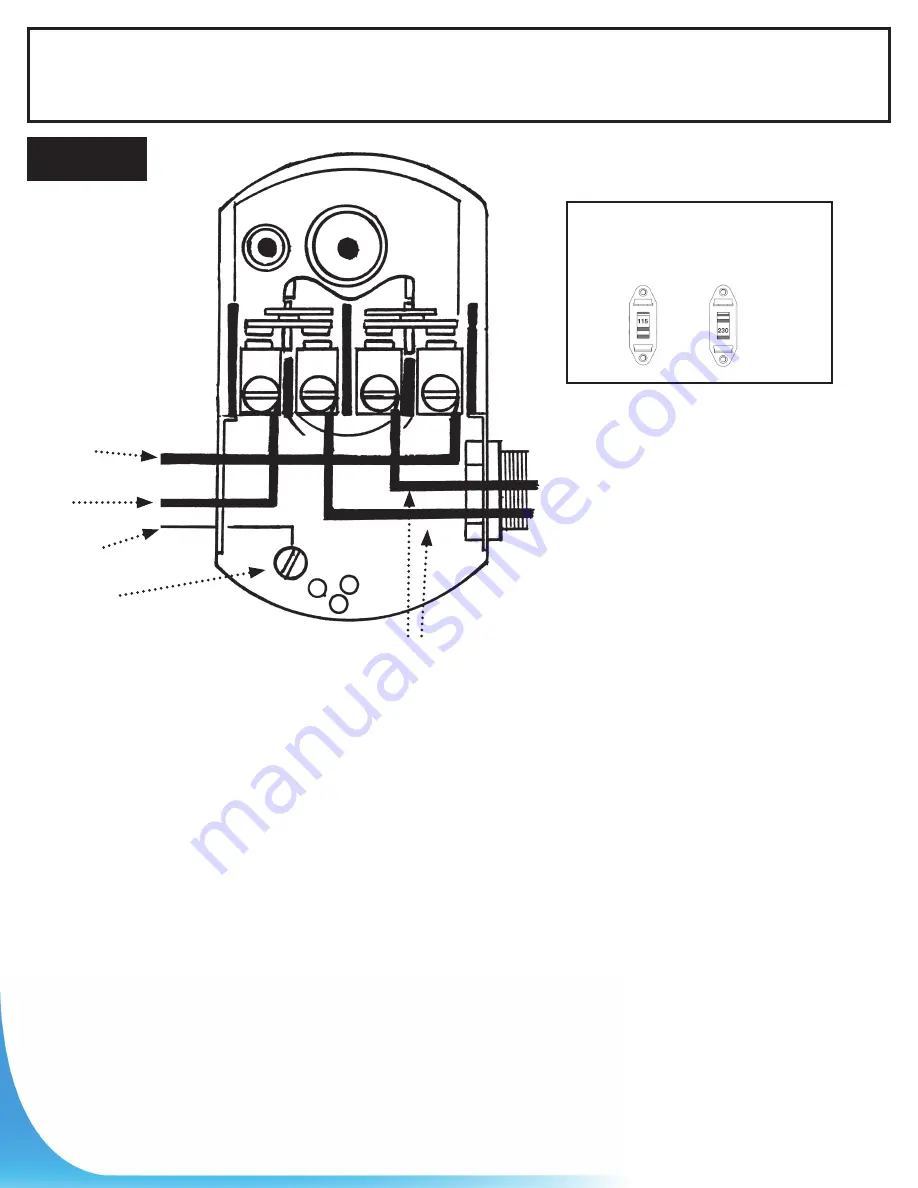

ELECTRICAL INSTALLATION

STEP 9

6

We recommend that a licensed electrician be employed to do the proper wiring to the pressure switch,

and to permanently ground the motor in accordance with the electrical codes in your area.

Do not use an extension cord to connect your pump to the power source. From your

distribution panel to the pressure switch, we recommend a wire gauge not smaller than 14 gauge.

This is a dual voltage 115/230 pump. The voltage selector switch is located inside the terminal box on the

motor. The motor is factory wired at 115V. For 230V selection, please open the terminal cover and set the

switch to the proper voltage. (See above drawing on right ).

The pressure switch setting (start/stop 20/40 or 30/50) has been made at the factory. Adjustments may be

done to give other operating pressures.

Adjustment or modification of start/stop setting of pressure switch has to be done carefully.

Turn the adjustment nut half a turn at a time.

Turn nut 1 clockwise to raise start and stop pressure setting.

Never turn nut 2. This will change the 20 PSI

range between start and stop pressure and may damage your tank’s bladder or modify the efficiency

of your water system.

Check system operation after each adjustment.

VOLTAGE SELECTION SWITCH

1. POWER

off.

2. Please

SELECT

the up knob position

for 115 V or down knob position for 230 V.

3. CONNECT to appropriate power source.

1

2

Electrical line

from home

distribution

panel.

BLACK

RED

GREEN

GROUND

To motor lead