RLM419p-Manual-E

Page 6 / 13

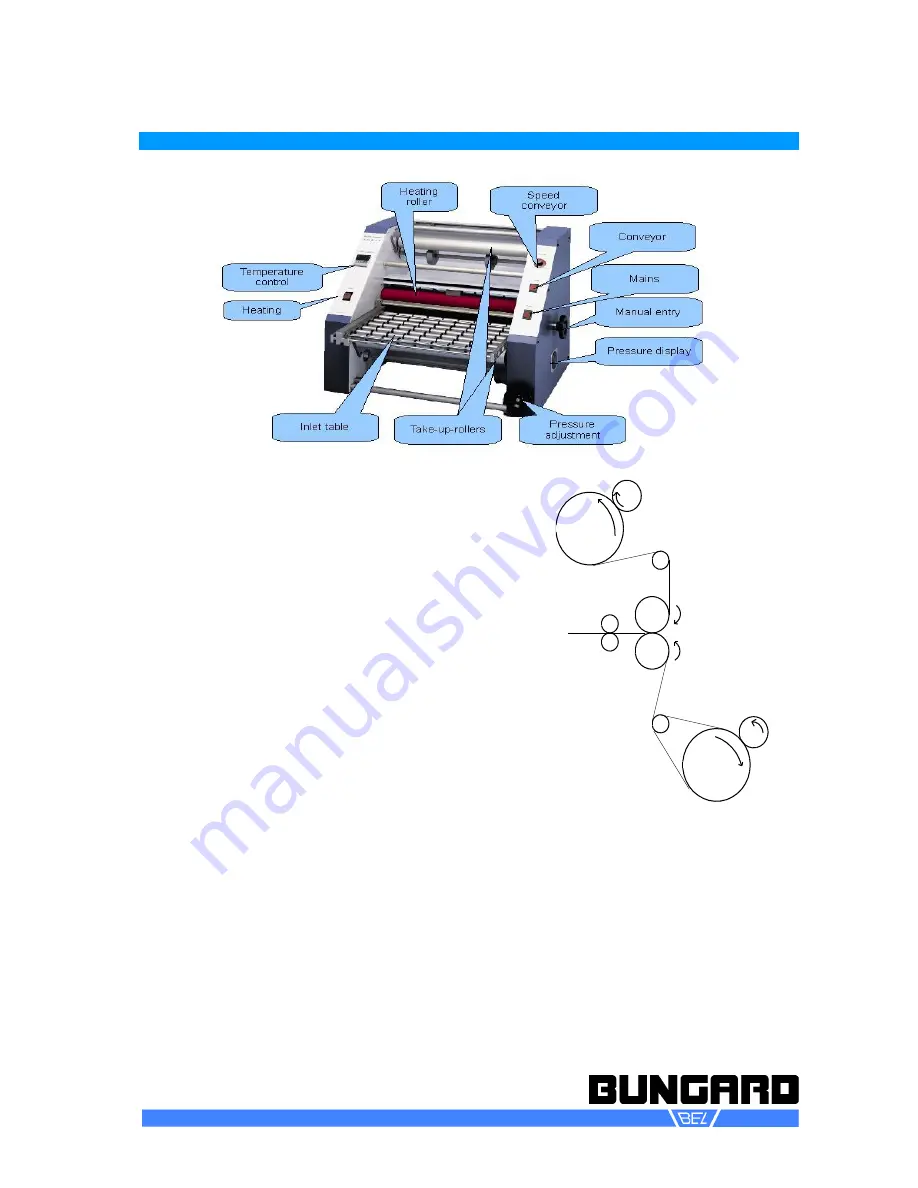

Short instructions

Examine the machine on delivery for any visible transport

damage and if there inform shipping agent and us immedi-

ately.

Read the instructions carefully and follow the safety instruc-

tions. Read the information for the laminates and observe the

material safety data sheets. Keep this manual in a safe

place. It contains information you might later on for mainten-

ance or cleaning.

Remove the packaging and set the laminator to its destina-

tion. Unpack all the accessories (2 hand wheels, power cord,

4mm Allen wrench, inlet table). Mount one hand wheel for

pressure adjustment at the front of the machine and the other

on the right side for manual board transport.

The photo laminates are light sensitive. For this reason, the

RLM 419p is usually operated in a yellow light room. UV Fil-

ter foils and tubes can be purchased through us.

Connect the laminator to 230 V 50 Hz and do a functional

test: turn on main switch - a welcome message with version

number appears on the controller display. After some

seconds the actual and the target temperature are displayed.

Turn on the transport and check the speed of adjustment.

Turn the heating on and control that the heating rolls warm up and the actual temperature increases

in the display. Caution! Danger of burns! You can adjust the target temperature by pressing the "C"

key and then use the arrow keys to adjust the desired temperature. Press OK (the green "Enter"

key) to leave the temperature setting and store the value.

Mount either tenting resist or solder mask on both laminate rolls according to the roller schematic.

For tenting resist set pressure to 1-2 and temperature to 105°C. For solder mask set pressure to 4-5

and temperature to 115°C.

Set transport speed to 0.5 m / min and perform a laminating test.

Turn off the laminator and let the rollers cool down.

Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany

Tel.: +49 2292 / 9 28 28-0, Fax: +49 2292 / 9 28 28-29

, E-mail: support@bungard.de

roller schematic

Transport / Lamination rollers

Transport / Laminierwalze

Guide roller

Umlenkrolle

Take-up roller

Aufwickelrolle

Laminate coil

Laminatrolle

Take-up roller

Aufwickelrolle

Laminate coil

Laminatrolle