Page 29

TR

M2

J1

J2

J3

J4

J5

J6

J7

TR

M1

TR

M2

J1

J2

J3

J4

J5

J6

J7

TR

M1

CAUTION

DISC

AR

D D

EC

AN

TER

IF:

. C

RA

CK

ED

. S

CR

AT

CH

ED

. B

OI

LE

D D

RY

. H

EA

TE

D W

HE

N E

MP

TY

. U

SE

D O

N H

IG

H

FL

AM

E

. O

R

EX

PO

SE

D

ELE

CTR

IC

E

LE

ME

NT

S

FA

ILUR

E TO C

OM

PLY

R

ISK

S IN

JUR

Y

PN

: 65

8

19

85

B

UNN

-O

-M

AT

IC

C

OR

PO

RA

TIO

N

FUN

NEL C

ON

TEN

TS

A

RE HO

T

!

CAUTION :

W

AR

M

ER

S

AN

D S

UR

FA

CE

S A

RE

H

OT

ON

/LOW

ER

START

FRO

NT-S

IDE-R

EAR

CAUTION :

W

AR

M

ER

S A

ND

S

UR

FA

CE

S

AR

E

HO

T

ON

/LOW

ER

STA

RT

FRO

NT-SIDE

-R

EAR

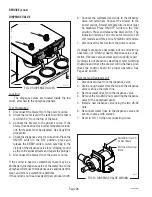

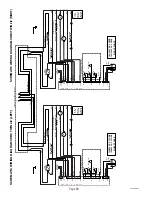

LIMIT THERMOSTAT

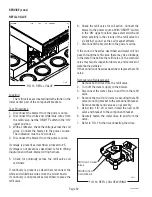

Location:

The limit thermostats are located inside the front

access panel on the front side of the tanks.

Test Procedures:

1. Disconnect the brewer from the power source.

2. Disconnect the blue and black wires from the limit

thermostat.

3. With an ohmmeter, check for continuity across the

limit thermostat terminals.

If continuity is present as described, the limit thermo-

stat is operating properly.

If continuity is not present as described, replace the

limit thermostat.

P1800

P1878

SERVICE (cont.)

BLU from Control

Board

BLK from Terminal

Block

FIG. 11 LIMIT THERMOSTATS

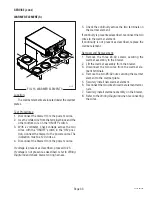

Removal and Replacement:

1. Remove the black and blue wires from limit ther-

mostat terminals.

2. Carefully slide the limit thermostat out from under

the retaining clip and remove limit thermostat.

3. Carefully slide the new limit thermostat into the

retaining clip.

4. Refer to FIG. 12 when reconnecting the wires.

FIG. 12 LIMIT THERMOSTAT WIRING

29319 091203