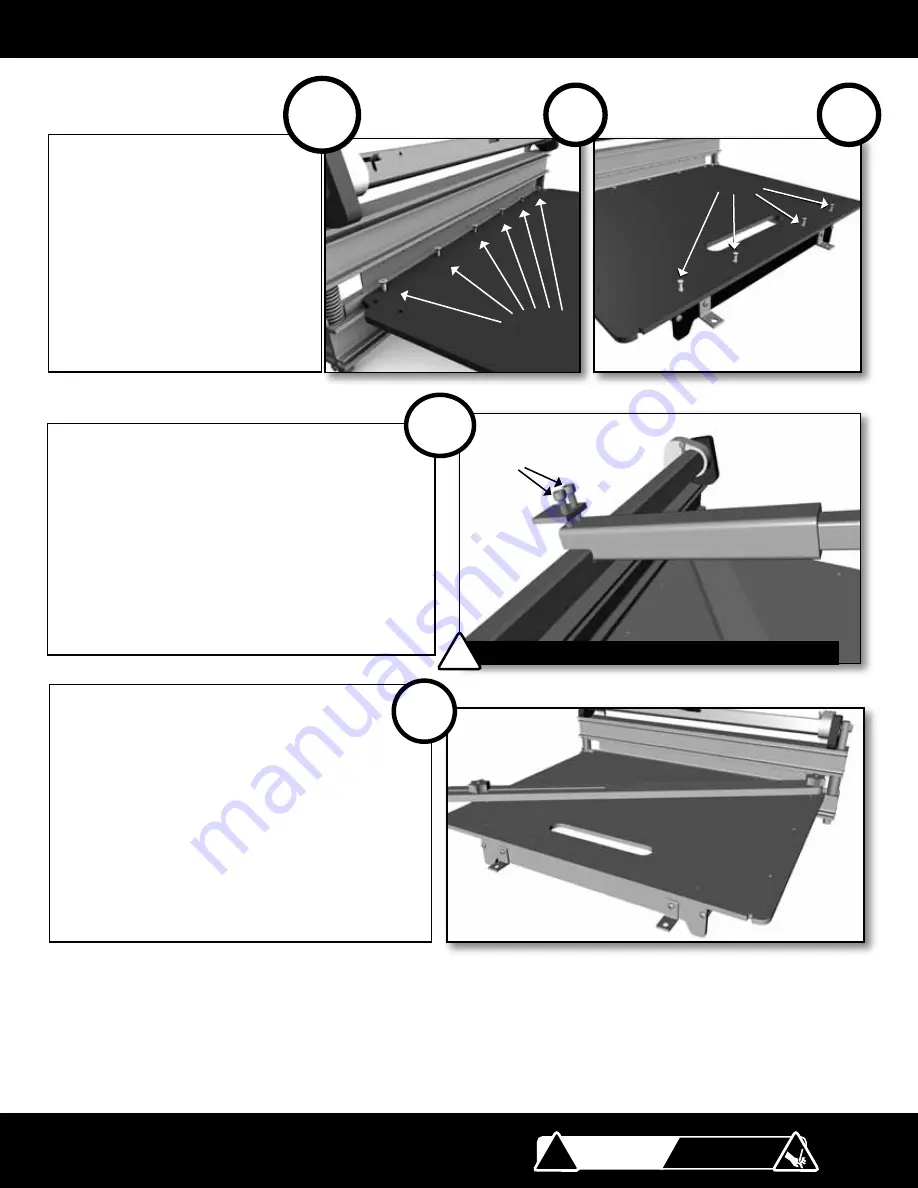

4. to AttAcH HAndle:

Insert (2)

Item F

screws through back stroke

stop, and tighten with

Item G

hex wrench.

Note: To ensure correct alignment, start each

of the bolts by hand before using

Item G

hex

wrench.

5.

AttAcH Fence

Slide fixed clamp into the front quick alignment

notch.

For 90° cuts, slide loose clamp into rear

alignment notch and tighten star knob.

For angle cuts:

1) Align edge of fence with the desired angle

guide mark in center of table.

2) Slide loose clamp to edge of table and tighten

star knob.

3

3b

4

5

3A

Handle under pressure

- do not allow to slam back!

!

Item E

Item D

Item F

Tail

6.

replAcing tHe blAde

Follow the directions on Page 9 of the manual, using a

226B replacement blade

.

mAintenAnce

The SST 226 has the same maintenance requirements as the SST 220.

See Manual.

PRT-INS-M226 Rev.A-11.12 ©2012 Bullet Tools