32

SERVICE (cont.)

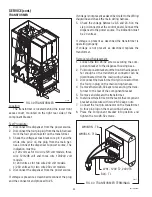

OVERFLOW PROTECTION SWITCH

P1637

FIG. 26 OVERFLOW PROTECTION

SWITCH LEADS

P1212

RED to BLK Wire

from Main Harness

RED to BLU Lead

from Main Harness

FIG. 25 OVERFLOW PROTECTION SWITCH

Location:

The overflow protection switch is located inside

the copper overflow cup on the left side of the tank.

Test Procedures:

1. Disconnect the dispenser from the power

source.

2. Remove the wire nuts connecting the red wires

from the overflow protection switch to the black

wire and blue wire from the main harness.

3. Check for continuity across the safety overflow

switch red wires only until the plastic float is raised

and check that continuity returns when the plastic

float is again lowered.

If continuity is present as described, reconnect the

red wires to the black wire and the blue wire from

the main harness.

If continuity is not present as described, replace the

overflow protection switch.

29170 080900

Removal and Replacement:

1. Disconnect the red leads from the overflow protec-

tion switch from the black wire and the blue wire

from the main harness.

2. Remove the nut beneath the copper overflow

cup.

3. Remove the entire switch assembly from the

cup.

4. Place the new switch assembly into the cup, wires

first. Make sure that a gasket is in place around

the threaded switch stem.

NOTE -

The magnets must be at the top of float and

there must be NO adjusting washers installed for the

overflow protection switch to operate properly.

5. Install the nut beneath the copper overflow cup.

Be sure not to overtighten.

6. Refer to Fig. 26 when reconnecting wires.

Summary of Contents for FMD-3

Page 41: ...41 29170 091598 ...

Page 42: ...42 29170 080900 ...