8

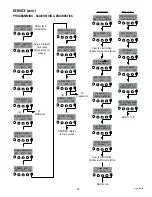

TROUBLESHOOTING (cont.)

PROBLEM

PROBABLE CAUSE

REMEDY

Place an empty container beneath the dispense

tip. Initiate a dispense cycle and check water

temperature immediately below the dispense

tip with a thermometer. Repeat until maximum

temperature is reached. Reading should be 185

– 190°F. Adjust tank temperature setting using

programming menus.

Test whipper motor circuit, see “TEST DISPENSE

HEAD ?” under “DIAGNOSTICS ?” menu.

Check that frother is properly installed; refer to

cleaning decal inside front door.

Test dispense solenoid valve flow rate. In the

“RINSE” mode, momentarily press dispense

switch, and catch water in calibrated container.

Unit should dispense 12±.5 oz during 10 second

rinse cycle.

Test auger motor circuit, see “TEST DISPENSE

HEAD ?” under “DIAGNOSTICS ?” menu

Check that auger spring is properly installed, re-

fer to cleaning decal inside of front door.

Check that switch is set in the “NORMAL” posi-

tion.

Refill hopper with correct product

Check throw weight

Plumbing lines should not be resting on the

counter top.

Water pressure to the dispenser not to exceed

90 psi (620 kPa) Install a regulator if necessary

to lower the working pressure to approximately

50 psi (345kPa).

Remove and clean lime off tank heater

Check for cleanliness and correct installation of

chamber and frother

(A) remove powder tray and clean as required

(B) check that air is blowing from slots in dis-

penser bottom panel.

Replace lamp if required

Disconnect ballast from power supply, check for

continuity between two black leads.

Check Night Mode Switch

1. Water temperature

2. Whipper motor

3. Frother

4. Dispense solenoid valve

5. Auger motor

6. Auger spring

7. NORMAL/PROGRAM/RINSE switch

8. Hopper out of product

9. Incorrect throw weight

1. Plumbing lines

2. Water Supply

3. Tank heater

4. Frother

1. Fan

1. Lamp

2. Ballast

3. Night Mode

Weak product

Dispenser making unusual noises

Excessive dust

Display not lit

42032 060109

Summary of Contents for IMIX

Page 10: ...10 42032 060109 NOTES ...

Page 46: ...46 42032 060109 ...

Page 48: ...48 42032 060109 ...