21

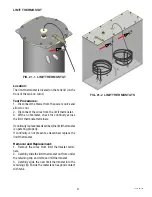

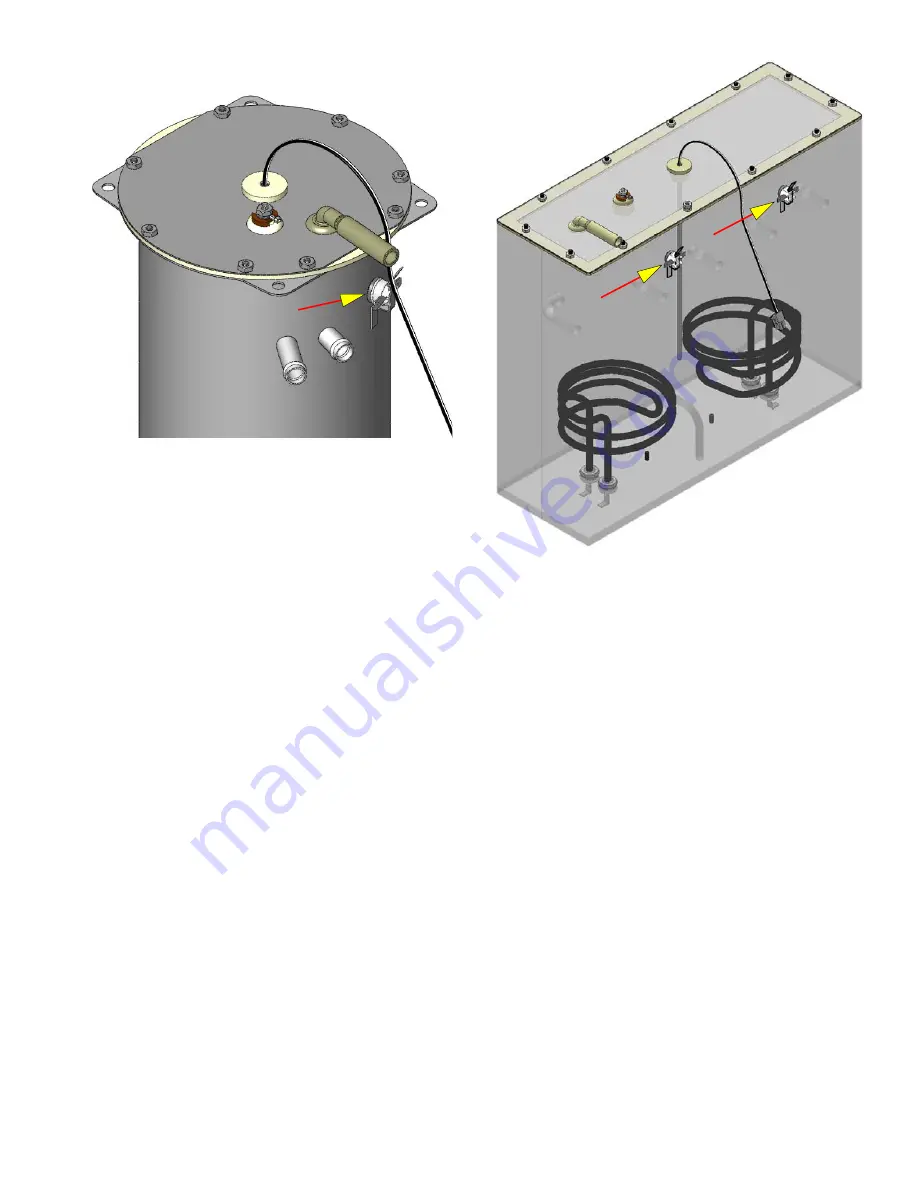

LIMIT THERMOSTAT

Location:

The limit thermostat is located on the tank lid (on the

front of the tank on twins).

Test Procedures:

1. Disconnect the brewer from the power source and

allow to cool.

2. Disconnect the wires from the limit thermostat.

3. With an ohmmeter, check for continuity across

the limit thermostat terminals.

If continuity is present as described, the limit thermostat

is operating properly.

If continuity is not present as described, replace the

limit thermostat.

Removal and Replacement:

1. Remove the wires from limit thermostat termi-

nals.

2. Carefully slide the limit thermostat out from under

the retaining clip and remove limit thermostat.

3. Carefully slide the new limit thermostat into the

retaining clip. Ensure the metal face has good contact

with tank.

FIG. 21-1 LIMIT THERMOSTAT

FIG. 21-2 LIMIT THERMOSTATS

42461 081310

Summary of Contents for ICB

Page 37: ...37 ...