JDF Silver Series Training Manual

16

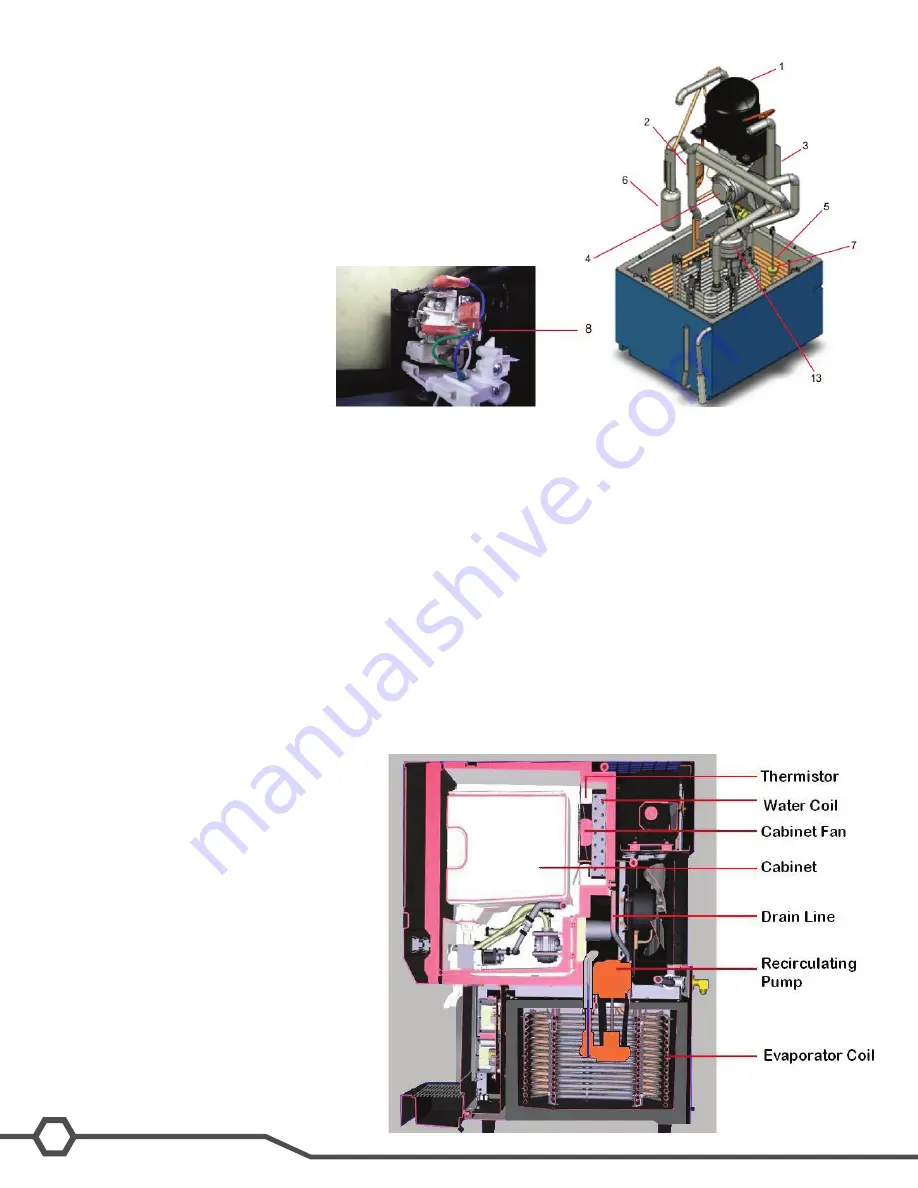

Refrigeration System

The components that make up the refrigeration system to create an ice

bank are compressor (1), filter dryer with capillary tube (2), condenser

(3), condenser fan (4), evaporator (5) and accumulator (6). The other

components that are responsible for monitoring the ice bank and turn-

ing on/off of the compressor are as follows; thermistor (7), start relay (8),

run relay, transformer and main control board.

Upon initial plug-in or power up, the main control board will monitor the

bath thermistor and go through a six minute delay sequence before sup-

plying 120VAC to the compressor

relay coil. After the six minute de-

lay, the run relay coil will energize,

power cannot pass through the

relay contacts until the refrigeration

switch is turned to supply power to

the compressor.

Power passes through the limit thermostat and powers the start relay mounted on the compressor. The unit will take

several hours to create the ice bank required for full dispenser performance. During this time, some further trickling

from the water bath is expected due to expansion caused by the ice bank formation. When the temperature reaches

27º F, this will shut off the 120VAC to the compressor run relay coil. As the ice block thaws, temperature rises to 32º

F, the CBA will again supply 120VAC to the compressor run relay coil to start the compressor. Anytime the machine is

powered down electrically, the refrigeration system will have a six minute delay starting the compressor.

The delay ensures enough allowable time for the start relay (PTC) resistance to decrease to complete the start wind-

ing path for initial start up and refrigerant high and low pressure to stabilize.

Cabinet Cooling

First, the refrigeration system creates an ice block around the evaporator coil in the bath tank. The top load recircu-

lating pump is mounted semi-centered in the bath tank and is activated by the refrigeration switch. Water is drawn

from the bath tank up to the top connection of the cabinet cooling coil and at the same time water is being bypassed

going directly back into the bath tank for increased agitation. The chilled water passes through the cabinet water coil

picking up heat before returning back to the bath tank along side of the recirculating pump. Water is being bypassed

at all times during this 24/7 recirculation process.

Meanwhile, a 24VDC cabinet fan operates

24/7 pulling and recirculating the cabinet

air across the cabinet water coil. This

speeds up the process of removing heat

from the cabinet air or decrease the cabinet

temperature. A thermistor located inside

the cabinet behind the fan panel monitors

the temperature. The CBA will receive the

low input voltage signal and will turn on the

corresponding temperature LED’s located

at the bottom of the CBA. The #5 green

LED indicates cabinet temperature is below

50º F and #4 red LED indicates cabinet

temperature is above 50º F. A thermistor

can also be used to detect rise in

temperature for a period of time and signal

a fault status. The nominal cabinet holding

temperature is expected to be at or below 41º F.

Summary of Contents for JDF Silver Series

Page 1: ...BUNN TECHNICAL TRAINING JDF Silver Series ...

Page 31: ......