rdc-30-manual-en

Page 2 /

General

The RDC 30 Multidip is a machine designed for laboratory dip coating. They can be used to apply

liquid photoresist to e.g. miniature etching parts or other substrates, to apply liquid solder mask or

any other kind of protective or technical coating. Today a more and more popular application is

the so called: "sol-gel-application". This machine was developed to meet the demand of a greater

variety of speeds, iterations, dipping and dripping times and heavier workpieces. What is more:

With the RDC30 dipping sequences with different liquids can be performed in one machine and in

endless variations.

Features:

Rotary table with 6 cups for multi-coating!

Each dive individually programmable (diving, drawing speed, dipping and dropping time)

integrated magnetic stirrer with programmatic function and speed (1 - 999 1/min)

Diving and drawing speed between 1 - 9500 mm/min

Save this job and job iterations possible

Of course we try to realize your special demands. Please contact us!

Foil keyboard for easy data entry

Display 20 x 4

Stepper motor operated lift device

Stepper motor operated turning table

Setting of virtual offset position prevents unnecessary travel paths and saves time

Setting of virtual speed change position allows fast travel to overcome longer distances and slow

travels for precise coating

The dipping time as well as the drip-off-time (pause time up and down) is separately adjustable from

0 s up to 99h : 59min : 59s. This enables the machine not only to coat but to precisely develop. This

is of great importance with certain photo coatings of the miniature etching technology.

Up to 1000 iterations of a dip routine are possible.

Turning table with support for 6 vessels (cup glasses) D80mm, programmable positioning and stir-

ring device on board!

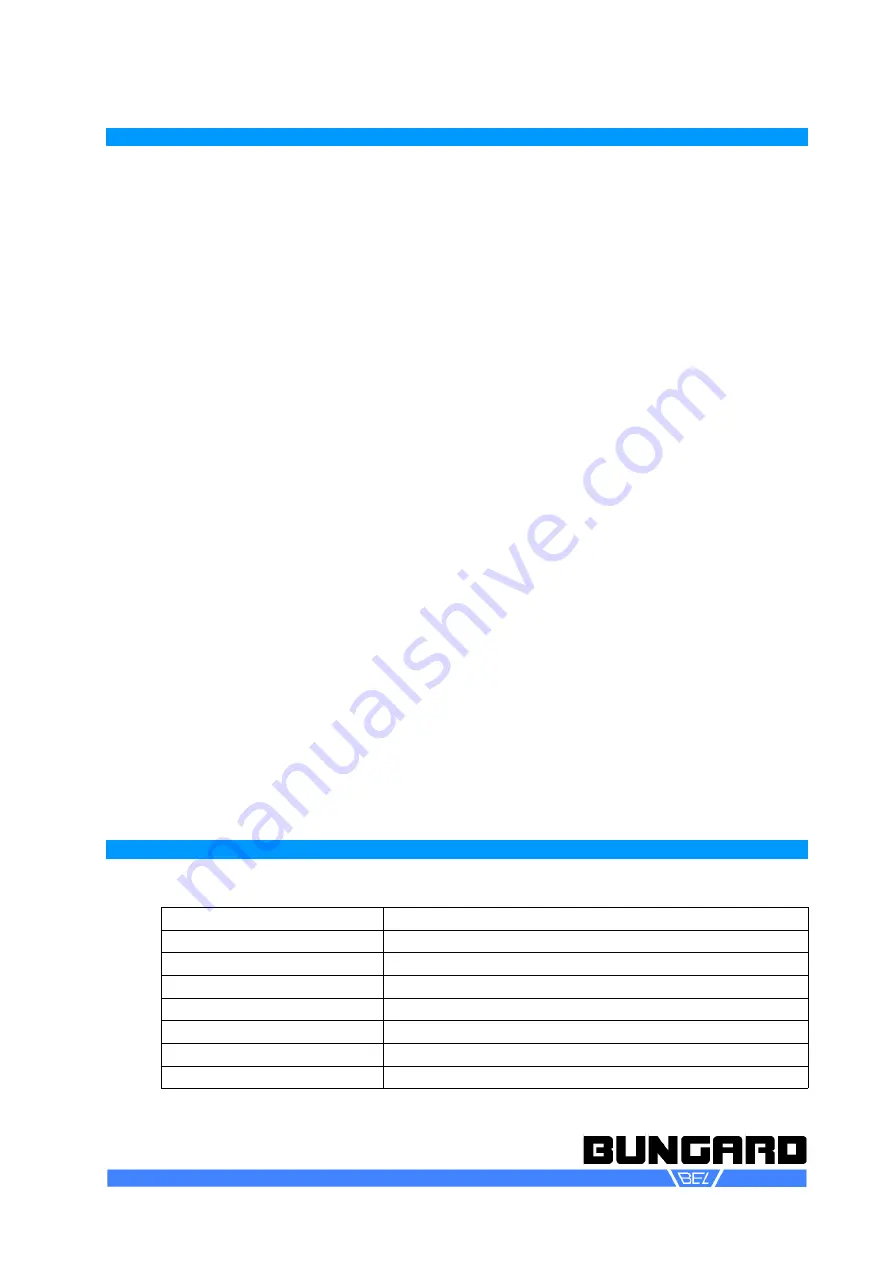

Technical Data

Stroke length:

575 mm

Maximum load:

3 kg (reduced max. speed with maximum load)

Weight:

15 kg

Dimensions (WxDxH):

330x470x1020mm (960mm without Controller)

Speed

3 – 9500 mm/min/min

Dipping / Drip off Time:

0s - 99h:59min:59 s

Power supply:

100-240 V, 50-60 Hz, 100 W

Turning Table:

Support for 6 vessels D80mm (other diameters possible)

Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany

Tel.: +49 (0) 2292/9 28 28 - 0, Fax: +49 (0) 2292/9 28 28 - 29, E-mail: support@bungard.de