Page 6

PLUMBING REQUIREMENTS

These brewers must be connected to a cold water system with operating pressure between 20 and 90 psi

(0.138 and 0.620 MPa) from a ½˝ or larger supply line. A shut-off valve should be installed in the line before

the brewer. Install a regulator in the line when pressure is greater than 90 psi (0.620 MPa) to reduce it to 50

psi (0.345 MPa). The water inlet fitting is .75-11.5 NH (HOSE THREAD). For convenience an elbow adaptor is

provided to convert to a ¼˝ flare fitting. Bunn-O-Matic does not recommend the use of a reverse-osmosis or

deionized water supply to this equipment.

NOTE - Bunn-O-Matic recommends ¼˝ copper tubing for installations of less than 25 feet and

3

⁄

8

" for more than

25 feet from the ½˝ water supply line. A tight coil of tubing in the water line will facilitate moving the brewer to

clean the countertop. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The

size and shape of the hole made in the supply line by this type of device may restrict water flow.

As directed in the International Plumbing Code of the International Code Council and the Food Code Manual

of the Food and Drug Administration (FDA), this equipment must be installed with adequate backflow pre-

vention to comply with federal, state and local codes. For models installed outside the U.S.A., you must

comply with the applicable Plumbing /Sanitation Code for your area.

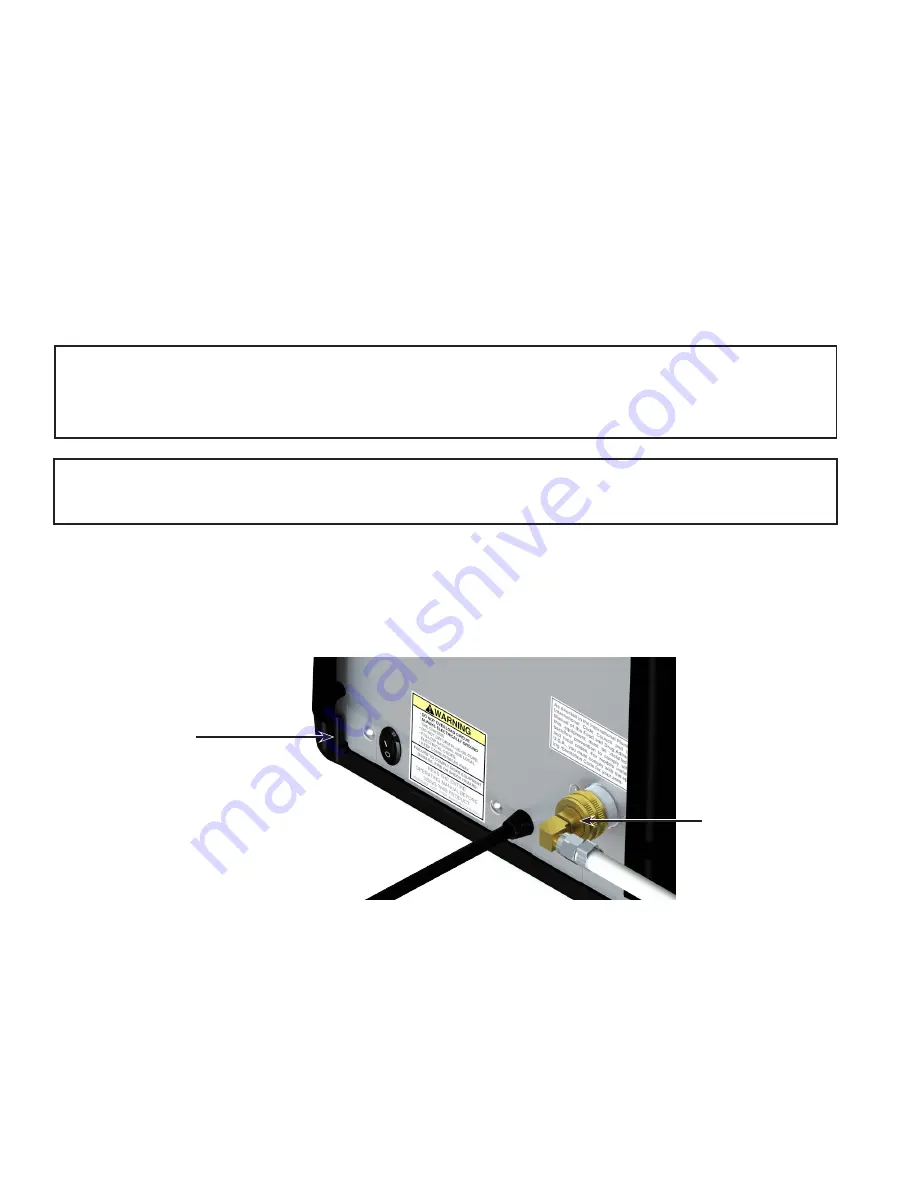

Plumbing Hook-Up

1. Flush the water line.

2. Securely attach the adaptor elbow assembly to the ¼˝ flare fitting on water supply line.

3. Securely attach adaptor elbow assembly to the the .75-11.5 NH fitting at the rear of the brewer.

4. Turn on the water supply.

NOTE - If a backflow preventer is required by code, a shock arrestor should be installed between backflow pre-

venter and dispenser. Installing the shock arrestor as close to the dispenser as possible will provide the best

results.

49251.0 081415

MAIN SWITCH

WATER LINE

CONNECTION

INITIAL SET-UP

1. Connect to power source.

2. Turn on main switch.

3. Wait approximately ten minutes for the tank to fill and heat. The display will read "READY TO BREW" when

tank reaches it's operating temperature.

4.

The brewer is now ready for use in accordance with the instructions for Coffee Brewing.