MY21B01 - 12_1.0_25.06.2020

76

Cleaning and servicing

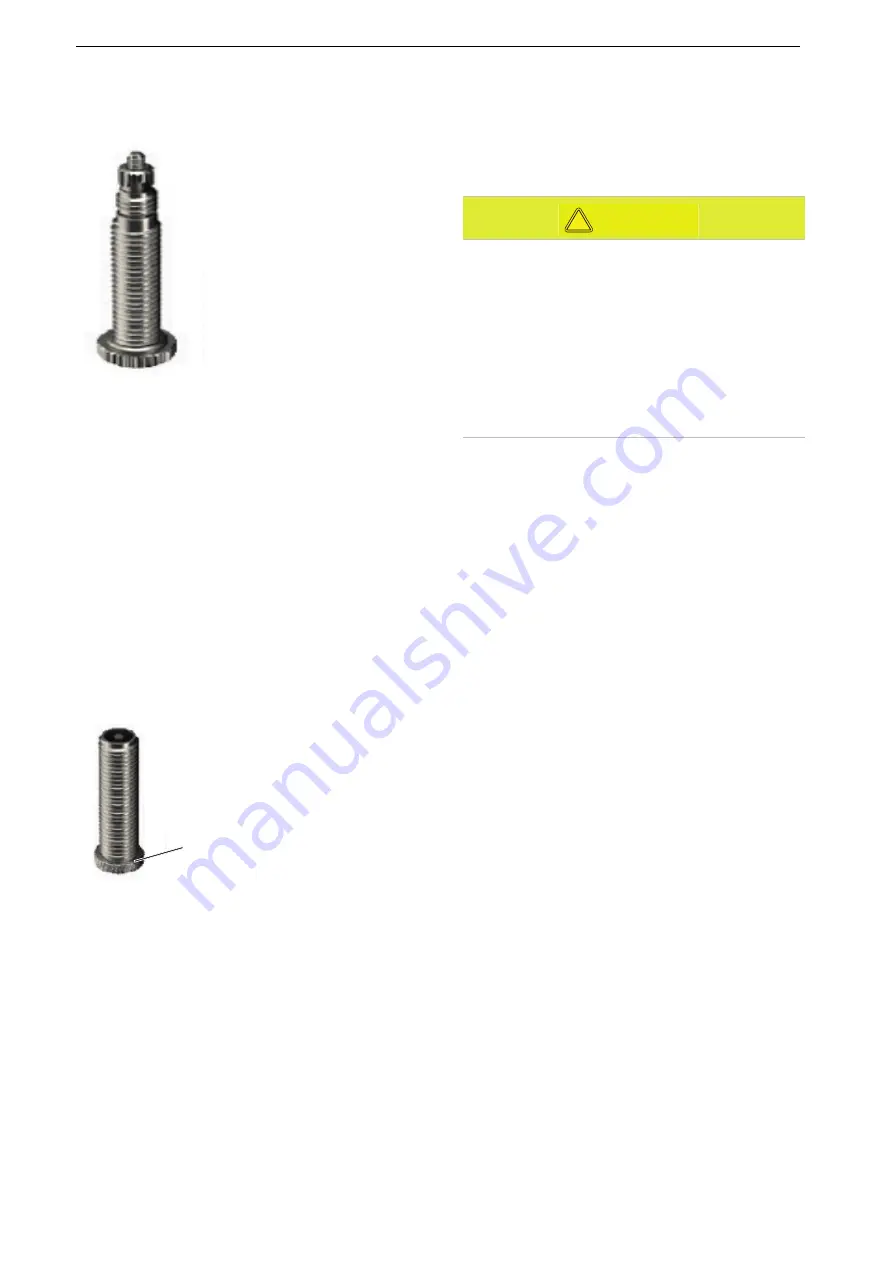

7.4.1.4 Checking and adjusting the tyre

pressure – Presta valve

Only applies to pedelecs with this equipment

It is recommendable to use

a bicycle pump with a

pressure gauge. The

operating instructions for

the bicycle pump must be

adhered to.

1

Unscrew and remove the

valve cap.

2

Open the knurled nut

around four turns.

3

Carefully apply the bicycle

pump so that the valve

insert is not bent.

4

Pump up the tyre slowly and pay attention to

the tyre pressure in the process.

5

Correct the tyre pressure as per the

specifications on the tyre.

6

Remove the bicycle pump.

7

Tighten the knurled nut with your fingers.

8

Screw the valve cap tight.

9

Screw the rim nut gently against the rim with

the tips of your fingers.

7.4.1.5 Checking and adjusting the tyre

pressure – Schrader valve

Only applies to pedelecs with this equipment

It is recommendable to use a

bicycle pump with a pressure

gauge. The operating

instructions for the bicycle

pump must be adhered to.

1

Unscrew and remove the

valve cap.

2

Attach the bicycle pump.

3

Pump up the tyre slowly and pay attention to

the tyre pressure in the process.

The tyre pressure has been adjusted as per the

specifications.

4

Remove the bicycle pump.

5

Screw the valve cap tight.

6

Screw the rim nut (1) gently against the rim

with the tips of your fingers.

7.4.2

Brake system

The maintenance interval for the brake depends

on the weather conditions and how frequent the

bicycle is used. If the pedelec is used under

extreme conditions such as rain, dirt or high

mileage, maintenance must be performed more

frequently.

7.4.3

Checking the brake linings for wear

Check brake linings after brake has been fully

applied 1,000 times.

1

Check that the brake linings are no less than

1.8 mm wide at any point and no less than

2.5 mm between the brake lining and

supporting plate.

2

Push brake lever and hold. In doing so, check

the transport safety wear gauge can fit

between the brake lining supporting plates.

The brake linings have not reached their wear

limit. Contact your specialist dealer if any of

these components are worn.

Crash caused by brake failure

Worn brake discs and brake linings, as well as a

lack of hydraulic fluid in the brake cable, reduce

the braking power. This may cause a crash with

injuries.

Check the brake disc, brake linings and

hydraulic brake system on a regular basis.

Contact your specialist dealer if any of these

components are worn.

CAUTION

!

1

Summary of Contents for 21-15-1016

Page 99: ...MY21B01 12_1 0_25 06 2020 99 Documents D Compact Charger A G A C EBE D F ...

Page 100: ...MY21B01 12_1 0_25 06 2020 100 Documents D EBE D F A G A C ...

Page 101: ...MY21B01 12_1 0_25 06 2020 101 Documents D A G A C EBE D F ...

Page 109: ...MY21B01 12_1 0_25 06 2020 109 Appendix II Declaration of conformity for incomplete machine ...

Page 110: ...MY21B01 12_1 0_25 06 2020 110 Appendix ...