Page 4

CAUTION – Improper electrical installation will damage electronic components.

1. An electrician must provide electrical service as specified.

2. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

3. Remove the front panel beneath the sprayheads.

Models with electronic control assemblies:

Place the tank heater switch at the top of the control assembly in the “OFF” position.

Models with electro/mechanical thermostats:

Rotate the control thermostat knob fully counterclockwise to the “OFF” position.

4. Feed the cord through the strain relief and connect it to the terminal block.

5. Connect the brewer to the power source and verify the voltage at the terminal block before proceeding. Re-

place the front panel.

6. If plumbing is to be hooked up later be sure the brewer is disconnected from the power source. If plumbing

has been hooked up, the brewer is ready for Initial Set-Up.

PLUMBING REQUIREMENTS

This brewer must be connected to a cold water system with operating pressure between 20 and 90 psi (138

and 620 kPa) from a

1

⁄

2

" or larger supply line. A shut-off valve should be installed in the line before the brewer.

Install a regulator in the line when pressure is greater than 90 psi (620 kPa) to reduce it to 50 psi (345 kPa).

The water inlet fitting is

1

⁄

4

" flare.

NOTE – Bunn-O-Matic recommends

1

⁄

4

" copper tubing for installations of less than 25 feet and

3

⁄

8

" for more than 25

feet from the

1

⁄

2

" water supply line. A tight coil of copper tubing in the water line will facilitate moving the brewer

to clean the countertop. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The

size and shape of the hole made in the supply line by this type of device may restrict water flow.

This equipment must be installed to comply with the International Plumbing Code of the International

Code Council and the Food Code Manual of the Food and Drug Administration (FDA). For models in-

stalled outside the U.S.A., you must comply with the applicable Plumbing/Sanitation Code for your area.

NOTE - If a backflow preventer is required by code, a shock arrestor should be installed between backflow pre-

27040 011108

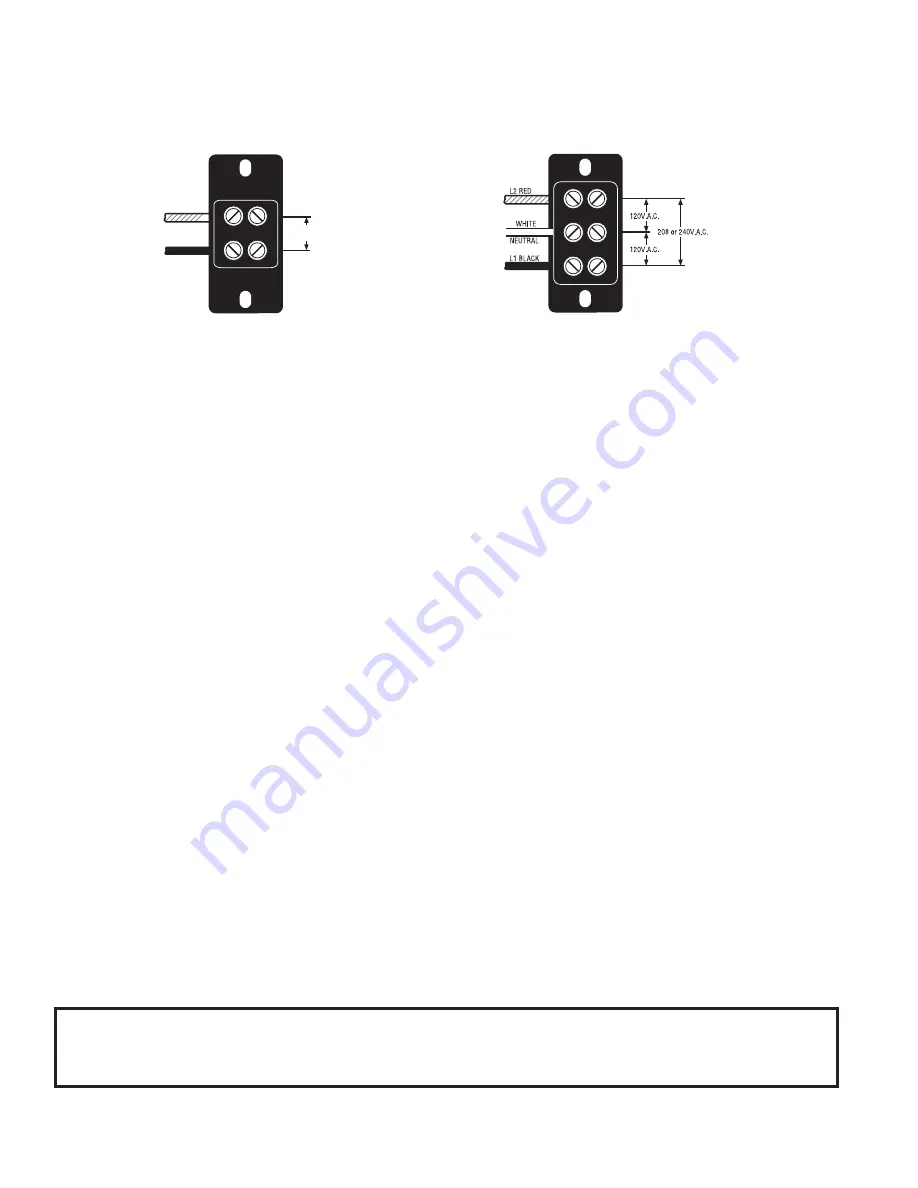

Electrical Hook-Up

L2 RED

L1 BLACK

200, 230 or

240V A.C.

ELECTRICAL REQUIREMENTS

WARNING - The brewer must be disconnected from the power source until specified in

Initial Set-Up.

Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements.

200, 230 & 240 volt ac models

Note: This electrical service consists of 2

current carrying conductors (L1 and L2) and

a separate conductor for earth ground.

120/208 & 120/240 volt ac models

Note: This electrical service consists of 3 current

carrying conductors (Neutral, L1 and L2) and a

separate conductor for earth ground.