14

4. At the end of the 5 second period, the selected position will dispense water (no concentrate) for only 3 sec-

onds.

5. Measure the water dispensed.

6. Adjust the water flow rate Fig 7, (clockwise to increase flow rate; counterclockwise to decrease flow rate) to

the corresponding product mix ratio as follows:

7. Repeat steps 3 through 6 as necessary until the correct water flow rate is achieved.

8. Repeat steps 3 through 7 for the remaining dispense positions.

9. Exit the “Pump Speed Programming” mode by simultaneously pressing both “Hidden Switches”. Note that

the beeper sounds twice and the “PROGRAM” indicator extinguishes.

Pump Speed Programming

1. Enter the “Pump Speed Programming” mode by simultaneously pressing both “Hidden Switches”. Note that

the beeper sounds twice and that the “PROGRAM” indicator begins flashing.

2. To increase the pump speed, press and hold the right-hand “Hidden Switch” (filled circle) and then momen-

tarily press the “Product Dispense Switch” Fig 4 (“+/STOP Switch” Fig 5, for portion control dispensers).

Each time the “Product Dispense Switch “(+/STOP Switch”) is pressed, the motor speed is increased by one

step (5 revolutions per minute [RPM].) Note that each step is confirmed by a single flash of the appropriate

“REFILL” indicator and a single tone from the beeper.

ADJUSTMENT & OPTIONAL SETTINGS (cont)

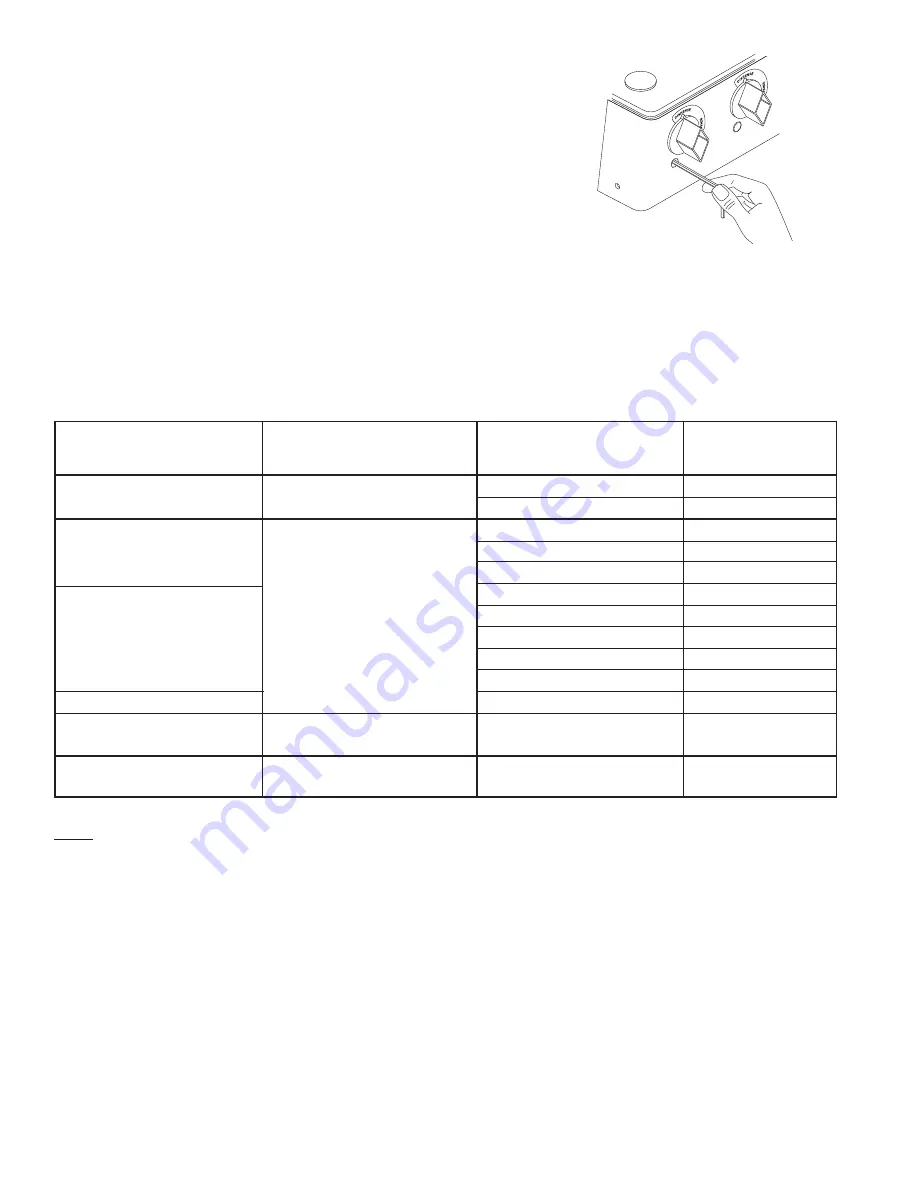

FIG 7 Adjusting Water Flow

Using 1/4” allen wrench

Mix Ratio

Adjust water flow rate to:

Product

Brix %

(water + concentrate)

2+1

*3.75 fl. oz (111 ml)

Prune Juice

16.0%

per 3-second test

Other

*

Orange Juice

11.8%

4+1

Pineapple Juice

12.8%

Cranberry Fruit Cocktail

14.0%

*4.0 fl. oz (118 ml)

Grapefruit Juice

10.6%

per 3-second test

Lemonade

5+1

Apple Juice

12.0%

Fruit Punch

Grape Juice

13.0%

3+1 through 7+1

Other

*

Above 7+1

*4.0 fl. oz (118 ml)

Other

*

per 3-second test

High Viscosity Juice

2.25 - 3.0 fl. oz (66.5 - 89 ml)

As Required

-

per 3-second test

*Maximum flow rate may be less depending on the water pressure supply at each location.

Note: Information for specific products listed in this table is to be used for reference only. Consult the product

label for exact mix ratio and/or brix %. See product label for target brix %.

Water Flow Testing and Adjustment

1. Enter the “Pump Speed Programming” mode by simultaneously press-

ing both “Hidden Switches” Fig 4 or Fig 5. Note that the beeper sounds

twice and that the “PROGRAM” indicator begins flashing.

2. Place a graduated measuring cup or the large chamber of the empty

brixing cup (BUNN-O-MATIC part number 33095.0000) under the ap-

propriate dispense nozzle.

3. Press and hold the desired “Product Dispense Switch” Fig 4 (“+/Stop

Switch” Fig 5, for portion control dispensers) for 5 seconds. Note

that the beeper sounds once per second (6 times, total) during this

period.

38218.1 030306